MIT CSAIL researchers have developed MechStyle, a generative AI tool that personalizes 3D models while ensuring they remain structurally sound for real-world use, addressing a critical gap where aesthetic modifications often compromised durability.

The promise of generative AI has largely lived in the digital realm, creating stunning images, videos, and text. When it comes to the physical world, however, the technology faces a fundamental barrier: the laws of physics. Generative models can easily modify a 3D model to look like a cactus or a lava lamp, but they have no inherent understanding that turning a wall hook into a spiky plant might make it snap under the weight of a backpack.

This gap between digital creativity and physical reality is what MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) researchers, led by PhD student Faraz Faruqi, aim to bridge with MechStyle. The system integrates generative AI with mechanical simulation, allowing users to create personalized, durable 3D-printed objects without sacrificing structural integrity.

The Problem with Pure Generative 3D

When you ask a standard AI image generator to "make this vase look like it's made of molten lava," it happily complies by altering the pixel data. When you ask a 3D generative system to do the same, it modifies the mesh geometry. The result might look exactly as requested, but the physical properties can be disastrous.

Faruqi's initial research revealed the scope of this problem. In a formative study, his team found that only about 26% of 3D models remained structurally viable after AI-driven aesthetic modifications. The AI simply didn't understand that removing material from a load-bearing column or creating thin, decorative spikes could render the object unusable.

"We want to use AI to create models that you can actually fabricate and use in the real world," says Faruqi. "So MechStyle actually simulates how GenAI-based changes will impact a structure."

How MechStyle Works: AI Meets Physics

The system operates through a sophisticated feedback loop between a generative AI model and a physics simulation engine. Here's the workflow:

Input: Users upload a 3D model or select from preset assets (vases, hooks, pillboxes, etc.) and specify their printing material (e.g., PLA plastic).

Prompting: Users provide text or image prompts to guide the stylization—"cactus-like hook," "rocky texture," or "red magma lampshade."

Generative Modification: The AI model begins altering the 3D geometry to match the requested style.

Structural Simulation: After each significant modification, the system runs a finite element analysis (FEA) simulation. This creates a "heat map" of the model, highlighting regions that can withstand stress versus those becoming dangerously weak.

Adaptive Scheduling: Rather than running expensive simulations after every tiny change, MechStyle intelligently monitors which regions are being modified. When it detects that a change might endanger structural integrity, it triggers a detailed simulation and either stops the stylization or guides the AI to make smaller, safer refinements.

Validation: The system ensures the final model meets structural thresholds before allowing fabrication.

Real-World Applications

The research demonstrates several practical applications:

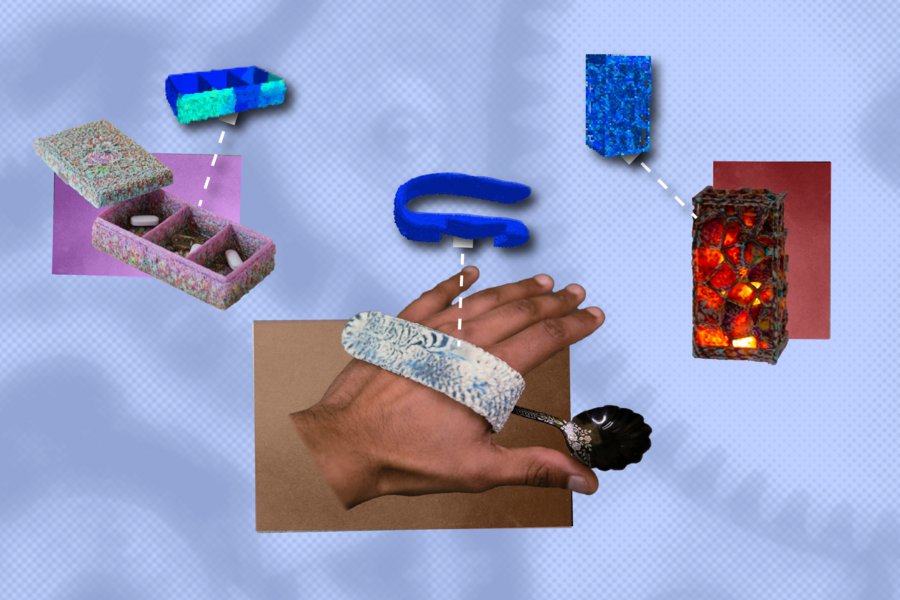

Personal Accessories: The system created a pillbox with a rocky, checkered texture in pink and aqua spots, and eyeglass frames with speckled blue and beige patterns resembling fish scales. Both maintained their functional geometry while achieving the desired aesthetic.

Home and Office Decor: A lampshade designed to look like red magma retained its structural ability to diffuse light and attach to fixtures.

Assistive Technology: Perhaps most importantly, MechStyle can customize medical devices. It produced finger splints for dexterous injuries and utensil grips for motor impairments, ensuring these critical items could sustain daily use while being personalized to user specifications.

Commercial Prototyping: The tool could help designers rapidly prototype accessories for retail environments—toy shops, hardware stores, or craft boutiques—without spending hours manually adjusting CAD files.

Technical Innovation: Adaptive Simulation

The key breakthrough is MechStyle's adaptive scheduling strategy. Running FEA simulations continuously would make the AI generation process prohibitively slow. Instead, the system tracks modification patterns and only runs detailed physics calculations when necessary.

When the AI makes tweaks that endanger specific regions, MechStyle simulates the physics again. If stress thresholds are approached, it can either:

- Stop stylization completely in that area

- Gradually reduce the modification intensity to stay within safe limits

This dynamic approach allowed the team to achieve up to 100% structural viability across 30 different test models with styles including bricks, stones, and cacti.

Current Limitations and Future Directions

MechStyle isn't a complete solution yet. It cannot fix models that are already structurally unsound—if you upload a faulty design, you'll receive an error message. The team plans to add remediation capabilities in future versions.

Additionally, the current system requires users to provide or find existing 3D models. The researchers aim to integrate full generative creation, where users could simply describe an object from scratch ("a bowl with a wavy rim and fluted base") and have the AI both generate and validate the 3D model for fabrication.

Broader Context

This work sits at the intersection of several MIT research threads. Faruqi is advised by Stefanie Mueller, an associate professor and CSAIL principal investigator who has long worked on human-computer interaction and digital fabrication. The project also connects to the MIT Center for Bits and Atoms, directed by Neil Gershenfeld, which explores the boundaries of physical computation.

The research was supported by the MIT-Google Program for Computing Innovation and presented at the Association for Computing Machinery's Symposium on Computational Fabrication. Co-authors include researchers from Google, Stability AI, Northeastern University, and Cornell.

Implications for Design and Manufacturing

MechStyle represents a significant step toward democratizing custom fabrication. Currently, creating personalized 3D-printed objects that are both beautiful and functional requires either deep CAD expertise or a willingness to iterate through multiple failed prints.

By embedding mechanical intelligence directly into the generative process, the system allows non-experts to focus on creative expression rather than engineering calculations. A teacher could create personalized classroom aids, a small business owner could prototype custom products, or an individual could design assistive devices—all with confidence that the final object will work as intended.

The technology also hints at a future where mass customization becomes truly practical. Rather than choosing from pre-designed options, consumers could generate unique items that reflect their personal style, with AI ensuring each creation meets safety and durability standards.

As Faruqi notes, the goal is for designers to "spend more time brainstorming and testing out different 3D designs, instead of assembling and customizing items by hand." In bridging the gap between digital creativity and physical reality, MechStyle brings that future a step closer.

Paper: "MechStyle: Augmenting Generative AI with Mechanical Simulation to Create Stylized and Structurally Viable 3D Models"

Related Links:

Comments

Please log in or register to join the discussion