Researchers have demonstrated a Cu-Al-Mn-based shape memory alloy that achieves unprecedented shape memory effect and high work output across cryogenic temperatures (50-270K), overcoming a fundamental limitation of conventional alloys. This breakthrough enables practical cryogenic actuators for space telescopes, superconductors, and liquid gas systems, validated by a functional mechanical heat switch prototype operating at 100K.

For decades, the dream of reliable, high-performance actuators operating in extreme cold has been limited by a fundamental materials constraint: Conventional shape memory alloys (SMAs) like Ti-Ni lose their signature shape-recovery properties below ~150K. Now, a breakthrough in Cu-Al-Mn-based alloys shatters this barrier, unlocking cryogenic actuation with exceptional force and displacement.

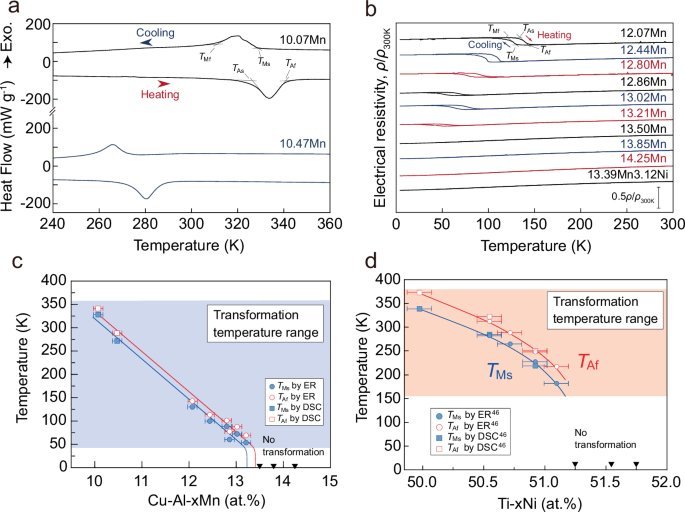

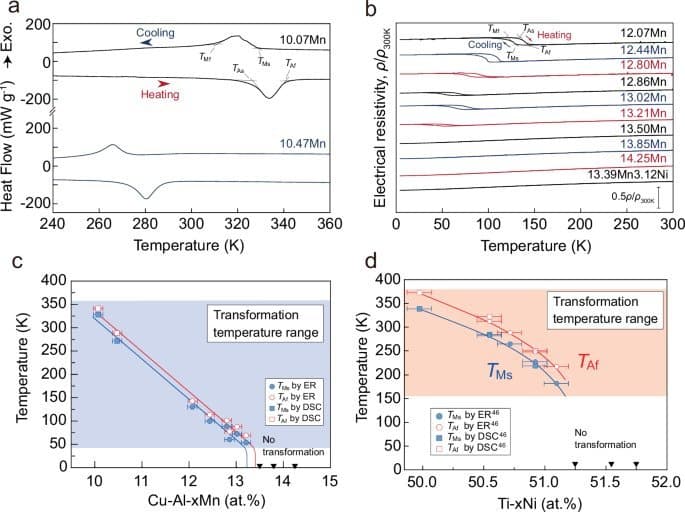

Caption: Transformation temperature comparison reveals Cu-Al-Mn's unique ability to maintain martensitic transformation down to ~50K, far below Ti-Ni's practical limit.

Caption: Transformation temperature comparison reveals Cu-Al-Mn's unique ability to maintain martensitic transformation down to ~50K, far below Ti-Ni's practical limit.

The Cryogenic Actuation Gap

Shape memory alloys (SMAs) are prized actuators, converting thermal energy into substantial mechanical work via reversible martensitic transformations. Their high energy density outperforms piezoelectrics and magnetostrictives. However, their utility plummeted in cryogenic environments essential for:

- Space Astronomy: Cooling infrared telescopes (e.g., ~100K for instruments like SPICA)

- Superconductivity: Managing components in liquid helium/nitrogen systems

- Liquid Hydrogen Infrastructure: Valves and controls for carbon-neutral energy

Traditional SMAs fail here because the entropy difference (ΔS) between martensite and parent phases vanishes near 0K, eliminating the thermodynamic driving force for transformation. Ti-Ni alloys also suffer from exploding hysteresis below ~150K, making controlled actuation impossible.

Cu-Al-Mn: Defying Thermodynamic Expectations

A team from Tohoku University, JAXA, and NAOJ engineered Cu-Al-Mn alloys with precise Mn content (up to 14.25 at.%) to systematically lower transformation temperatures. Single-crystal specimens exhibited remarkable properties under tensile testing (isobaric cooling-heating cycles):

- Operating Range: Stable shape memory effect observed from 50K to 270K – the widest cryogenic range reported.

- Work Output: Achieved up to 107 J·m⁻³ at 100K, dwarfing piezoelectrics (typically < 1 J·m⁻³) and magnetostrictives at similar temperatures.

- Low Hysteresis: Thermal hysteresis (TAf - TMs) remained small (~10-50K) even below 100K, unlike Ti-Ni.

The Key Anomaly: Crucially, entropy difference (ΔS) remained nearly constant down to 50K (Fig. 3c), defying the trend in other SMAs where ΔS collapses. This unique behavior, confirmed via specific heat measurements and Clausius-Clapeyron analysis (∂σ/∂T = -ΔS/(ε_tr·V_m)), enables the sustained work output.

From Lab to Space: The Cryogenic Heat Switch

Demonstrating real-world utility, the team built a mechanical heat switch for space telescope thermal management:

- Design: A Cu-Al-Mn single crystal (CAM#2) linked to bias springs and drive unit.

- Operation at ~100K:

- Cooling (Switch ON): Martensite formation elongates the alloy, pushing the drive unit to contact the cold plate, enabling heat transfer.

- Heating (Switch OFF): SME contraction retracts the unit, breaking thermal contact to isolate a failed cryocooler.

- Impact: This proof-of-concept enables simpler, lighter redundant cooling systems for missions, vital for high-sensitivity infrared astronomy.

Why This Matters Beyond Space

Cu-Al-Mn's cryogenic prowess isn't just a lab curiosity. It fills a critical gap in actuator technology:

- Enables New Applications: Reliable actuators for superconducting magnet quench protection, LNG/LH2 valve control, and quantum computing infrastructure.

- Material Advantages: Superior cold-workability vs. brittle Cu-Al-Ni/Cu-Zn-Al alloys, and higher work density than competing cryogenic actuators.

- Fundamental Insight: The persistent ΔS challenges assumptions about martensitic transformations near 0K, opening new research pathways.

As demand for cryogenic systems surges—driven by space exploration, clean energy, and advanced computing—this alloy family provides the missing link: robust, high-strain actuation where it was once deemed thermodynamically impossible. The era of cryogenic shape memory alloys has truly begun.

Comments

Please log in or register to join the discussion