Airbus soared to dominance not just through engineering excellence but by mastering a relentless customer focus and rejecting European industrial chauvinism, while Boeing's shift from an engineering-first ethos to a 'run like a business' philosophy culminated in costly disasters. This deep dive explores the technical innovations, industrial policy gambits, and corporate cultures defining the high-stakes battle for the skies.

The terrifying mid-air blowout on Alaska Airlines Flight 1282 in January 2024 – where a door plug ripped away at 16,000 feet due to missing critical bolts – wasn't just another aviation incident. It was the latest symptom of a deep-seated crisis at Boeing, starkly contrasting the relative stability of its European rival, Airbus. This divergence isn't merely corporate; it's rooted in fundamentally different approaches to engineering, safety culture, and the very purpose of building aircraft – a clash with profound lessons for technology leaders across industries.

From Fragmented Failure to Global Leader: Airbus's Unlikely Ascent

European aerospace in the 1960s was a fragmented graveyard of failing national champions, decimated by the dominance of US giants like Boeing, fueled by massive military contracts and protected markets like the Buy America Act. Designs like the Boeing B-47 bomber directly influenced commercial jets, creating an insurmountable advantage. Facing oblivion, European governments gambled on cooperation, forming the Airbus consortium in 1970.

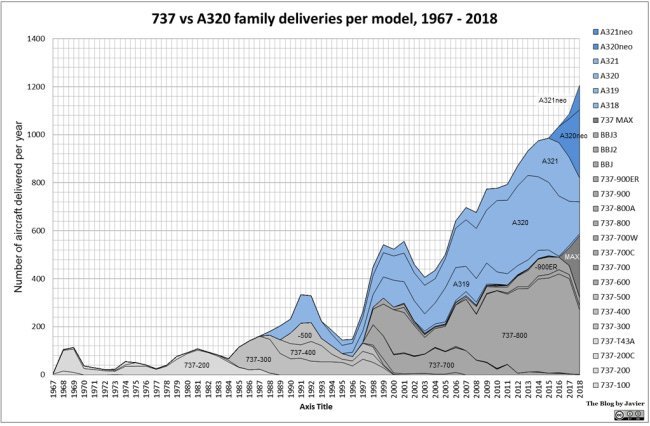

Boeing 737 and Airbus A320 family deliveries over time. (Javier Irastorza via Wikimedia)

Boeing 737 and Airbus A320 family deliveries over time. (Javier Irastorza via Wikimedia)

Airbus's success defied the typical European industrial policy playbook. Unlike vanity projects like Concorde or doomed committees like Unidata (a failed European mainframe consortium), Airbus succeeded through:

- Relentless Customer Obsession: Led by Roger Béteille, the A300 program tossed initial designs after deep engagement with airlines like Air France and Lufthansa, leading to a smaller, cheaper, fuel-efficient twin-engine wide-body – a radical departure from the tri-jet norm. This pragmatism extended to choosing cheaper American engines, even at the cost of UK partners temporarily leaving.

- Centralized Leadership & Pragmatism: Béteille and production director Felix Kracht imposed English as the working language, mandated imperial measurements for the US market, and established a clear, optimized division of labor across European partners. National pride took a backseat to efficiency and market needs.

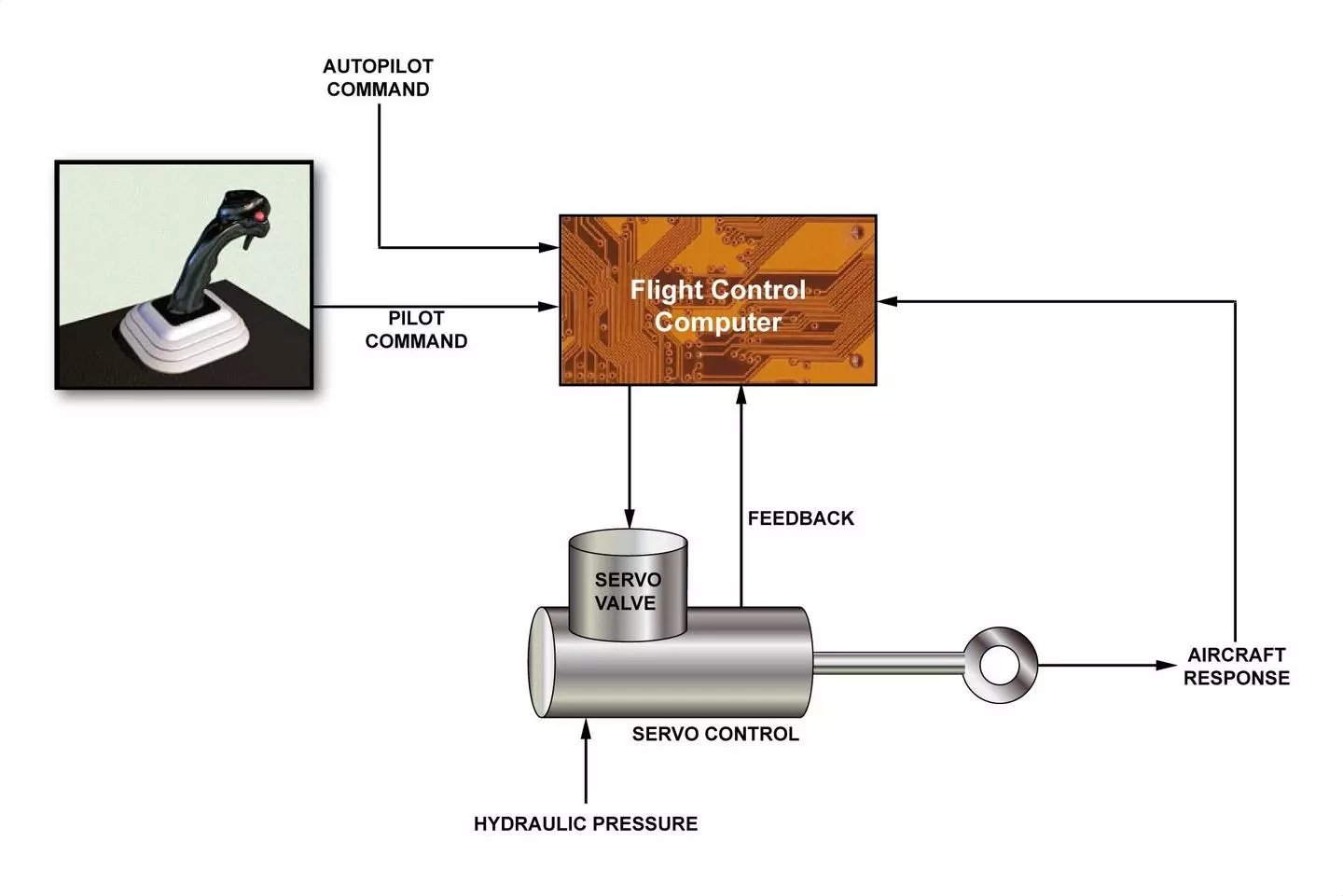

- Bold Technical Innovation: The A300 pioneered composite materials for weight savings. Its successor, the landmark A320, introduced revolutionary digital fly-by-wire controls and envelope protection systems, replacing heavy mechanical linkages with computer-controlled actuators and preventing pilots from exceeding safe flight parameters.

A digital fly-by-wire system. (Airbus)

A digital fly-by-wire system. (Airbus)

- Ruthless Market Strategy: Facing US skepticism, Airbus downplayed its European roots, emphasized high US component content, and mastered DC lobbying. Its audacious move to lease jets to Eastern Airlines for $1 proved a masterstroke in gaining US market credibility.

Boeing's Fatal Shift: From Engineering Firm to "Business"

While Airbus cultivated its engineering-led, customer-focused culture, Boeing underwent a seismic shift. The 1997 acquisition of McDonnell Douglas, often described as a reverse takeover culturally, marked a turning point. Leadership, transplanted to Chicago away from its Seattle engineering heart, explicitly rejected its heritage. CEO Harry Stonecipher declared the intent to change Boeing's culture to run "like a business rather than a great engineering firm." Successor James McNerney dismissed ambitious "moonshots," prioritizing shareholder returns over groundbreaking innovation.

This cultural decay manifested technically. The 737 MAX, developed under intense cost and time pressure to compete with Airbus's A320neo, relied on the flawed Maneuvering Characteristics Augmentation System (MCAS). Crucially:

- Single Point of Failure: MCAS could activate based on input from a single Angle of Attack (AoA) sensor.

- Inadequate Disclosure & Training: Pilots weren't fully informed about MCAS's capabilities or behavior, leaving them unprepared for malfunctions.

- Lack of Redundancy: The system lacked robust failsafes.

The result was two catastrophic crashes in 2018 and 2019, killing 346 people, followed by the Alaska Airlines door plug incident – stark evidence of systemic quality control and supplier management failures. Regulatory scrutiny, lawsuits, and a shattered reputation became Boeing's reality.

Lessons Beyond the Runway: Why Industrial Strategy (Mostly) Fails

Airbus stands as a rare industrial policy success, but its victory underscores why replicating it is extraordinarily difficult:

- Industry Structure Matters: Commercial aviation is uniquely brutal. Airlines operate on razor-thin margins, are perpetually near bankruptcy (Buffett famously wished the Wright brothers' plane had been shot down), and exert massive downward price pressure on manufacturers. The decade-long, multi-billion-dollar development cycles are almost impossible without state backing (subsidies for Airbus, military contracts for Boeing).

- Execution is Everything: Success required Airbus's unique blend of centralized leadership, customer obsession, technical courage (fly-by-wire), and willingness to defy political pressures for national favoritism. Projects like Concorde (technologically brilliant, economically doomed), Unidata (paralyzed by committee), or Quaero (a directionless 'European Google') failed precisely where Airbus excelled.

- Culture Eats Strategy: The stark contrast between Airbus's enduring engineering focus and Boeing's shift towards financial engineering and cost-cutting is the core narrative. In safety-critical, complex technological domains, prioritizing quarterly returns over systemic engineering rigor and robust safety cultures is a recipe for disaster.

The Airbus-Boeing saga is more than an aviation story; it's a masterclass in how technology, corporate culture, and industrial policy intersect. For engineers and tech leaders, it underscores that building complex, reliable systems demands unwavering commitment to technical excellence, deep user understanding, and a culture that prioritizes the integrity of the product above all else. When those principles erode, the consequences, as recent tragedies show, can be catastrophic. Boeing's path back requires not just fixing bolts and software, but rediscovering the soul of an engineering company.

Comments

Please log in or register to join the discussion