Chinese modder Geekerwan achieves world-class overclocking results with AMD's flagship workstation CPU using custom CNC-machined IHS, automotive pumps, and industrial chiller in a 37-gallon setup.

Chinese hardware enthusiast Geekerwan has pushed AMD's $12,000 Ryzen Threadripper Pro 9995WX to extraordinary limits with a custom 2,000W direct die cooling solution that combines automotive-grade components, industrial chillers, and precision CNC machining.

The project began with extensive preparation work on AMD's flagship 96-core Zen 5 processor. Rather than risking the expensive CPU itself, Geekerwan borrowed an IHS (integrated heat spreader) from Tony Yu, General Manager of Asus China, and conducted experiments on several sacrificed Ryzen Threadripper 1900X processors to perfect the cooling design.

The cooling solution features several groundbreaking innovations:

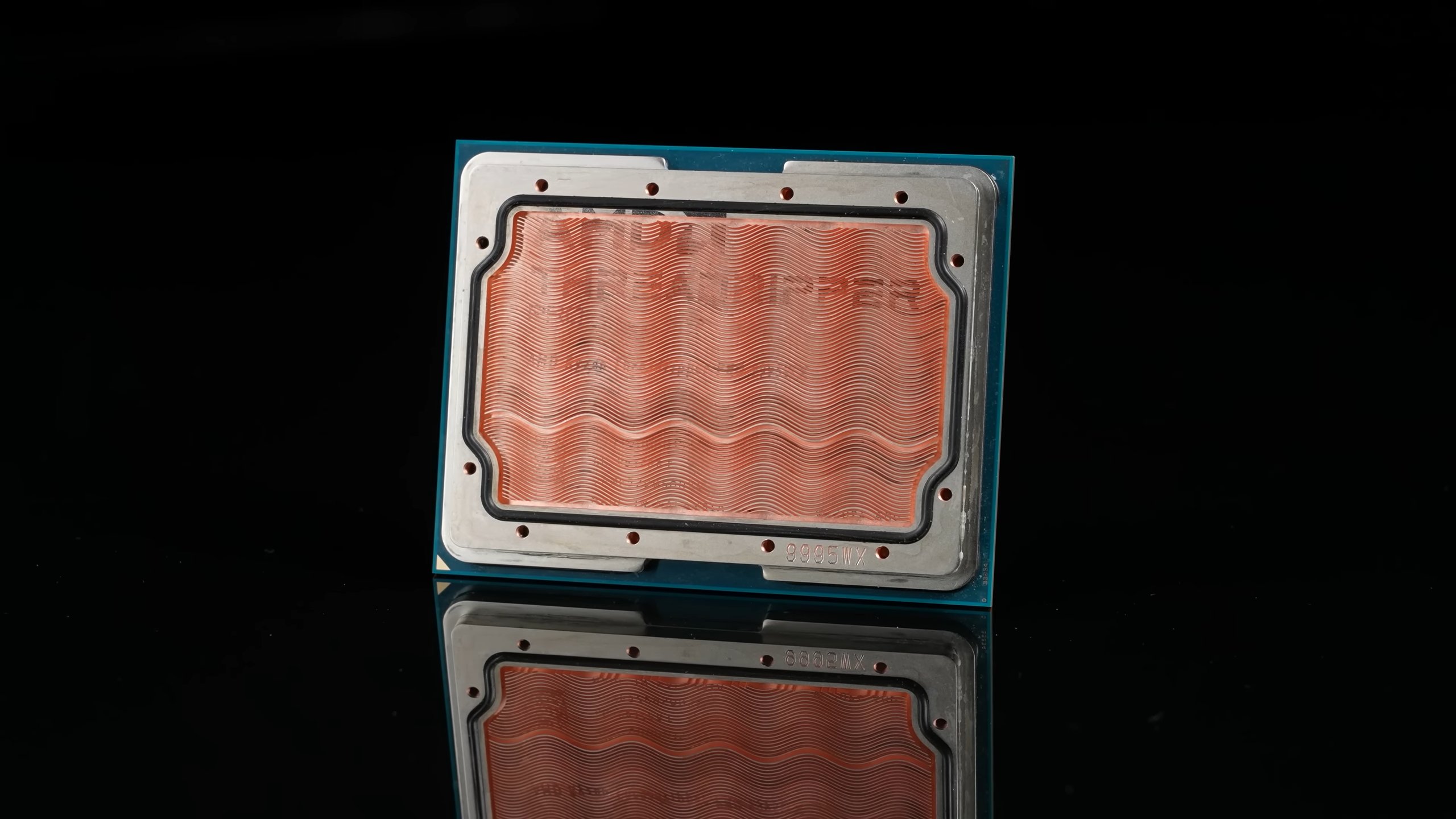

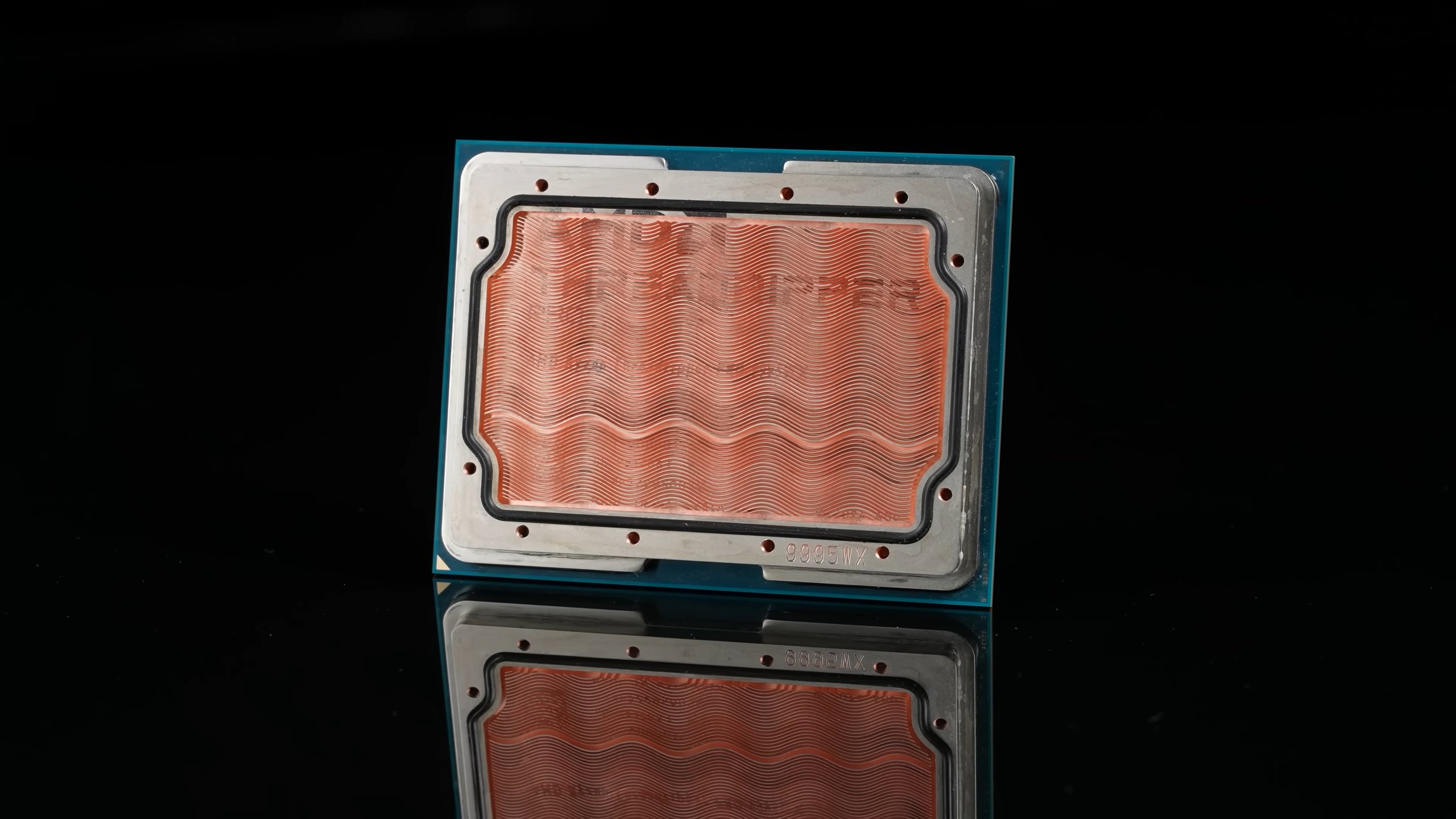

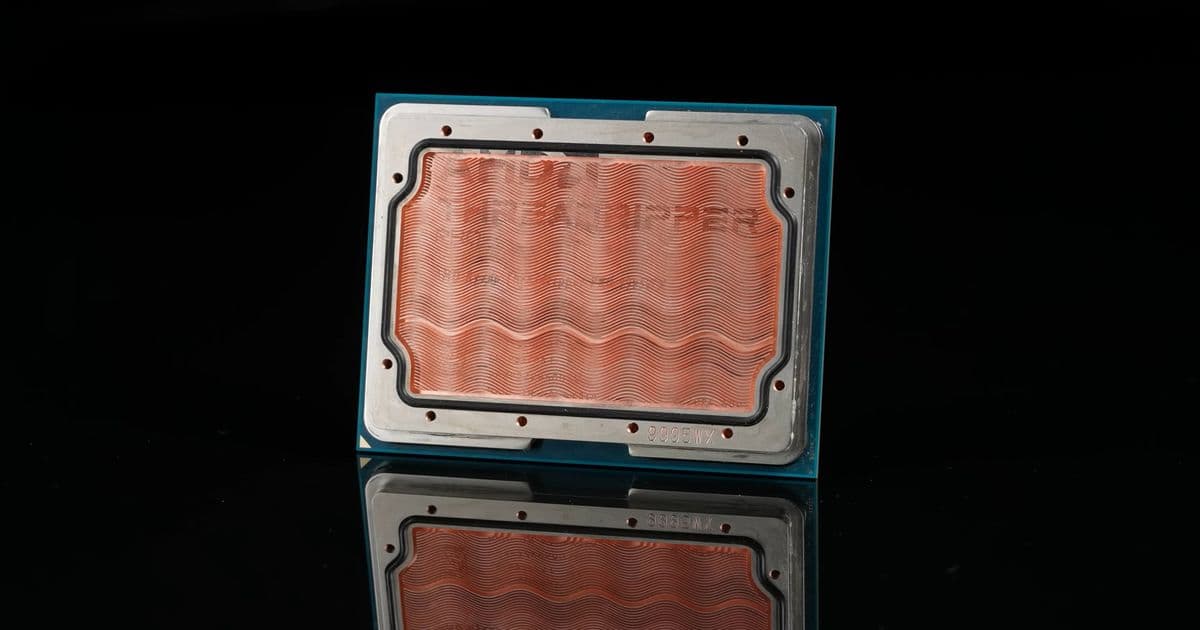

Custom CNC-Machined IHS

- Ultra-thin 0.15mm cooling fins with 0.3mm spacing

- Wavy S-shaped microchannels (20% more heat dissipation area than straight channels)

- 2.0mm depth cut to balance cooling performance and structural integrity

- 19 hours of machining time using Taikan T-700S CNC machine

- 14 cutting tools destroyed during the process

The wavy microchannel design proved particularly effective, showing up to 1.2°C improvement over traditional straight channels in testing. The deeper 2.0mm cuts provided optimal cooling while maintaining sufficient structural strength to prevent deformation under water pressure.

Innovative Water Block Design Unlike conventional dual-tube designs, Geekerwan developed a four-tube cross-pattern configuration specifically for the Threadripper Pro's unique chiplet layout. The two central CCDs sit at the chip's far edges, requiring careful consideration of coolant flow patterns.

- Three-tube prototype testing showed up to 5.1°C temperature reduction

- Final four-tube design with two central inlets and two side outlets

- Optimized for equal heat dissipation across both CCDs

Automotive-Grade Components

- Two 50W Bosch water pumps (one from Mercedes, one from Geely)

- Industrial chiller cooling liquid to 0°C

- 37-gallon water reservoir

- Total system power draw: 1,700W+

The industrial chiller and massive reservoir ensure stable temperatures even under extreme loads, with coolant maintaining around 2°C during operation.

Overclocking Results Geekerwan achieved remarkable performance figures:

| Frequency | 5.325 GHz | 5.2 GHz | 4.7 GHz |

|---|---|---|---|

| System Power | 1,634W | 1,552W | 951W |

| Cinebench R23 | 205,332 | 194,300 | 174,137 |

| Cinebench 2024 | 10,080 | N/A | N/A |

| Cinebench 2026 | 41,478 | N/A | N/A |

The overclocked Threadripper Pro 9995WX delivered up to 18% higher multi-core performance compared to stock PBO settings. At 5.3 GHz with approximately 1,340W power consumption, core temperatures stayed between 30°C and 50°C, with the entire system idling at just 5°C.

Benchmark Rankings

- Cinebench R23: 7th place globally (trailing only liquid nitrogen-cooled systems)

- Cinebench 2024: 3rd place

- Cinebench 2026: 2nd place

These results demonstrate that extreme cooling solutions don't always require exotic cooling methods like liquid helium or hydrogen. The project showcases how engineering ingenuity and automotive-grade components can achieve world-class performance.

For enthusiasts without access to industrial chillers and CNC machines, the industry is moving toward high-power AIO solutions. Cooler Master recently announced its 360² cooler, claiming to dissipate up to 2,000W of heat with its massive 360 x 360mm radiator.

This achievement represents a significant milestone in enthusiast cooling, proving that with enough creativity and technical expertise, even the most extreme cooling challenges can be overcome using accessible components and innovative design approaches.

Comments

Please log in or register to join the discussion