Researchers at Tsinghua University have developed a revolutionary 3D printing method that can produce complex millimeter-scale objects in just 0.6 seconds using holographic light fields.

Chinese scientists have achieved a remarkable breakthrough in additive manufacturing that could revolutionize how we produce tiny, complex components. A research team from Tsinghua University has developed a new technique called Digital Incoherent Synthesis of Holographic light fields (DISH) that can 3D print millimeter-scale objects in just 0.6 seconds, according to a paper published in Nature earlier this week.

Traditional 3D printing methods typically require anywhere from tens of minutes to hours to produce complex, detailed shapes. This makes them impractical for many applications that require rapid prototyping or mass production of small components. The DISH technology addresses this limitation by fundamentally changing how light interacts with photosensitive materials during the printing process.

How DISH Technology Works

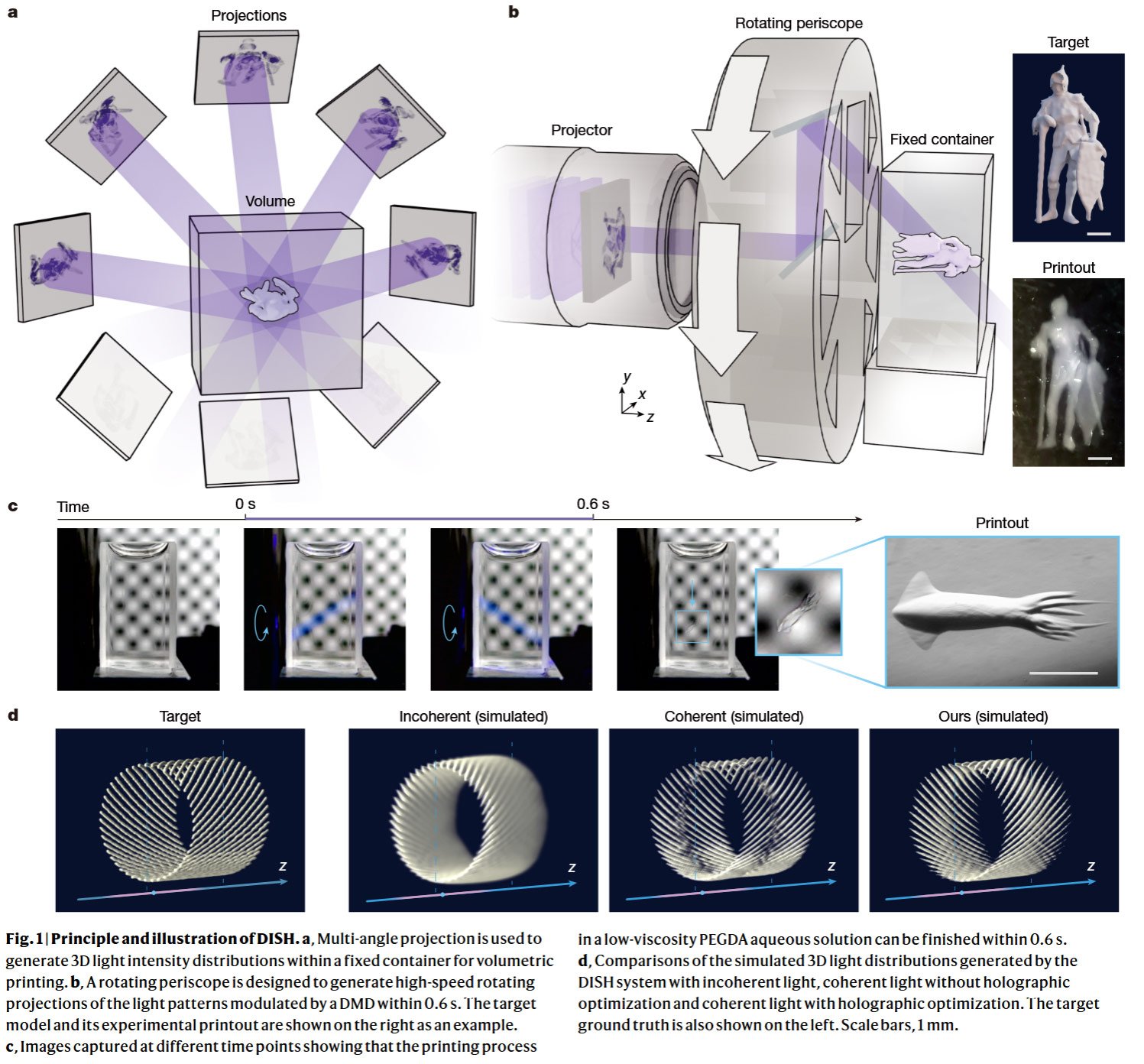

The key innovation behind DISH lies in its approach to light projection. Traditional volumetric additive manufacturing cures high-viscosity resins by projecting patterned light through the material as the object rotates 360 degrees on a pedestal. This rotation-based method, while effective, inherently limits the speed at which objects can be produced.

DISH takes a different approach by keeping the material stationary and instead rotating a high-speed multi-perspective light field around it. This enables the precise projection of complex 3D light intensity distributions in an extremely short time. The technology leverages computational optics to control light from multiple angles simultaneously, creating intricate patterns that cure the resin in specific locations to form the desired 3D shape.

Speed and Precision Advantages

The stationary material approach offers several advantages beyond just speed. The researchers claim that DISH provides improved stability and accuracy compared to traditional rotating methods. By eliminating the mechanical movement of the object being printed, there's less potential for vibration or misalignment that could compromise the final product's precision.

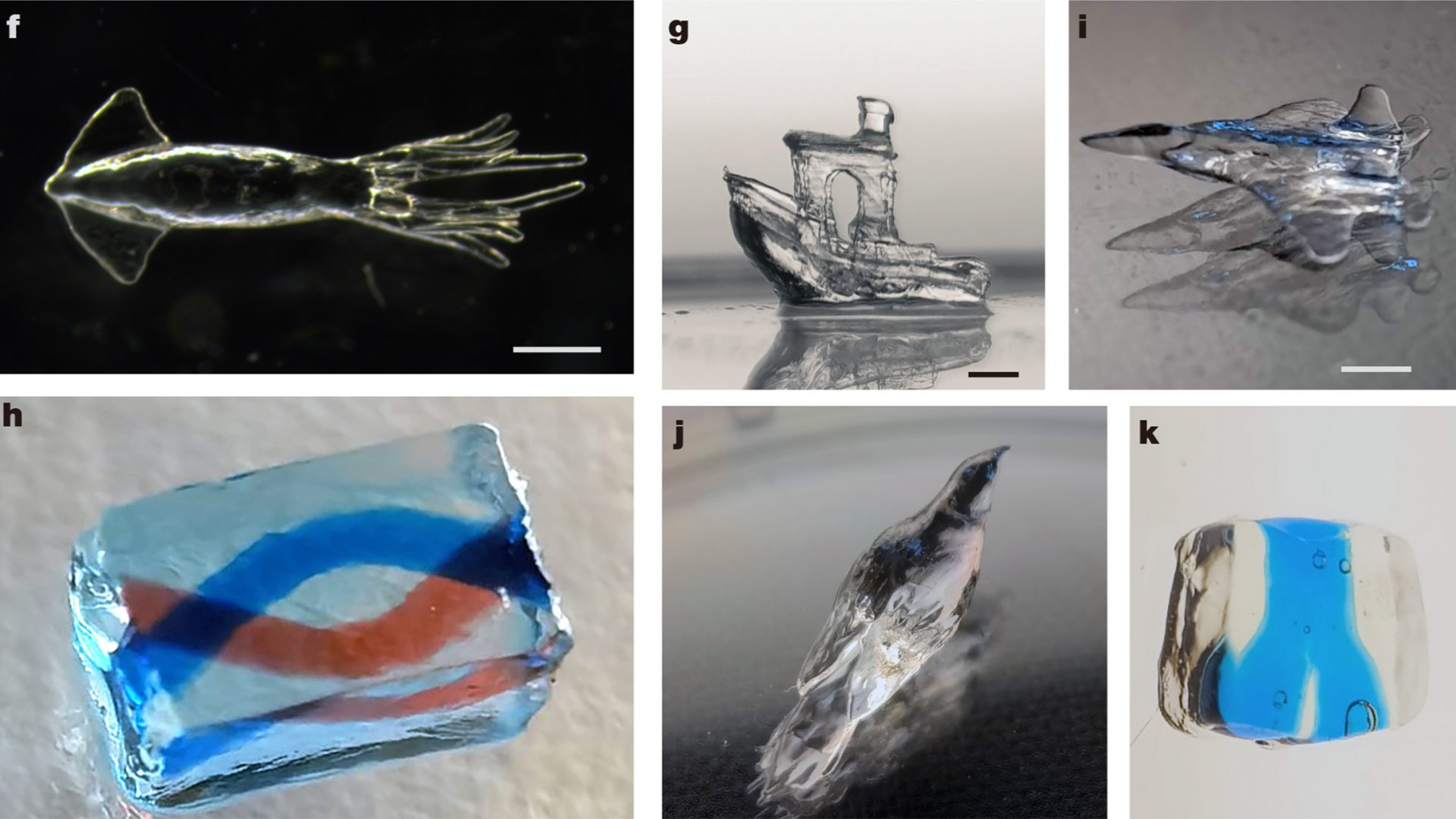

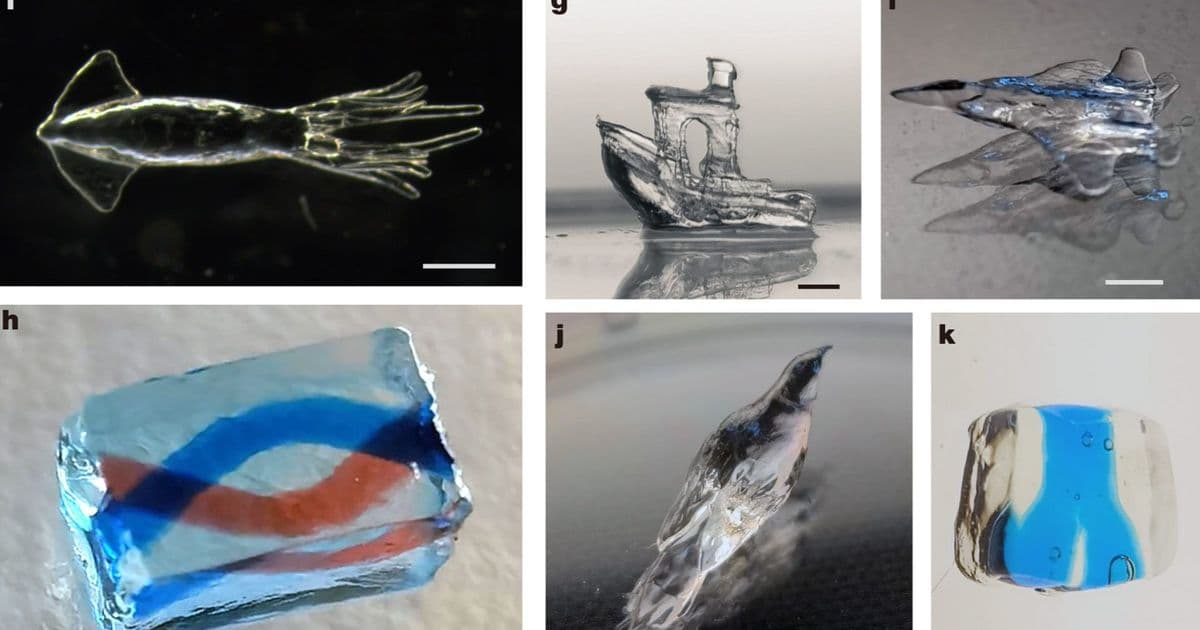

This combination of speed and accuracy makes DISH particularly well-suited for applications requiring micrometer-scale precision. The technology can produce complex geometries with sharp angles and curved surfaces that would be challenging or impossible to achieve with conventional 3D printing methods.

Potential Applications

The Chinese scientists envision numerous applications for DISH technology across various industries. They specifically highlight its potential for producing micro-components such as photonic computing devices and mobile phone camera modules. These applications require extremely precise manufacturing at small scales, making the speed and accuracy of DISH particularly valuable.

Beyond consumer electronics, the researchers see potential in flexible electronics manufacturing, where complex, curved components need to be produced quickly and accurately. The technology could also revolutionize micro-robotics by enabling rapid prototyping and production of tiny mechanical parts with intricate geometries.

Perhaps most intriguingly, the team suggests that DISH could be applied to high-resolution tissue engineering. This could have significant implications for medical research and potentially even regenerative medicine, where precise, biocompatible structures need to be created quickly.

Mass Production Potential

While the current demonstrations focus on millimeter-scale objects, the researchers are already discussing the technology's potential for mass production. The ability to produce complex components in fractions of a second could dramatically reduce manufacturing costs and lead times for products that currently require expensive, time-consuming production processes.

This scalability is particularly important for industries like consumer electronics, where millions of identical micro-components need to be produced efficiently. The combination of speed, precision, and potential for automation makes DISH an attractive option for manufacturers looking to optimize their production processes.

Technical Challenges and Future Development

Despite the promising results, several technical challenges remain before DISH can be widely adopted. The technology requires sophisticated computational optics systems and precise control of light fields, which may initially limit its accessibility to well-funded research institutions and large manufacturers.

Additionally, while the speed advantages are clear for small objects, scaling the technology to produce larger components while maintaining the same level of precision and speed will require further research and development. The team will need to address issues related to light penetration depth, resin properties, and heat management as they work to expand the technology's capabilities.

Industry Impact

The development of DISH technology represents a significant milestone in additive manufacturing. By dramatically reducing production times while improving precision, it could help bridge the gap between prototyping and mass production that has traditionally limited 3D printing's industrial applications.

For industries that rely on small, complex components—such as aerospace, medical devices, and consumer electronics—this technology could enable new design possibilities and manufacturing efficiencies. The ability to quickly produce prototypes and iterate designs could accelerate innovation cycles across multiple sectors.

As the technology matures and becomes more accessible, we may see a shift in how manufacturers approach small-scale production. Rather than relying on traditional injection molding or machining for complex micro-components, companies might adopt DISH-based systems that offer greater design flexibility and faster turnaround times.

The research from Tsinghua University demonstrates how advances in computational optics and materials science can combine to create transformative manufacturing technologies. As the team continues to refine DISH and explore its applications, we may be witnessing the early stages of a new era in precision manufacturing that could impact everything from our smartphones to medical treatments.

Comments

Please log in or register to join the discussion