MIT researchers have created load-bearing floor trusses using recycled plastic composites, achieving performance exceeding building standards while reducing material weight by 30% compared to wood. This approach addresses both housing shortages and plastic waste challenges through additive manufacturing.

The global construction industry faces twin sustainability challenges: meeting unprecedented housing demand while reducing reliance on virgin materials. MIT engineers have developed a solution that converts single-use plastics into structural building components using industrial-scale 3D printing technology.

Technical approach

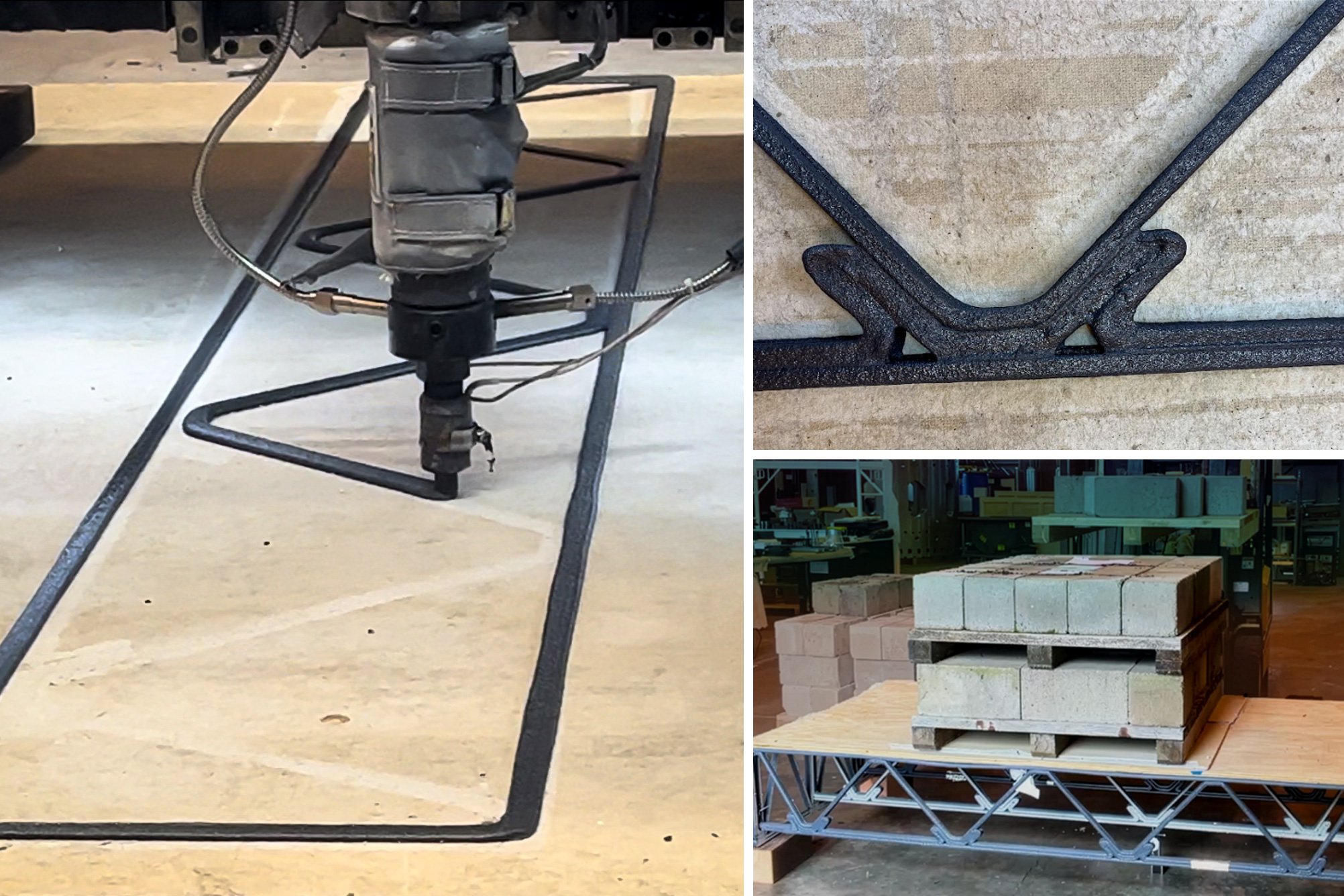

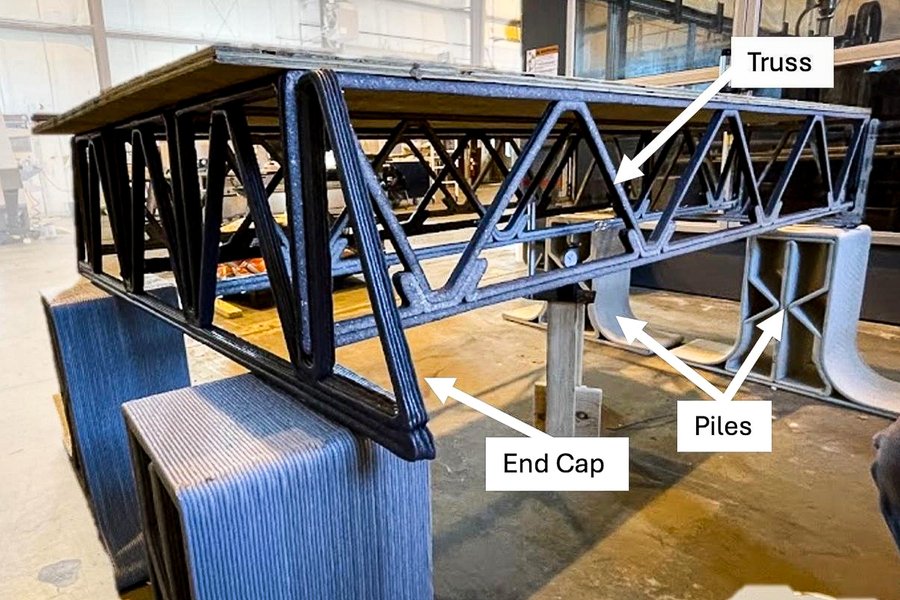

The research team from MIT's Laboratory for Manufacturing and Productivity designed floor trusses using polymer composites containing recycled PET and glass fibers. Their system employs an industrial-scale 3D printer capable of depositing 80 pounds of material per hour. The truss design emerged from computational simulations that optimized stiffness-to-weight ratio, resulting in a modified ladder pattern with reinforced nodal connections.

Three stages of floor truss production showing material extrusion, joint detailing, and layered construction

Three stages of floor truss production showing material extrusion, joint detailing, and layered construction

Each 8-foot truss weighs approximately 13 pounds - 30% lighter than comparable wood structures - and prints in under 13 minutes. When assembled into a 4x8-foot floor frame with plywood sheathing, the system demonstrated exceptional load-bearing capacity:

- Withstood 300+ pounds with minimal deflection (exceeding HUD standards)

- Maintained structural integrity until catastrophic failure at 4,000 pounds

- Demonstrated stiffness meeting U.S. building codes

Material innovation

The team intentionally works with "dirty" recycled plastics - materials containing residual liquids or contaminants that typically degrade mechanical properties. By developing processing techniques that accommodate these impurities, they aim to create a circular materials economy where plastic waste streams directly feed construction manufacturing.

"Current prototypes use aerospace-grade recycled composites, but we're testing formulations with post-consumer bottles and food containers," explains lead researcher AJ Perez from the MIT Laboratory for Manufacturing and Productivity. "The goal is localized production - shredding plastic near stadiums or dense urban areas and printing structural components on-site."

Closeup of printed truss showing integrated reinforcement at critical stress points

Closeup of printed truss showing integrated reinforcement at critical stress points

Systemic implications

This technology addresses multiple pressure points in global construction:

- Material scarcity: Replaces wood framing (projected to require triple current Amazon rainforest timber by 2050)

- Transport efficiency: Printed components are lightweight enough for pickup truck transport vs. heavy lumber trucks

- Construction speed: Complete house frames could be printed in hours rather than days

- Waste reduction: Diverts plastic from landfills/oceans while creating durable structures

Path to implementation

While initial results are promising, challenges remain:

- Cost parity: Current production costs exceed wood framing

- Code approval: Requires extensive durability testing for building code compliance

- Material consistency: Developing reliable performance with highly variable waste streams

The team is expanding their research to other structural elements through the MIT HAUS initiative, including foundation pilings and roof trusses. Their work aligns with MIT's broader efforts in sustainable construction technologies like the cold spray bridge repair system and voxel-based structures.

MIT researchers testing infrastructure repair technologies under real-world conditions

MIT researchers testing infrastructure repair technologies under real-world conditions

This research demonstrates the viability of polymer additive manufacturing for primary structural applications. As Perez notes: "We're not just making plastic bricks - we're reengineering construction logistics from material sourcing through final assembly." The team's published findings detail the technical specifications and testing protocols for their truss system.

For ongoing developments in sustainable manufacturing, follow the MIT Department of Mechanical Engineering and School of Engineering.

Comments

Please log in or register to join the discussion