Elegoo's $449 CoreXY printer delivers reliable four-color printing and engineering-grade material compatibility despite minor usability trade-offs.

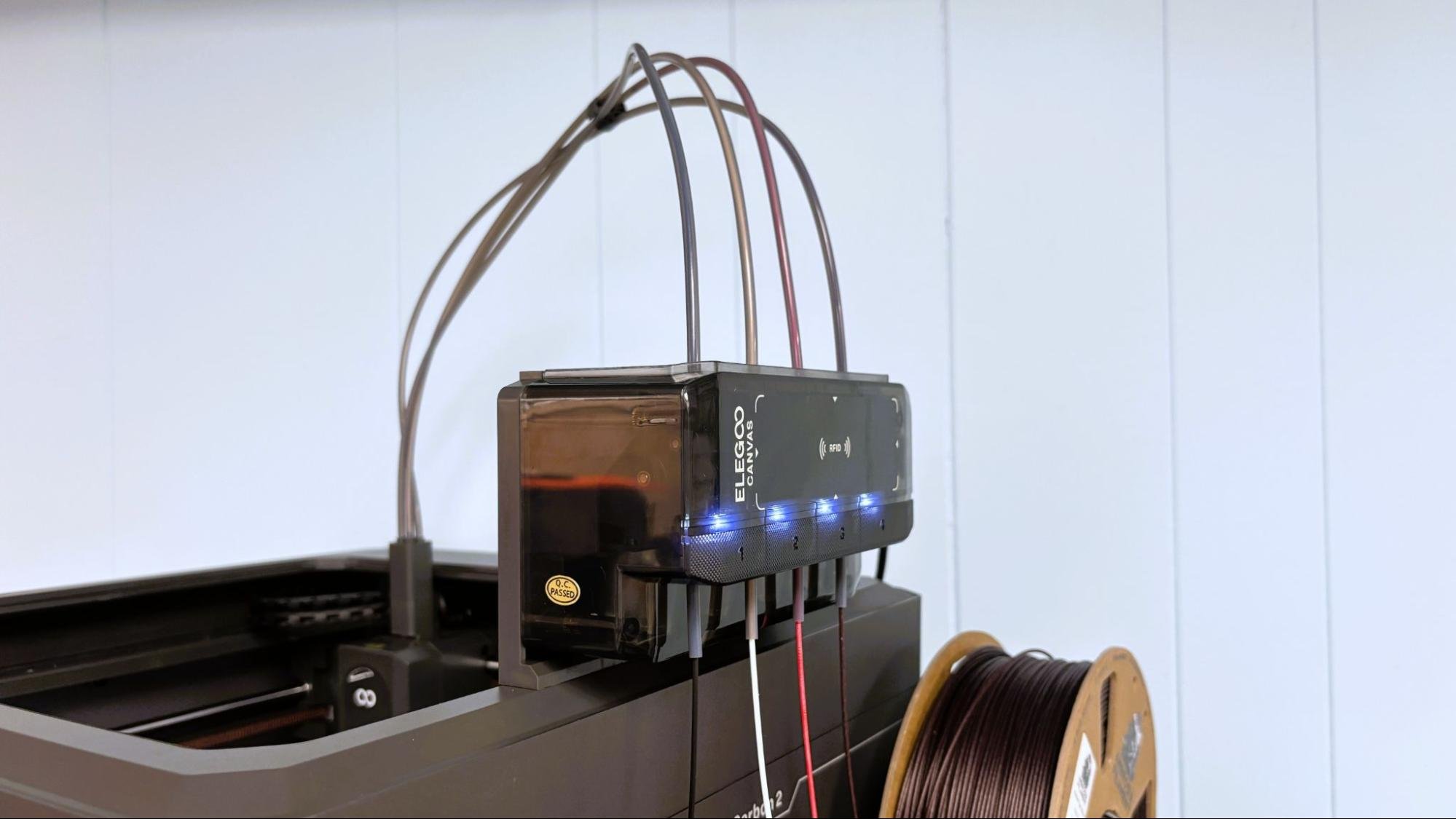

Elegoo has launched the Centauri Carbon 2 Combo, its first four-color 3D printer, expanding the capabilities of its popular CoreXY platform. Priced at $449, this fully enclosed system targets hobbyists and makers seeking multi-material functionality without premium pricing. Unlike modular competitors, the four-filament Canvas system is integrated directly into the machine architecture, using Bowden tubes routed to a hardened steel hot end capable of 350°C extrusion temperatures.

Technical Specifications and Performance

The Centauri Carbon 2 retains the original model's 256mm³ build volume but upgrades to a hardened steel nozzle, heated bed (110°C), and enhanced chamber cooling. Key technical parameters include:

The Centauri Carbon 2 retains the original model's 256mm³ build volume but upgrades to a hardened steel nozzle, heated bed (110°C), and enhanced chamber cooling. Key technical parameters include:

- Motion System: CoreXY architecture with linear rods on all axes

- Material Compatibility: PLA, PETG, TPU (down to 95A), ABS, ASA, PA, PC

- Filament Handling: Quad-feed system with RFID recognition for Elegoo filaments

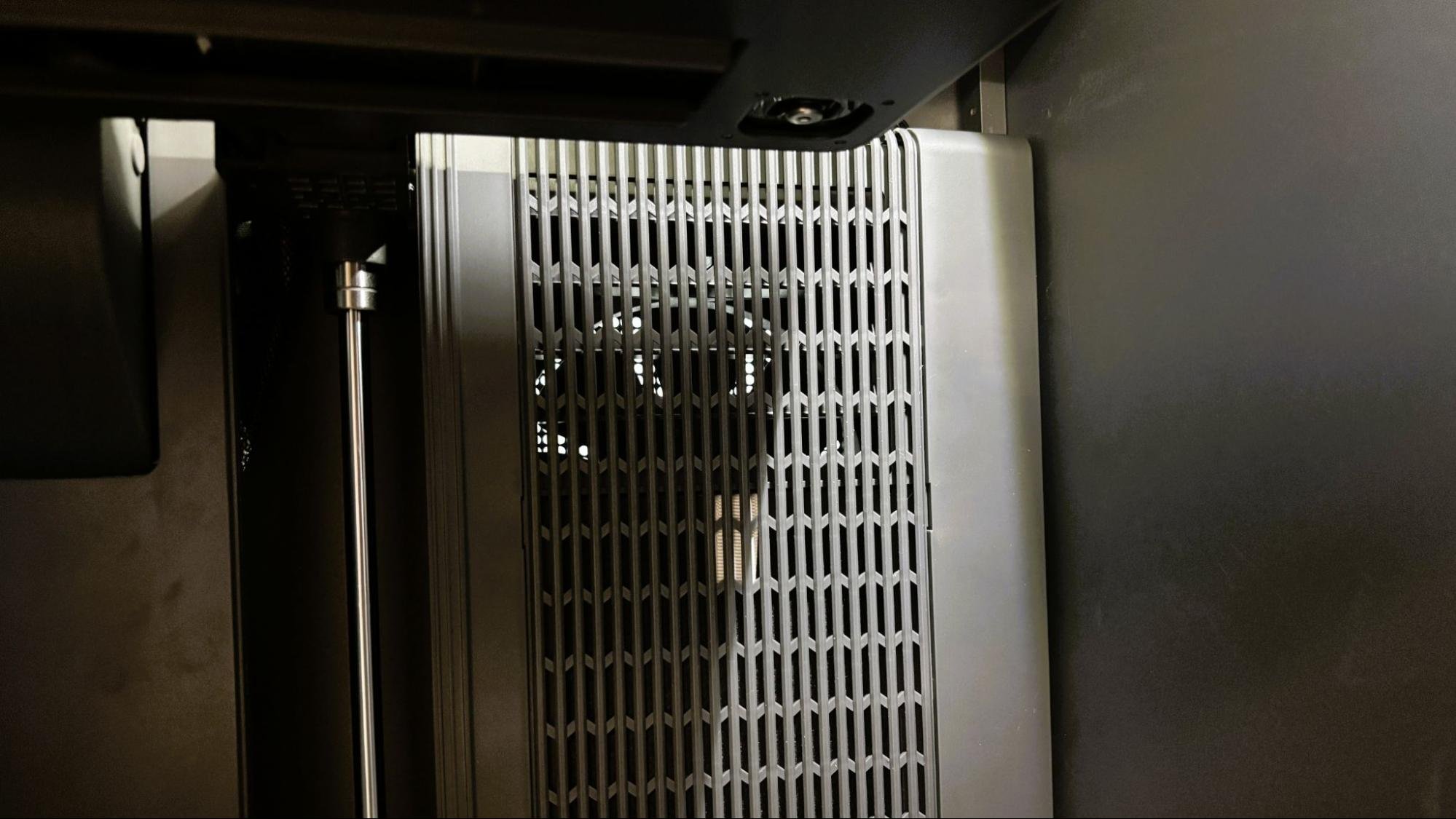

- Thermal Performance: 350°C hot end sustains polycarbonate (PC) and nylon (PA) printing despite lacking active chamber heating

- Throughput: Average print speeds of 100-160mm/s validated across materials

During testing, the printer successfully processed engineering-grade materials including Bambu Lab PAHT CF and Prusa PC Blend. A polycarbonate utility knife print completed at 100mm/s demonstrated exceptional layer adhesion and dimensional stability. The direct-drive extruder handled flexible 95A TPU without jamming, though users must manually override the 250°C default loading temperature when switching to high-temp materials.

Design Implementation Trade-offs

The integrated Canvas system introduces several compromises:

The integrated Canvas system introduces several compromises:

- Filament Management: Proprietary spool holders incompatible with third-party spools caused mechanical failure during testing, requiring printed replacements

- Toolhead Access: PTFE tubes lock permanently into collets, necessitating full hub removal for nozzle maintenance

- Bed Adhesion: Non-textured PEI build plate showed inconsistent grip compared to competitors

Automated calibration sequences reduced setup time to under 20 minutes, and the 5-inch touchscreen delivered responsive control. The upgraded camera system with improved lighting enables reliable print monitoring, though filament naming inconsistencies between ElegooSlicer and printer firmware caused workflow interruptions.

Market Position Analysis

At $449, the Centauri Carbon 2 undercuts competitors significantly:

At $449, the Centauri Carbon 2 undercuts competitors significantly:

| Model | Price | Color System | Key Advantage |

|---|---|---|---|

| Elegoo CC2 | $449 | Integrated 4-color | Full engineering material suite |

| Creality SPARKX i7 | $399 | Multi-color | Compact bedslinger format |

| Bambu Lab P2S | $799 | Modular | Refined ecosystem integration |

| Original Centauri | $289 | Single-color | Budget CoreXY performance |

The printer's CoreXY architecture provides 30-50% faster print speeds versus comparable bedslingers while maintaining dimensional accuracy within ±0.1mm across tested models. For makers prioritizing multi-material capability with engineering polymers, the CC2 delivers 92% of premium printer functionality at 56% of the Bambu P2S's cost. However, Elegoo's non-modular approach means existing Centauri owners cannot retrofit the color system.

Elegoo's aggressive pricing strategy pressures competitors to match sub-$500 multi-material capabilities. With reliable TPU handling and proven PC/PA performance despite lacking heated chambers, the CC2 sets new expectations for budget-conscious technical printing. The spool holder design flaws and temperature management limitations represent opportunities for iterative refinement in future models.

Comments

Please log in or register to join the discussion