Harvard engineers develop a novel 3D printing technique that combines multiple materials through a rotating nozzle to create flexible structures with built-in motion logic, potentially revolutionizing soft robotics manufacturing.

A team of engineers at Harvard University has achieved a significant breakthrough in both 3D printing technology and soft robotics, developing a novel technique that creates fully flexible structures capable of twisting and changing shape on demand. The innovation, led by former postgraduate student Natalie Larson and graduate student Jackson Wilt at the John A. Paulson School of Engineering and Applied Sciences, merges several existing methods into what they call "rotational multi-material 3D printing."

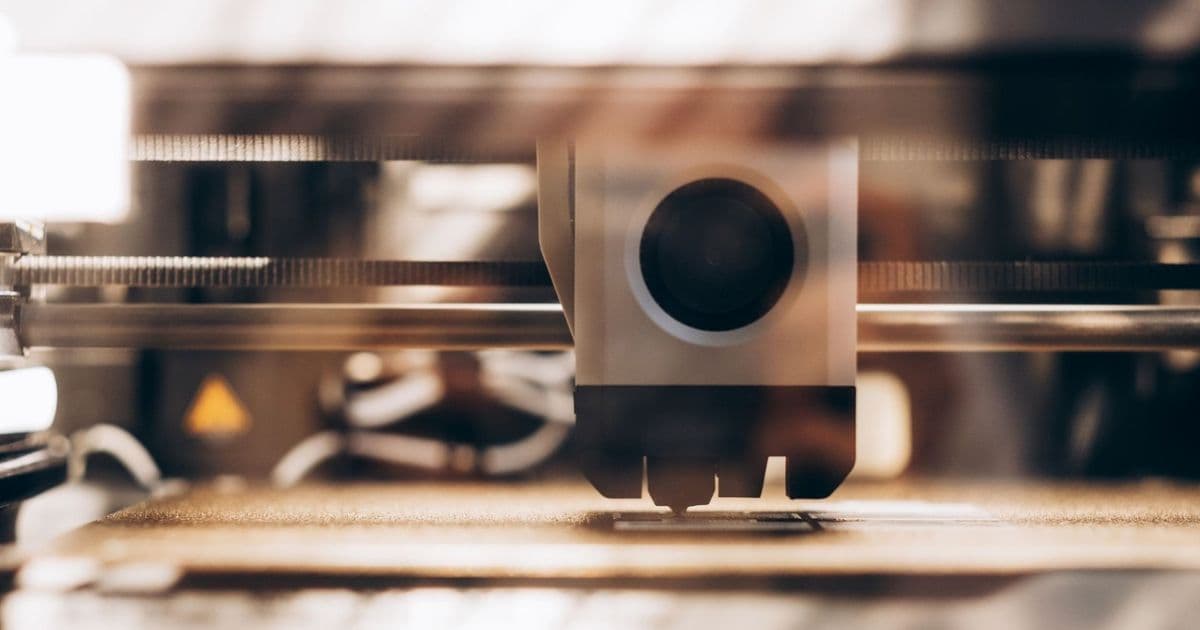

This new approach prints multiple materials simultaneously through a single nozzle that continuously rotates as it deposits material. By adjusting the nozzle's design, rotation speed, and flow rate, the researchers can precisely control how different materials combine within the structure during the printing process.

The technique employs a dual-material system where a durable polyurethane forms the outer layer, providing structural integrity, while a poloxamer-based polymer—described as having a hair gel-like consistency—creates the inner structure. Once printing is complete, the gel-like material is washed away, leaving behind a series of hollow tubes that function as artificial muscles. These hollow channels can be pressurized with air or fluid to create controlled movements in various directions.

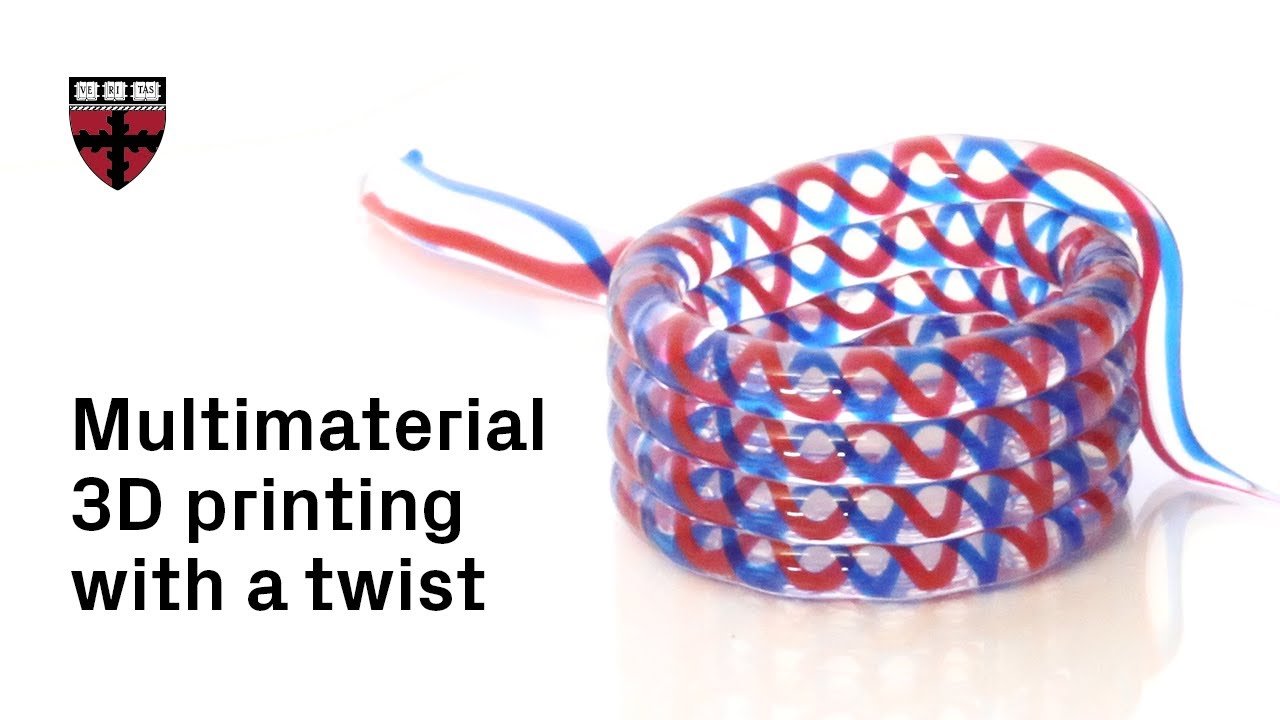

What makes this development particularly noteworthy is the ability to program motion logic directly into the printed structure. According to Wilt, the team achieves this by using two different materials that can be "rotated to program the direction the robot bends when inflated." This means the robot's movement patterns are determined during the printing process rather than requiring additional mechanical components or complex assembly.

The researchers demonstrated the technology's capabilities using two compelling examples: a flower-like spiral actuator that unfurls when inflated, and a hand-like gripper with fingers that can curl around objects. These demonstrations showcase the potential for creating complex, functional soft robotic systems with minimal post-processing.

Traditional soft robotics manufacturing typically involves casting soft materials into molds and encapsulating them together layer by layer—a time-consuming process that requires numerous individual components and assembly steps. The Harvard team's approach could dramatically simplify this workflow by enabling the creation of complex, malleable structures in a single print operation.

The implications of this technology extend across multiple industries if it can be scaled for industrial production. The combination of speed and simplicity offered by this 3D printing method addresses two of the most significant challenges in soft robotics manufacturing. Rather than assembling multiple components, engineers could potentially design and print entire functional robotic systems with embedded movement logic.

Larson and Wilt's work has been published in the journal Advanced Materials and is now subject to a filed patent, indicating the team's confidence in the commercial potential of their innovation. The research represents a convergence of advances in materials science, mechanical engineering, and additive manufacturing that could accelerate the development and deployment of soft robotic systems.

This breakthrough comes at a time when soft robotics is gaining increasing attention for applications ranging from medical devices and prosthetics to industrial automation and search-and-rescue operations. The ability to create programmable, flexible structures with embedded functionality could open new possibilities in fields where traditional rigid robotics face limitations.

The rotational multi-material 3D printing technique exemplifies how incremental advances in manufacturing technology can lead to transformative capabilities in robotics. By rethinking how materials are deposited and combined during the printing process, the Harvard team has created a pathway to more sophisticated and accessible soft robotic systems.

As the field continues to evolve, this innovation may prove to be a pivotal moment in the development of soft robotics, potentially enabling new applications and use cases that were previously impractical due to manufacturing constraints. The combination of programmable motion, material efficiency, and simplified production processes positions this technology as a promising foundation for the next generation of flexible robotic systems.

Comments

Please log in or register to join the discussion