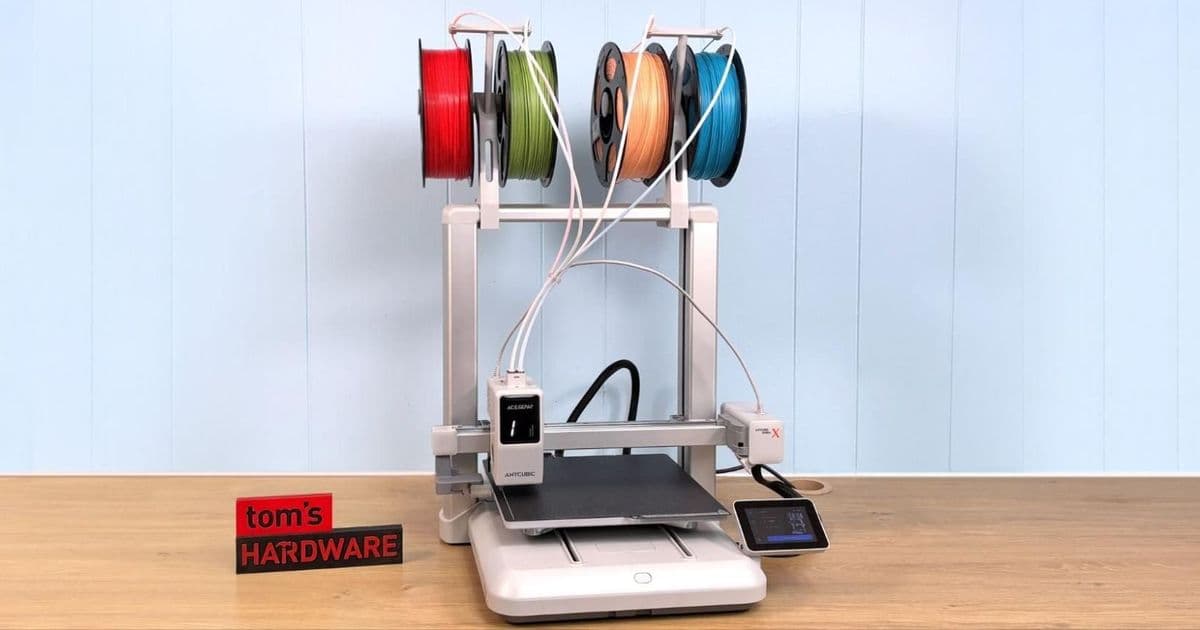

Anycubic's Kobra X delivers Bambu Lab A1-tier multicolor capabilities at $279 by integrating its filament-switching system directly into the toolhead, reducing swap times by 61% and waste by 42% compared to external AMS solutions.

Architectural Breakthrough in Toolhead Design

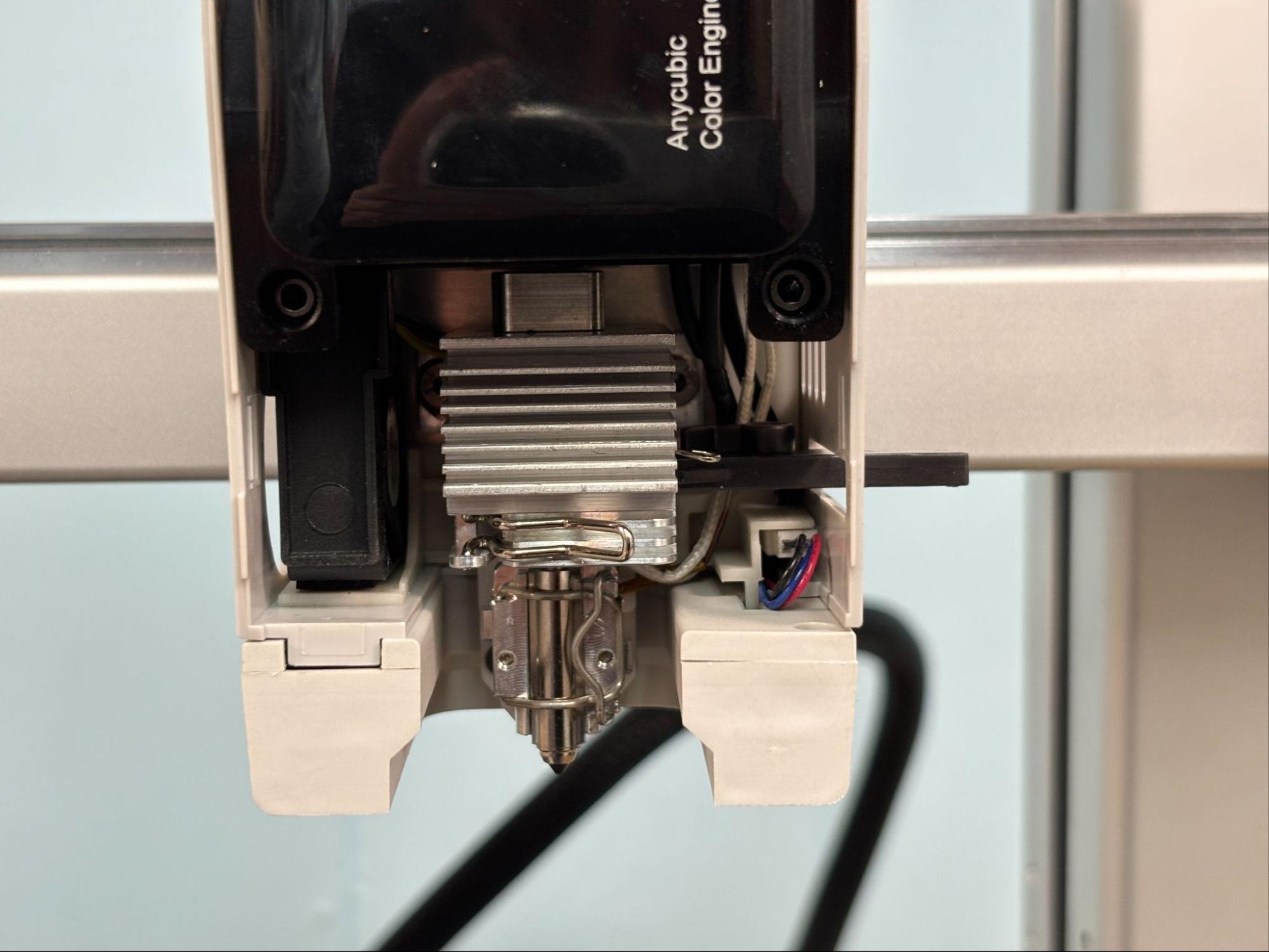

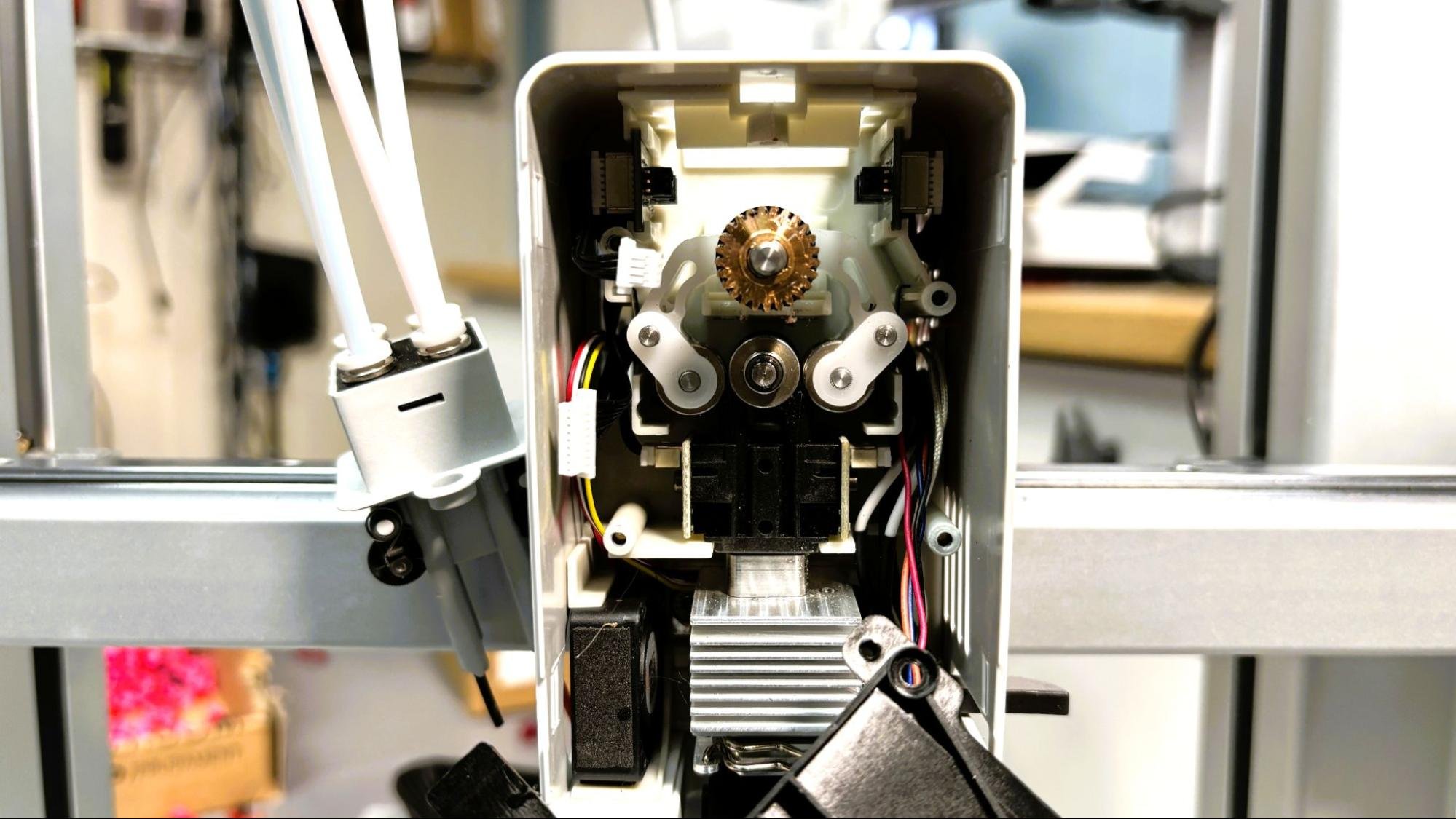

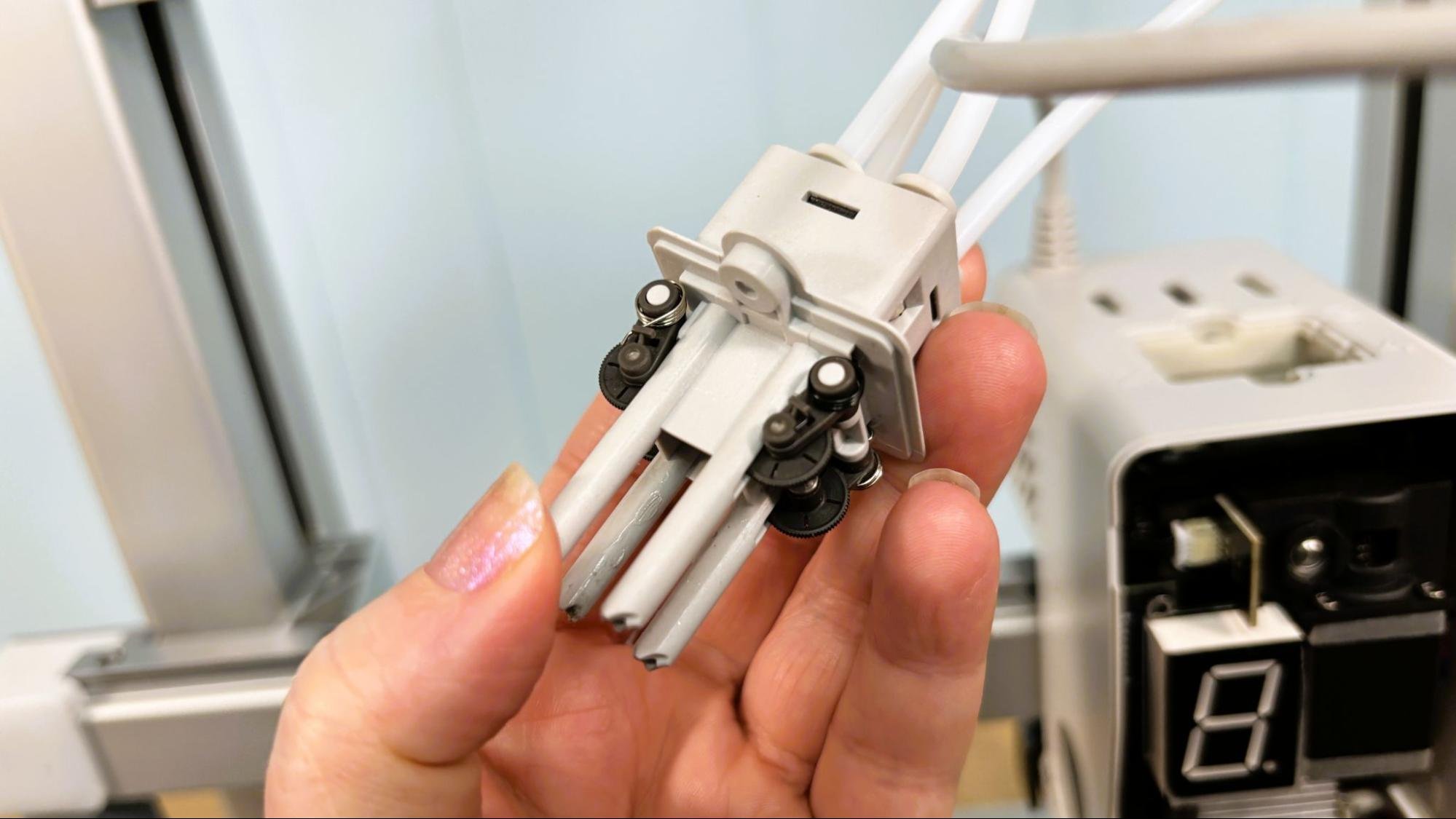

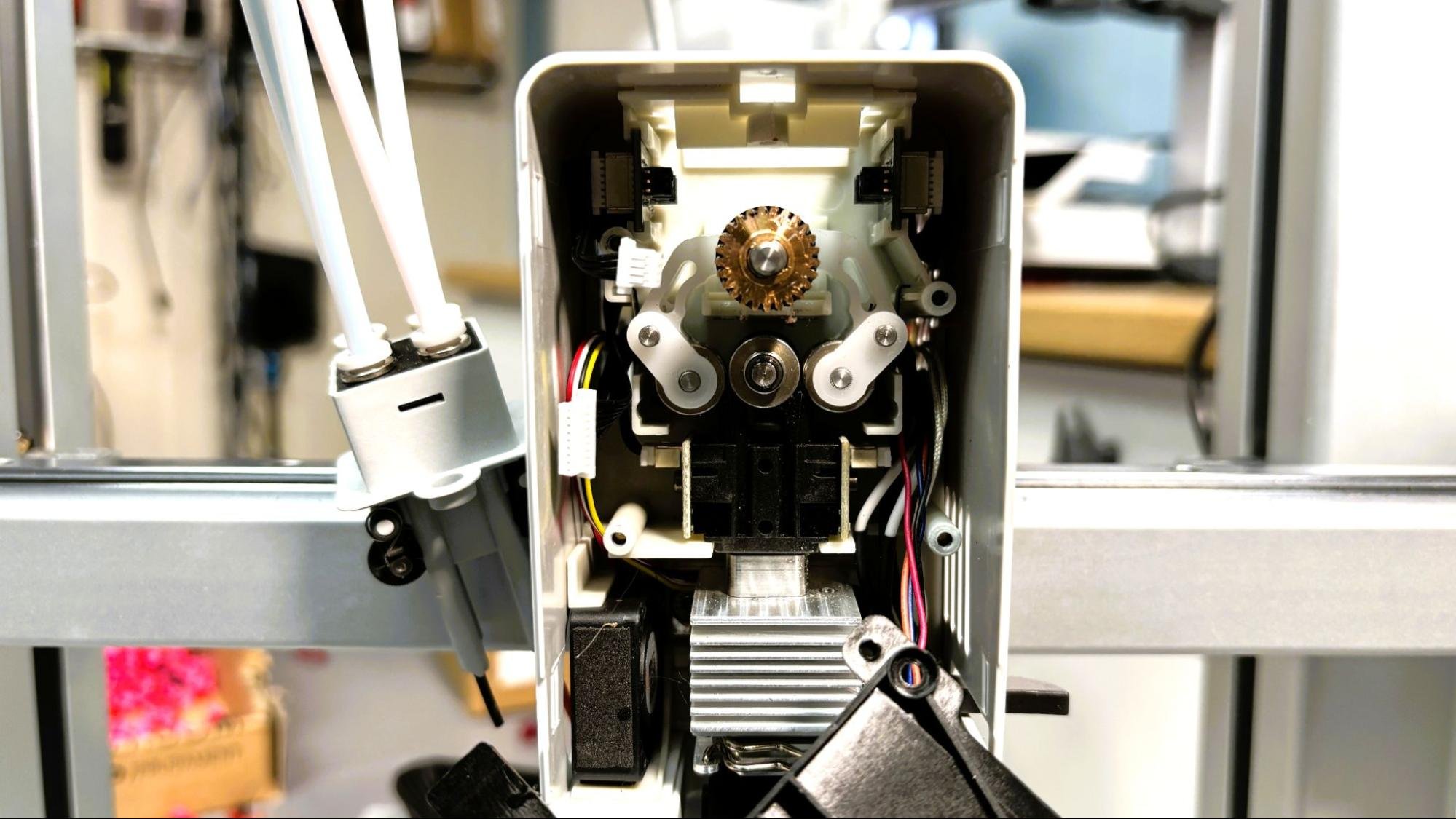

The Anycubic Kobra X (product page) achieves its price-performance advantage through a radical rethinking of multicolor extrusion mechanics. Unlike traditional external AMS units requiring complex filament routing, the Kobra X's ACE Gen 2 system fits entirely within the print head assembly. This architectural shift enables:

- 10mm nozzle-to-cutter distance (vs 30-50mm in competitors)

- 30mm filament retraction per color change (Bambu A1: 90mm+)

- 19-color expandability via optional ACE 2 Pro hubs

Performance Benchmarks: Speed and Waste Reduction

Quantitative testing reveals significant operational advantages:

| Metric | Kobra X | Bambu Lab A1 | Delta |

|---|---|---|---|

| Avg. swap time | 35s | 90s | -61% |

| 776-swap print duration | 13h10m | 23h08m | -43% |

| Purge waste per swap | 0.24g | 0.34g | -29% |

| 4-color model waste | 192g | 263g | -27% |

These efficiencies stem from the mechanical simplification of moving filament selection directly to the extrusion point. The motor-driven camshaft system ([detail view]( )) engages only the active filament's drive gears, eliminating cross-contamination risks while maintaining compatibility with TPU down to 85A hardness.

)) engages only the active filament's drive gears, eliminating cross-contamination risks while maintaining compatibility with TPU down to 85A hardness.

Manufacturing and Supply Chain Implications

Anycubic's design choices have significant production ramifications:

- Reduced Bill of Materials: Integrated ACE Gen 2 eliminates external enclosures, tubing, and separate control boards

- Simplified Assembly: Ships in two main modules (base + gantry) with 8-screw installation

- Logistics Optimization: 9.5kg total weight (20% lighter than comparable systems)

The $279 early-bird pricing (30% below MSRP) suggests aggressive yield optimization on the custom toolhead assembly. Component reuse from Anycubic's Kobra 3 Max line likely contributes to cost containment.

Market Disruption Potential

The Kobra X threatens several market segments simultaneously:

- Bedslinger Premium Tier: Undercuts Bambu A1 by $120 at launch

- Entry-Level CoreXY: Competes on multicolor speed at half the price of base CoreXY models

- Prosumer Workflow: 19-color expandability approaches specialty printer capabilities

Technical Limitations and Tradeoffs

Engineering constraints manifest in two primary areas:

- Spool Management: Stationary top-mounted spools require manual untangling during rapid retractions

- Slicer Maturity: Anycubic SlicerNext (GitHub) lacks Bambu Studio's granular parameter controls

- Thermal Management: No active spool drying despite 300°C nozzle capability

These reflect calculated compromises to hit the sub-$300 price point while maintaining print quality comparable to $500+ systems.

Industrial Design Analysis

The Kobra X's fully enclosed motion system and hidden linear rails ([gantry detail]( )) demonstrate thoughtful DFM (Design for Manufacturing):

)) demonstrate thoughtful DFM (Design for Manufacturing):

- Brushed aluminum covers mask injection-molded structural components

- Single Z-axis stepper with top belting reduces alignment complexity

- Toolhead-mounted status display eliminates separate control modules

This approach yields a 455 × 445.3 × 461.3mm footprint that minimizes shipping volume while maximizing the 260³mm build area.

Conclusion: A New Benchmark in Accessible Multicolor Printing

The Kobra X represents a strategic inflection point in consumer 3D printing. By achieving Bambu-grade multicolor performance at Creality-level pricing, Anycubic pressures competitors to either match their toolhead integration or concede the budget multicolor segment. With March 2026 shipments planned, the industry has 18 months to respond - an eternity in 3D printing's current innovation cycle.

For detailed specifications and pre-orders, visit Anycubic's official product page.

Comments

Please log in or register to join the discussion