University of Pennsylvania researchers have developed Diamanti—a revolutionary concrete blend and 3D-printing technique that mimics bone structures to reduce material use by 60% while boosting CO₂ absorption by 142%. This dual approach tackles concrete's 8% global emissions footprint through bio-inspired lattice designs and diatomaceous earth additives. The team is now preparing to construct its first full-scale prototype bridge in France.

The Concrete Revolution: How Bone-Inspired 3D Printing Could Reshape Construction

Concrete shapes our world—from skyscrapers to sidewalks—but at a staggering environmental cost: 8% of global CO₂ emissions stem from its production. For decades, the industry has pursued incremental sustainability gains through mixture tweaks or efficiency drives. Now, a breakthrough from the University of Pennsylvania’s Polyhedral Structures Laboratory offers a radical two-pronged solution merging material science with nature-inspired design.

Engineering Lessons from Evolution

Led by Dr. Masoud Akbarzadeh, the Diamanti project draws inspiration from biological structures like bone. "Through millions of years of evolution, nature learned you don’t need material everywhere," Akbarzadeh explains. "Bones are porous yet incredibly strong because of optimized load-bearing pathways."

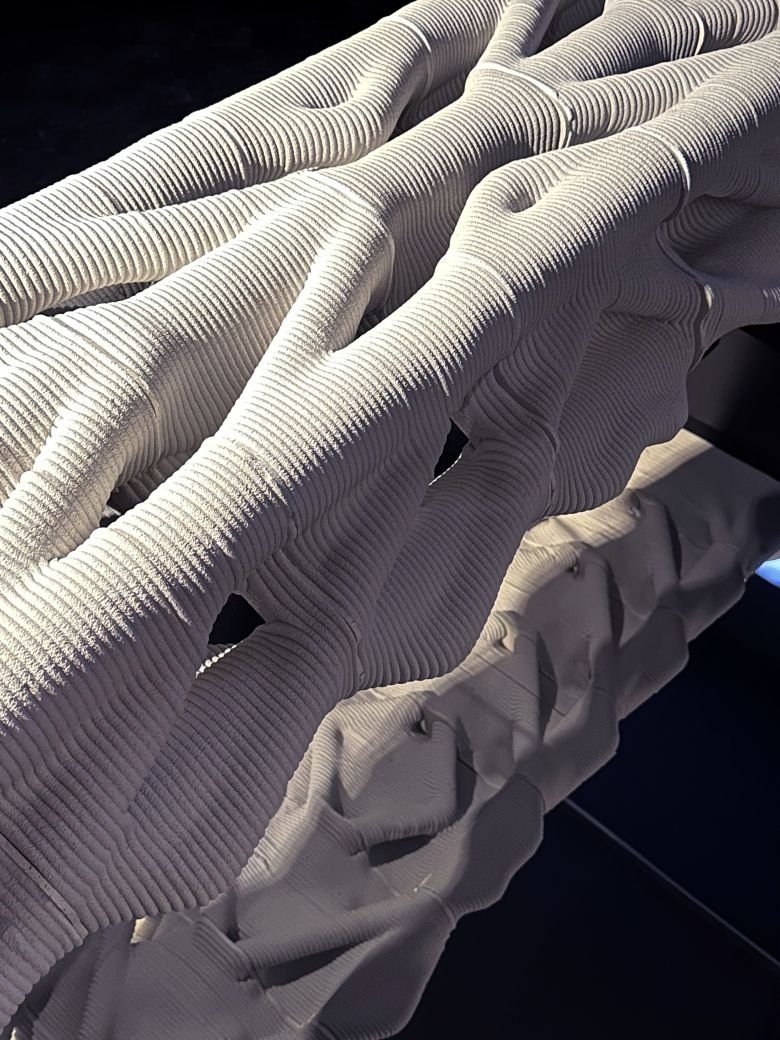

The team replicated these triply periodic minimal surface (TPMS) structures using robotic 3D printers to create intricate lattice patterns. This approach slashes material requirements by 60% while maintaining structural integrity. Crucially, the complex geometry also increases surface area by 30%—creating more "skin" for carbon absorption.

The Algae-Powered Chemistry

Material innovation complements the structural approach. Dr. Shu Yang’s team replaced cement—concrete’s most emissions-intensive component—with diatomaceous earth (DE), a silica-rich powder from fossilized algae. DE’s microporous structure acts like a CO₂ sponge, enabling deeper gas penetration than traditional concrete. Lab tests confirmed the hybrid mixture absorbs 142% more carbon dioxide than conventional formulas.

"The surface area, together with this material property, maximizes reaction with carbon at the microscopic level," notes Akbarzadeh. "This dual mechanism significantly contributes to emissions reduction."

From Lab to Load Testing

The team validated their approach through progressively ambitious prototypes:

- Robotic 3D printing eliminated formwork waste and cut energy use by 25%

- Tensile cable connections reduced steel requirements by 80%

- A 10-meter bridge segment passed structural load tests "beyond expectations"

While diatomaceous earth’s limited global supply (2.6M tons/year) poses scalability challenges, National University of Singapore’s Dr. Du Hongjian observes: "Even without the material innovation, the increased surface area alone boosts CO₂ absorption potential."

The French Connection

After conceptual renders envisioned Diamanti spanning Paris’ Seine River, the project secured approval for its first real-world bridge in France. Slated for 2025, the installation will undergo rigorous environmental and structural monitoring. Beyond bridges, the team is exploring prefabricated floor systems—hinting at broader architectural applications.

As cement industry initiatives struggle to offset rising demand-driven emissions, Diamanti exemplifies how computational design and biomimicry could transform one of civilization’s oldest materials. By rethinking both what concrete contains and how it’s formed, Akbarzadeh’s lab might just have poured the foundation for construction’s low-carbon future.

Source: CNN Science

Comments

Please log in or register to join the discussion