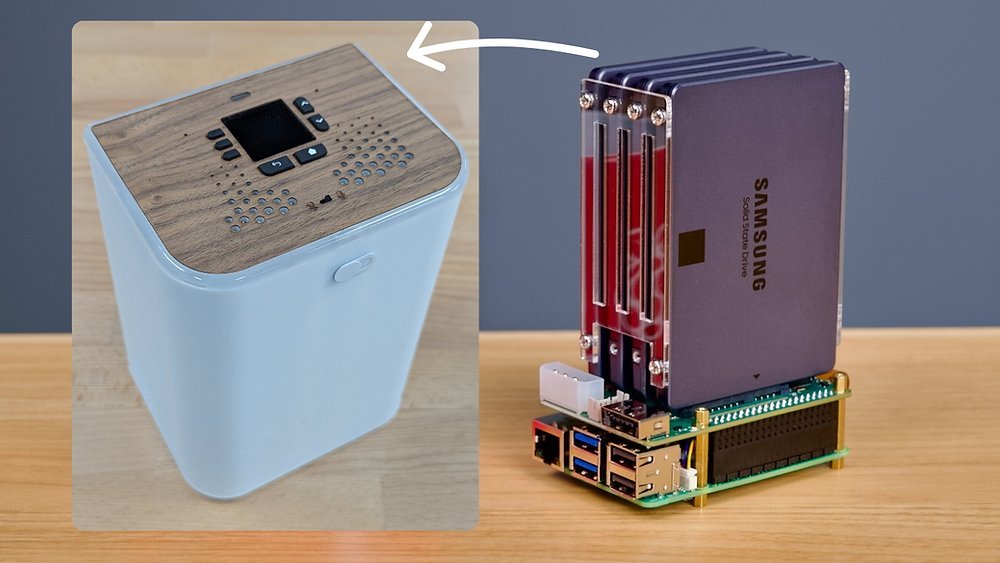

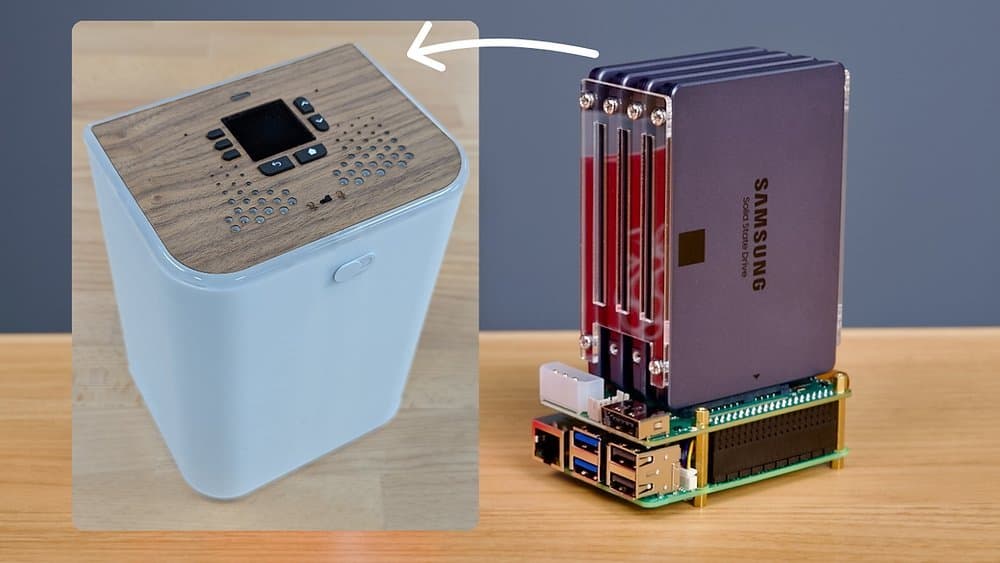

A new open-source NAS project combines Raspberry Pi 5 with Radxa's Penta SATA HAT in a custom aluminum enclosure featuring an embedded GUI for direct system monitoring and file management. The design adds USB-PD power delivery and future UPS support while sharing 3D models and PCB designs for community collaboration. This approach rethinks DIY storage by integrating physical hardware refinement with accessible software controls.

The DIY NAS movement gains sophistication with an ambitious new project merging Raspberry Pi 5's processing power, Radxa's high-density storage capabilities, and professional-grade aluminum housing. Inspired by Jeff Geerling's compact Pi 5 NAS experiments, this build introduces three innovations that elevate the DIY storage concept: a thermally efficient CNC-milled enclosure, an embedded touchscreen GUI for direct system interaction, and a custom USB-PD power board enabling cleaner 12V power delivery—with future plans for integrated UPS functionality.

Hardware Synergy: Pi 5 + Radxa Penta HAT

At its core, the system pairs Raspberry Pi 5 (4GB minimum) with Radxa's Penta SATA HAT, enabling five-drive connectivity in a footprint smaller than traditional NAS enclosures. This foundation leverages OpenMediaVault or Immich for storage and media management, but diverges through physical refinements:

- Aluminum Enclosure: Designed around extruded profiles similar to the creator's Ubo Pod project, it prioritizes heat dissipation and structural rigidity over 3D-printed prototypes

- Embedded GUI: A touchscreen interface displays real-time CPU/memory/network metrics and allows basic file operations—like previewing images—without external peripherals

- Power Innovations: The custom side-board replaces barrel connectors with USB-PD input while prototyping future UPS support for internal battery backups

From Prototype to Production

Current iterations use 3D-printed components, but production units will employ CNC-machined aluminum. The GUI software builds upon the open-source Ubo-app framework, with disk monitoring features actively being implemented. Community feedback directly shapes development—design files (STLs, KiCAD schematics) are available on GitHub, while early adopter kits are offered via Shopify.

Initial 3D-printed prototype showcasing component layout and GUI integration

Initial 3D-printed prototype showcasing component layout and GUI integration

Why This Matters for DIY Culture

This project exemplifies hardware hacking's evolution: It addresses pain points in existing solutions (cable clutter, external monitoring dependencies) while maintaining accessibility. The USB-PD board alone eliminates dedicated power bricks, and the GUI enables "headless" file transfers via USB drives. By open-sourcing mechanical and electrical designs, the creator invites collaborative refinement—a model that accelerates innovation beyond proprietary ecosystems.

As Raspberry Pi 5 unlocks new embedded potential, projects like this demonstrate how thoughtful integration layers—physical and digital—can transform commodity hardware into elegant, user-centric solutions. The full build documentation and video series are available on GitHub and the Ubo blog.

Comments

Please log in or register to join the discussion