A research team from the Danish Technological Institute and Heatflow has developed a 3D-printed, fan-less and pump-less liquid cooler that passively dissipates 600 watts of heat from a chip, surpassing its 400-watt design target. The two-phase thermosiphon design operates without moving parts, producing heat at 60-80°C for potential reuse in district heating systems, offering a more efficient and recyclable solution for data center thermal management.

A research collaboration between the Danish Technological Institute and Heatflow has produced a 3D-printed liquid cooler capable of passively dissipating 600 watts of heat from a single chip without any fans or pumps. This achievement surpasses the project's initial 400-watt performance target by 50%, representing a significant advancement in passive cooling technology for high-density computing environments.

The cooler operates on a two-phase thermosiphon principle, a passive heat transfer mechanism that relies on phase changes and gravity. Coolant at the bottom of the heatsink absorbs heat from the chip, evaporating into vapor. This vapor naturally rises to the top of the structure, where it condenses back into liquid, releasing its heat. The condensed liquid then flows back down to the heat source via gravity, completing the cycle without any mechanical assistance. This design eliminates the need for pumps, fans, or other moving parts, which are common points of failure and sources of noise and energy consumption in traditional cooling systems.

The system's thermal performance is notably high. The coolant exiting the heatsink is reported to be at 60-80°C, a temperature range that is significantly more suitable for heat recovery applications compared to conventional data center cooling methods. Standard cooling systems often dissipate heat at lower temperatures, making it difficult and inefficient to capture and reuse. The higher output temperature from this passive cooler makes it a prime candidate for integration into district heating networks or other industrial heating processes, creating a dual-purpose system that cools servers while providing usable thermal energy.

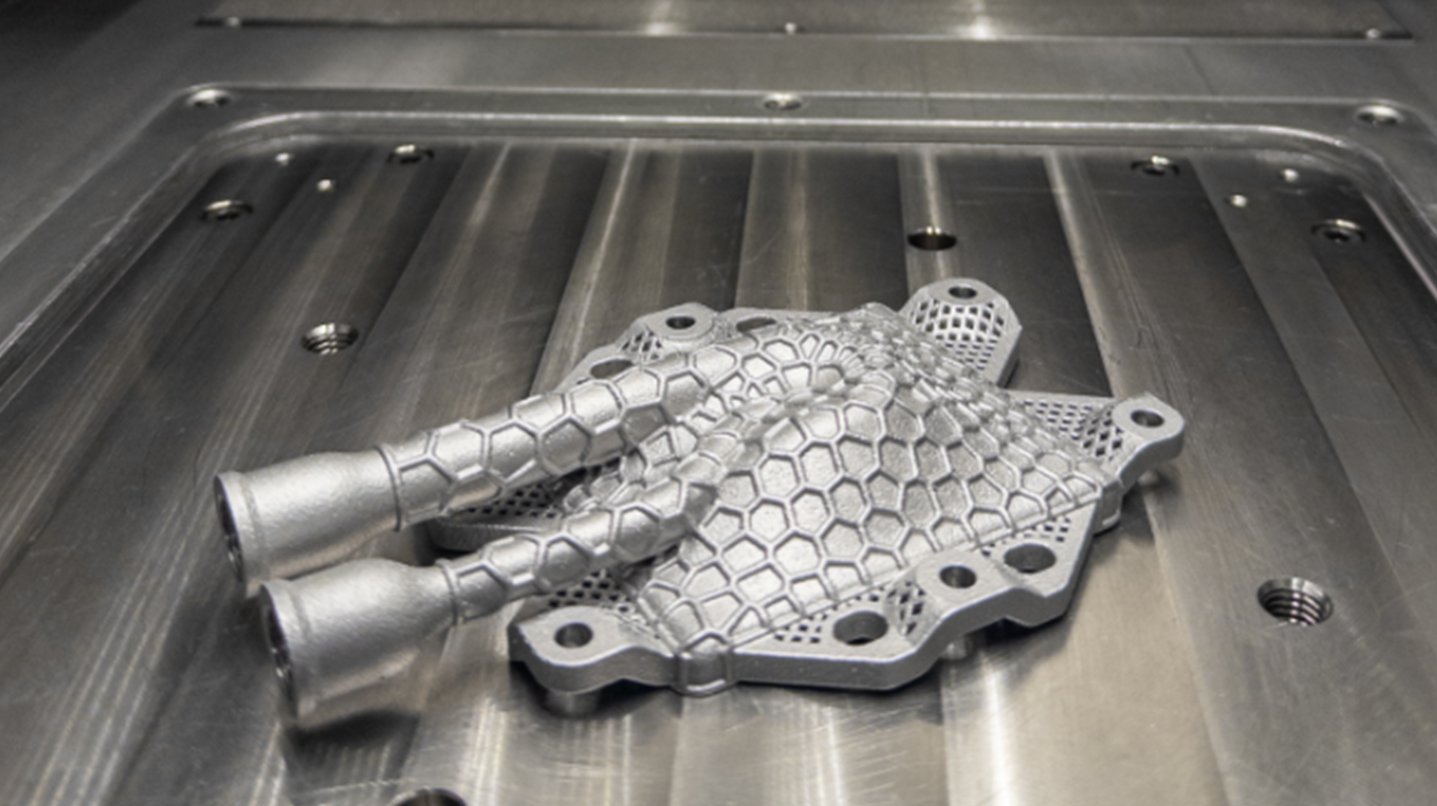

The manufacturing process itself contributes to the system's efficiency and sustainability. Being 3D-printed, the heatsink's complex internal geometry—critical for maximizing surface area and vapor flow—can be produced with minimal material waste. The design reportedly uses a single material, which simplifies production, reduces costs, and facilitates end-of-life recycling. This contrasts with traditional heatsinks, which often involve multiple materials (copper, aluminum, solder, thermal interface material) that complicate recycling.

For data centers, particularly those housing AI accelerators and high-performance computing (HPC) systems, this technology addresses several critical challenges. AI accelerators, such as GPUs and specialized tensor processing units, operate at extremely high power densities and are prone to thermal throttling and accelerated degradation under sustained high temperatures. Lower operating temperatures, as promised by this passive design, can extend hardware lifespan and improve reliability. The passive nature of the system also reduces operational complexity and potential downtime associated with pump or fan failures.

The project's financial efficiency is as remarkable as its technical performance. The entire research and development effort was conducted on a budget of 10 million Danish Crowns (DKK), which translates to approximately $1.56 million USD or €1.34 million EUR. This relatively modest investment yielded a prototype that not only meets but exceeds ambitious performance specifications, suggesting a high potential for commercial viability and scalability.

While the initial application is targeted at data centers, the underlying technology has potential for adaptation in other high-performance computing environments, including workstations and, eventually, consumer desktops. The passive, 3D-printed design offers a path toward quieter, more reliable, and more sustainable cooling solutions across the computing industry.

For more details on the research, visit the Danish Technological Institute and explore related advancements in passive cooling through Heatflow's company initiatives.

Comments

Please log in or register to join the discussion