Researchers at Politecnico di Milano have developed LokAlp, a reconfigurable timber construction system using off-cuts from CLT and GLT production. By combining computational design, robotic milling (showing >45% faster production than CNC), and augmented reality-guided assembly, this system enables waste-free, self-built structures while maintaining Eurocode compliance. The patented approach demonstrates how industrial by-products can achieve architectural-scale buildings through discrete, reus

Turning Timber Waste into Architectural Innovation

Every year, the cross-laminated timber (CLT) industry generates staggering waste volumes—up to 20% of panel production becomes off-cuts from window/door openings, while glued laminated timber (GLT) distribution leaves mountains of sub-4-meter remnants. Traditionally downcycled or incinerated, these high-strength engineered wood scraps represent both an environmental liability and untapped potential. Enter LokAlp: a patented construction system transforming this waste stream into reconfigurable building blocks through computational design and digital fabrication.

The Blockbau Reimagined for the Circular Economy

Developed at Politecnico di Milano's INDEXLAB, LokAlp draws inspiration from traditional European Blockbau techniques—where timber structures were disassembled and rebuilt centuries later—but reengineered for industrial scalability. The system’s core innovation lies in its standardized, asymmetrical blocks (Type A: 960mm, Type B: 480mm lengths) and nine connector types (“biscuits”), enabling dry-assembled walls, beams, and columns without adhesives.

"Unlike lightweight timber systems dominating computational architecture, LokAlp prioritizes material mass and continuity," explains co-inventor Matteo Deval. "We’re proving discrete components can form airtight, load-bearing enclosures for ordinary buildings—not just pavilions."

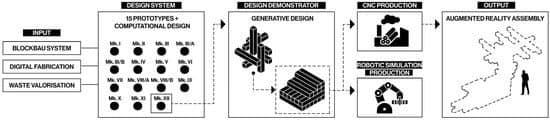

Digital Workflow: From Waste to Structure

Computational Optimization: Grasshopper3D scripts parametrically adapt block geometry to available off-cut dimensions and tooling constraints (e.g., dovetail cutter profiles), minimizing material waste (21.8-30.1% in tested iterations).

Robotic Fabrication Breakthrough: Simulations using an ABB IRB 4600 robotic arm demonstrated a 22-minute per-block cycle time—over 45% faster than conventional Hundegger K2i CNC centers (40 mins/block). The robotic cell’s inclined centering plane enabled automatic repositioning for 6-axis milling of all faces without manual intervention.

# Simplified robotic workflow pseudocode

def fabricate_block(raw_glt):

robot.grip(raw_glt)

position_on_centering_plane()

for face in range(6):

mill_dovetail_joints(face)

if face < 5:

reposition_on_plane(rotate=90°)

place_in_output_stack()

- AR-Guided Self-Build: Assembling the 120-block, 237-connector demonstrator leveraged HoloLens 2 and Fologram, projecting real-time holograms onto the construction site. This eliminated traditional 2D plans, reducing cognitive load and orientation errors during the 367-step process. A single operator completed assembly in two 8-hour shifts—even for cantilevered sections on scaffolding.

Industrial Implications and Future Challenges

The Mk.XII prototype advances prior iterations with 44 possible connections per block and cubic-matrix compliance. However, hurdles remain:

- Structural Validation: While CLT/GLT off-cuts retain original mechanical properties, joint performance under dynamic loads requires rigorous testing.

- Robotic Scalability: Real-world validation of simulated 45% production gains must account for thermal management and tolerance stacking.

- Waste-Positive Strategy: Integrating selective milling (only essential faces) could slash waste to 14%, enhancing economic viability.

As timber construction grapples with embodied carbon, LokAlp’s closed-loop approach—where buildings become material banks for future structures—signals a shift toward genuinely circular architecture. With its EUIPO-registered design now public, the system invites collaboration to tackle scaling and certification barriers.

Source: Deval, M.; Ruttico, P. LokAlp: A Reconfigurable Massive Wood Construction System Based on Off-Cuts from the CLT and GLT Industry. Sustainability 2025, 17, 6002. https://doi.org/10.3390/su17136002

Comments

Please log in or register to join the discussion