Embodied intelligence startup X Square Robot raised $140 million in fresh capital, securing backing from China's three largest internet giants while advancing its industrial automation technology.

X Square Robot, a Shenzhen-based developer of general-purpose AI robots, has completed a $140 million Series A++ funding round led by ByteDance, Sequoia China, and Shenzhen Capital Group. This investment marks the first deployment from Shenzhen Capital's newly established AI-focused fund and follows prior backing from Meituan and Alibaba, making X Square Robot the only embodied intelligence company supported by China's three dominant internet platforms.

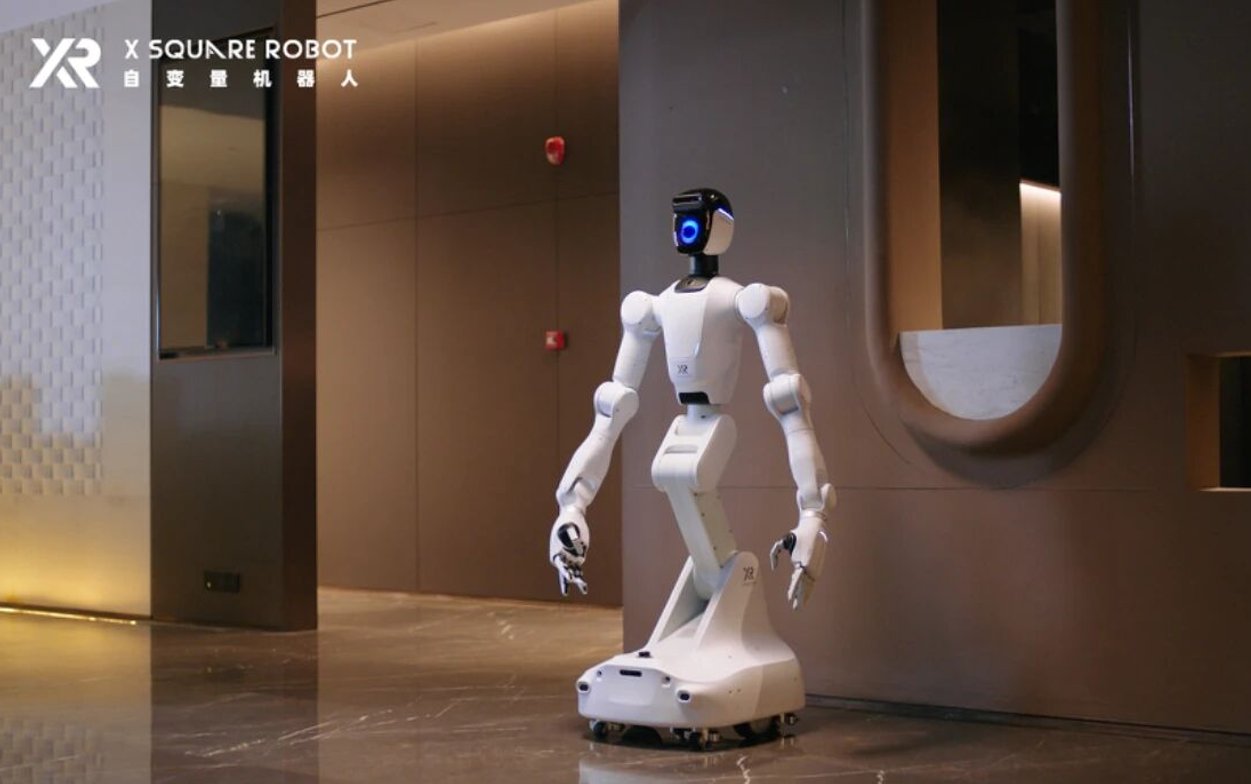

Founded in December 2023, X Square Robot targets industrial inefficiencies through adaptable automation systems. The company's Quantum series robots address labor-intensive processes in manufacturing and logistics by performing complex physical tasks in unstructured environments. Their technology combines proprietary AI models with fully self-developed hardware components, enabling flexible deployment scenarios beyond pre-programmed workflows.

The new capital will accelerate development of the Quantum platform and expand commercial implementations. Current applications include warehouse logistics automation and precision assembly lines, with pilots demonstrating 40% reduction in manual intervention for selected processes. Unlike single-task industrial robots, X Square's systems leverage multimodal perception to dynamically adapt to changing conditions on factory floors.

Investor participation signals confidence in embodied intelligence as a growth vector. ByteDance's involvement suggests potential integration with e-commerce fulfillment operations, while Sequoia's continued support reflects belief in the platform's scalability. The company maintains its Shenzhen headquarters near manufacturing clusters, facilitating rapid iteration with industrial partners.

With total disclosed funding now exceeding $200 million, X Square Robot enters its next development phase positioned to transform how factories approach automation. The company's approach avoids hyperspecialized solutions in favor of adaptable systems that learn through operational experience, potentially reducing implementation costs for mid-size manufacturers.

Comments

Please log in or register to join the discussion