NASA is testing a revolutionary two-stage cooling system to prevent cryogenic propellant loss in space, tackling a major hurdle for long-duration missions to the Moon and Mars. The 'tube on tank' technique could eliminate fuel boiloff by intercepting heat before it reaches storage tanks, enabling sustainable exploration. This innovation marks a critical leap in cryogenic fluid management, essential for future crewed interplanetary travel.

In the vacuum of space—where temperatures plunge to -455°F—keeping cryogenic propellants like liquid hydrogen and liquid oxygen from boiling off might seem straightforward. Yet, paradoxically, space acts as an insulator, trapping heat from spacecraft systems, solar radiation, and engine exhaust that causes these supercold fuels to vaporize. This boiloff forces missions to carry excessive fuel margins or vent precious propellant, a deal-breaker for ambitious journeys to Mars or extended lunar operations.

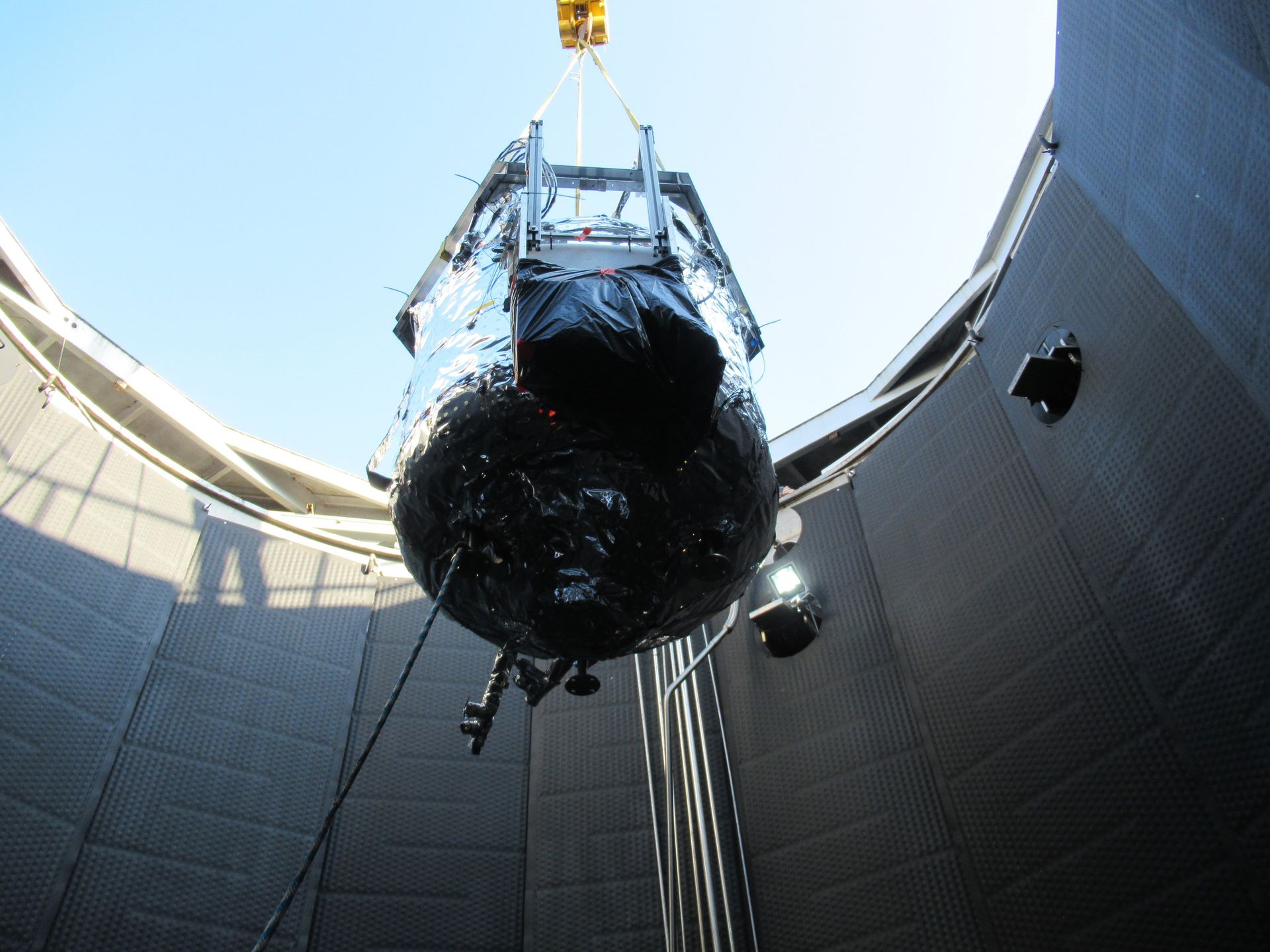

The propellant tank for NASA’s two-stage cooling tests is lowered into a vacuum chamber at Marshall Space Flight Center. (Credit: NASA/Kathy Henkel)

Now, NASA’s Cryogenic Fluid Management team has engineered an elegant solution: a two-stage active cooling system dubbed "tube on tank." Here’s how it works:

- Stage 1: Helium chilled to -424°F circulates through tubes welded to the tank’s exterior, directly cooling the stored liquid hydrogen.

- Stage 2: A secondary helium loop at -298°F runs through a heat shield layered within the tank’s insulation, intercepting external heat before it penetrates the primary system.

This dual approach achieves near zero boiloff, a first for large-scale cryogenic storage. As Kathy Henkel, acting manager of NASA’s Cryogenic Fluid Management project, explains:

"To go to Mars and have a sustainable presence, you need to preserve cryogens for use as rocket or lander return propellant. Two-stage cooling prevents propellant loss and allows for long-term storage whether in transit or on planetary surfaces."

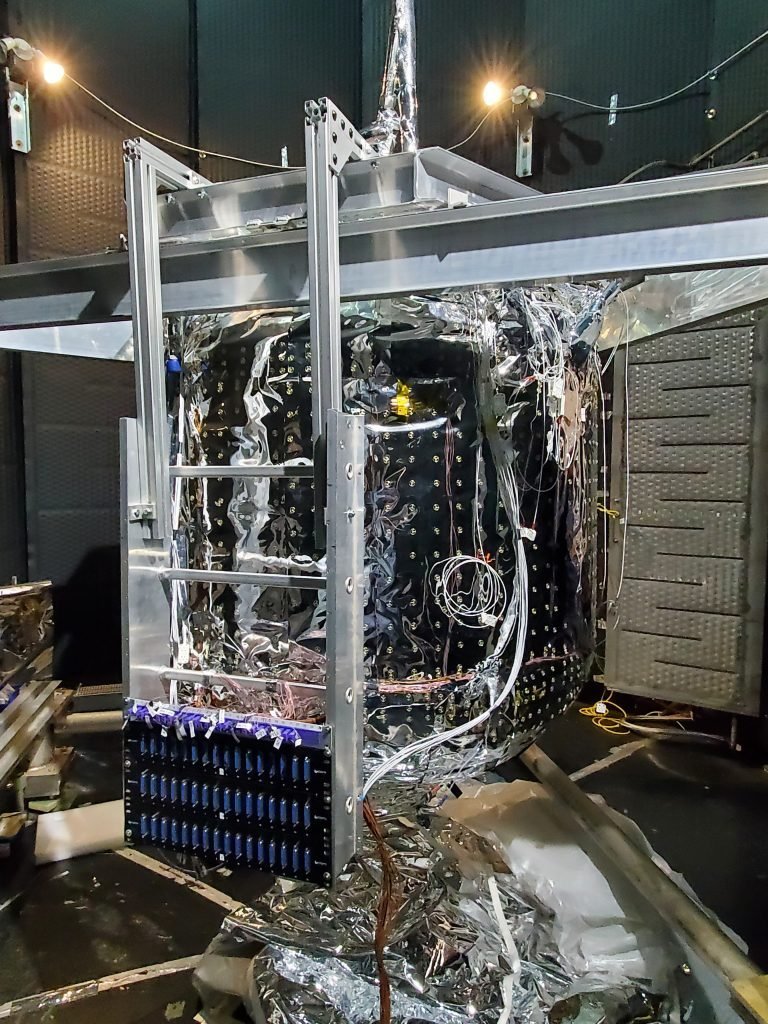

Testing setup inside a vacuum chamber simulates space conditions at Marshall Space Flight Center. (Credit: NASA/Tom Perrin)

Currently in a 90-day test campaign at Marshall Space Flight Center, the technology addresses a glaring gap. Existing systems limit cryogenic missions to under a week due to boiloff, but Mars missions require fuel stability for years. The innovation slashes the need for oversized tanks—currently used to compensate for losses—freeing up mass for scientific payloads or life-support systems.

Beyond propulsion, this breakthrough has ripple effects for in-situ resource utilization (ISRU). Storing lunar or Martian water-derived propellants becomes feasible, enabling refueling depots that cut Earth-launch costs. Funded under NASA’s Technology Demonstration Missions Program, the project underscores how cryogenic fluid management is no longer optional but foundational for humanity’s interplanetary future. As tests progress toward September, success here could finally turn multi-year missions from concept to reality.

Source: NASA's Cryogenic Fluid Management Team, Marshall Space Flight Center.

Comments

Please log in or register to join the discussion