A 16‑year‑old student turned a LEGO Mindstorms kit into a functional replica of the SoftHand‑A robotic hand, proving that complex biomechanical concepts can be taught through play. The project not only matches the performance of the original 3D‑printed design but also opens doors for low‑cost, hands‑on robotics education.

A LEGO Hand That Can Grasp Like a Real One

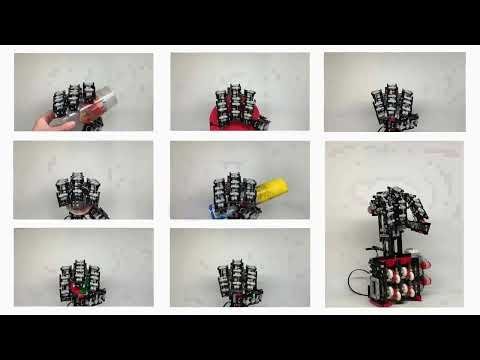

In a striking demonstration at the 2025 IEEE/RSJ International Conference on Intelligent Robots and Systems in Hangzhou, a 16‑year‑old named Jared Lepora unveiled a robotic hand built entirely from LEGO bricks. The hand is a faithful recreation of the SoftHand‑A, a state‑of‑the‑art anthropomorphic gripper originally 3D‑printed and used in research labs worldwide.

“My goal was to create an educational design which shows professional mechanisms in a simple educational way understandable by children.” – Jared Lepora, presenter.

From Blueprints to Bricks

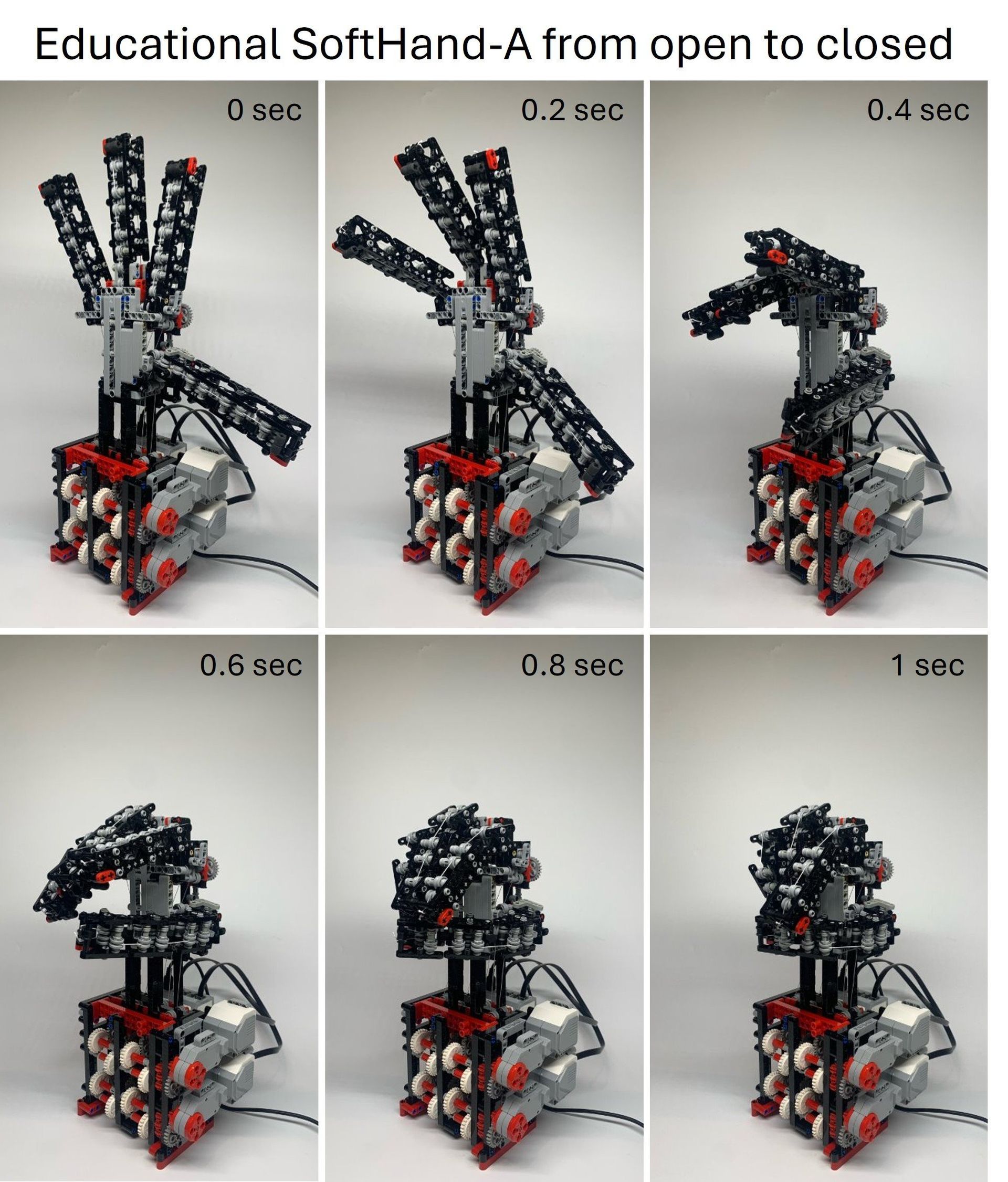

Jared began by digitally modeling the hand, which incorporates two motors, four fingers, and two tendons per finger. The real challenge lay in routing the tendons around rotating bearings so the finger joints could flex and extend. The LEGO version uses over 100 bearings—a feat that required meticulous planning to keep the hand lightweight and functional.

The team, which includes Jared’s father, Nathan Lepora, a professor at the University of Bristol’s Robotics Laboratory, documented the design process and performance tests on arXiv.

Performance Meets Play

In comparative tests, the LEGO SoftHand‑A matched the original 3D‑printed hand in response time, bearing capacity, pushing capacity, and closing force—only slightly behind in speed and force but within a statistically insignificant margin. This demonstrates that LEGO, traditionally viewed as a toy, can serve as a legitimate platform for prototyping sophisticated robotic mechanisms.

“Building a robot hand with your own hands is a great way to learn about robotics.” – Jared

Implications for Education and Innovation

- Democratizing Robotics – The project shows that high‑quality robotic components can be assembled from inexpensive, widely available LEGO bricks, lowering the barrier to entry for schools and hobbyists.

- Hands‑On Learning – By translating complex biomechanical concepts into a tangible, buildable model, students gain intuitive understanding of tendon‑driven actuation and joint mechanics.

- Rapid Prototyping – Engineers can quickly iterate designs using LEGO, testing kinematic concepts before committing to costly 3D‑printing or machining.

- Cross‑Disciplinary Inspiration – The intersection of mechanical design, control theory, and playful construction sparks interest across STEM fields.

The project also hints at a broader trend: the use of modular, consumer‑grade hardware to explore advanced robotics concepts, potentially accelerating the pace of innovation.

A Call to the Next Generation

Jared’s words echo a growing sentiment in the robotics community: “My generation—and younger—are the future of robotics.” By turning a LEGO kit into a functional research tool, he demonstrates that curiosity and creativity can bridge the gap between play and professional engineering.

Source: Popular Science article "Teen builds robotic hand out of legos", arXiv preprint by Jared Lepora et al.

Comments

Please log in or register to join the discussion