Oak Ridge National Laboratory has successfully irradiated two 3D-printed stainless steel experimental capsules in its High Flux Isotope Reactor, proving additive manufacturing can meet nuclear safety demands. This breakthrough accelerates materials testing for next-gen reactors and signals a potential shift toward printed nuclear components.

In a significant leap for nuclear component manufacturing, the Department of Energy’s Oak Ridge National Laboratory (ORNL) has demonstrated that additively manufactured stainless steel capsules can withstand the brutal conditions inside a nuclear reactor. The successful month-long irradiation test at ORNL’s High Flux Isotope Reactor (HFIR) marks a pivotal validation of 3D printing for critical nuclear applications.

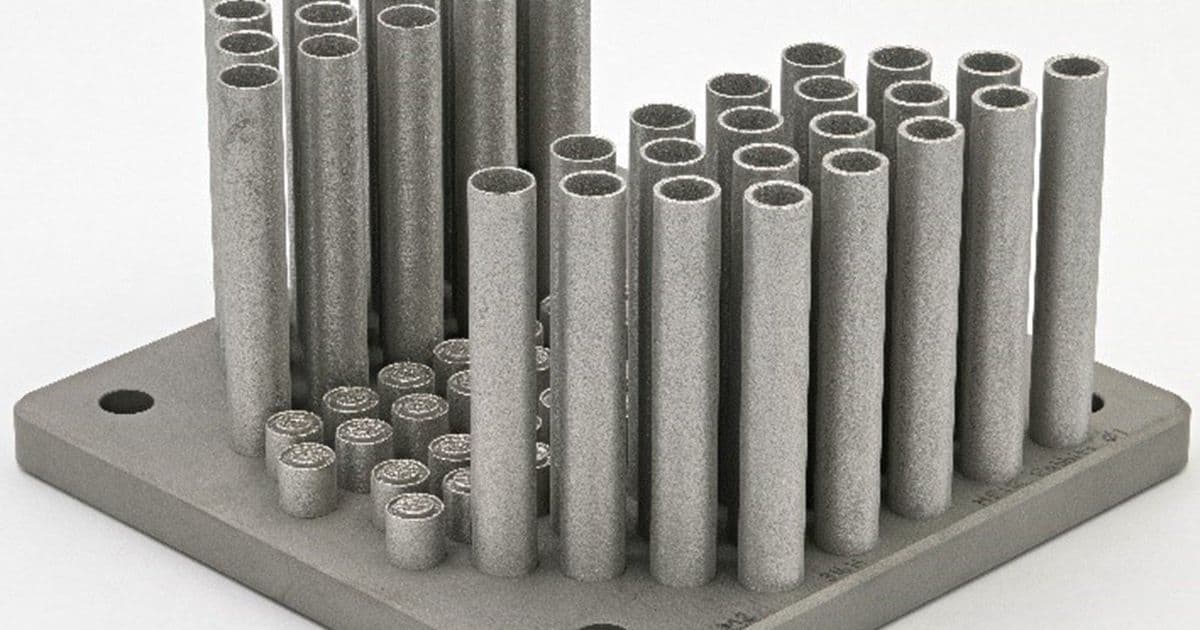

Caption: 3D-printed stainless steel capsules prepared for irradiation testing at ORNL. Credit: ORNL, U.S. Dept. of Energy

Caption: 3D-printed stainless steel capsules prepared for irradiation testing at ORNL. Credit: ORNL, U.S. Dept. of Energy

Engineering Nuclear-Grade Resilience

Researchers used a laser powder-bed fusion system at ORNL’s Manufacturing Demonstration Facility (MDF) to fabricate the capsules from 316H stainless steel – a material selected for its proven combination of properties in nuclear environments:

- High-temperature strength

- Exceptional corrosion and radiation resistance

- Nuclear-grade performance history

- Reliable weldability

These capsules serve as containment vessels for materials during irradiation experiments, acting as critical pressure barriers. Their integrity under HFIR’s intense neutron flux—one of the highest in the world—confirms printed components can meet the rigorous safety standards demanded in nuclear settings.

Accelerating Nuclear Innovation

Traditional fabrication of custom irradiation capsules is costly and time-intensive, often creating bottlenecks in materials research. Additive manufacturing slashes lead times and costs, enabling faster iteration for next-generation reactor fuels and materials.

"As we demonstrate the reliability of these printed components, we’re looking at a future where additive manufacturing might become standard practice in producing other critical reactor parts," said Ryan Dehoff, Director of the MDF.

Richard Howard, Group Leader in ORNL’s Nuclear Energy and Fuel Cycle Division, emphasized the broader impact: "Additive manufacturing will expand my group’s toolset to develop innovative experiments... to qualify advanced reactor technologies to survive very harsh conditions."

Caption: Close-up of a 3D-printed capsule showing identification markings. Credit: ORNL, U.S. Dept. of Energy

Caption: Close-up of a 3D-printed capsule showing identification markings. Credit: ORNL, U.S. Dept. of Energy

The Road to Standardization

Sponsored by DOE’s Advanced Materials and Manufacturing Technologies program, this milestone establishes a foundation for qualifying more complex printed nuclear components. The ability to rapidly produce and test custom geometries unlocks new experimental designs previously deemed impractical. With HFIR and MDF both designated DOE user facilities, this advancement directly supports national efforts to accelerate advanced reactor deployment through materials innovation.

While regulatory pathways remain, ORNL’s successful test signals that additive manufacturing is poised to transform how nuclear components are designed, tested, and certified—potentially reshaping the supply chain for next-generation nuclear energy systems.

Comments

Please log in or register to join the discussion