MIT engineers develop a computational framework for designing 3D-printed woven metamaterials that can stretch, deform, and fail in predictable ways, opening new possibilities for soft robotics, wearables, and functional textiles.

MIT engineers have developed a groundbreaking computational framework that enables the design and fabrication of 3D-printed woven metamaterials with unprecedented control over their mechanical behavior. Published in Nature Communications on January 26, 2026, this research from MIT's Department of Mechanical Engineering introduces a new class of soft, compliant materials that can stretch, deform, and fail in predictable, programmable ways.

From Stiff to Soft: A New Frontier in Metamaterials

Metamaterials have revolutionized engineering over the past decade by achieving extraordinary properties through internal microstructure rather than chemical composition. However, most existing metamaterials have focused on stiffness and strength, leaving a gap in soft, deformable materials for emerging applications.

"Soft materials are required for emerging engineering challenges in areas such as soft robotics, biomedical devices, or even for wearable devices and functional textiles," explains Carlos Portela, the Robert N. Noyce Career Development Professor and associate professor of mechanical engineering at MIT.

The 3D Woven Metamaterial Revolution

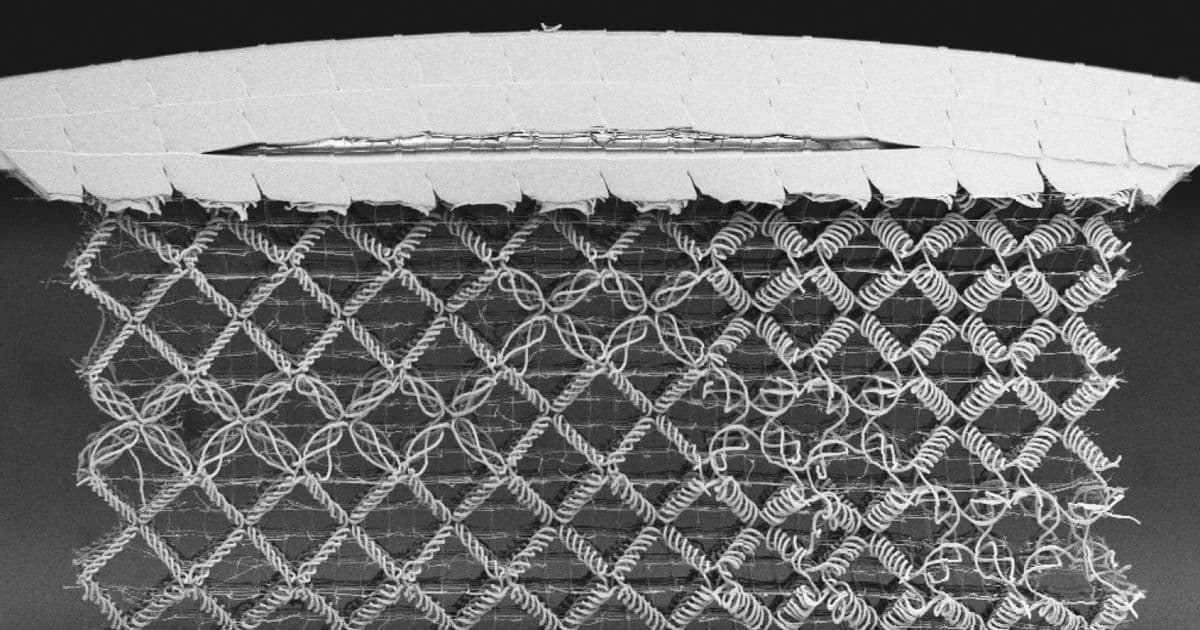

The new framework introduces 3D woven metamaterials composed of intertwined fibers that self-contact and entangle, creating unique mechanical properties. These materials consist of fundamental building blocks called woven unit cells, which can be functionally graded by controlling design parameters such as fiber radius and pitch.

This approach breaks free from the constraints of traditional weaving and knitting, which have been limited by hardware capabilities for centuries. "Normal knitting or weaving have been constrained by the hardware for hundreds of years — there's only a few patterns that you can make clothes out of, for example — but that changes if hardware is no longer a limitation," Portela notes.

A Universal Design Framework

The research team developed an algorithm that provides a graph representation of the metamaterial, dictating how each fiber is placed and connected. This universal design framework generates complex 3D woven metamaterials with a wide range of properties, and the team has released open-source code that allows users to create custom designs, generate printable files, and simulate material behavior.

Programmable Deformation and Failure

One of the most significant advances is the ability to predict and control how these materials deform and fail. The simulation framework captures complex phenomena such as self-contact within fibers and entanglement, allowing designers to predict deformation patterns and design materials that resist tearing in specific ways.

"Because this framework allows these metamaterials to be tailored to be softer in one place and stiffer in another, or to change shape as they stretch, they can exhibit an exceptional range of behaviors that would be hard to design using conventional soft materials," says Molly Carton, lead author of the study and now an assistant research professor at the University of Maryland.

Practical Applications

The technology opens up numerous possibilities across multiple industries:

- Wearable sensors that move naturally with human skin

- Functional textiles for aerospace and defense applications

- Flexible electronic devices with integrated sensing capabilities

- Soft robotics components that require controlled deformation

- Biomedical devices that need to conform to body shapes

Design Freedom and Failure Control

Perhaps the most exciting aspect of this research is the ability to tailor failure modes. "The most exciting part was being able to tailor failure in these materials and design arbitrary combinations," says Portela. "Based on the simulations, we were able to fabricate these spatially varying geometries and experiment on them at the microscale."

This represents the first tool for designing, printing, and simulating extensible and tough metamaterials with predictable failure patterns. The framework substantially expands the property space of woven metamaterials by introducing new design building blocks.

Democratizing Metamaterial Design

Until now, designing complex 3D lattices required manual, painstaking effort that limited the number of designs tested. "We've been able to describe how these woven lattices work and use that to create a design tool for arbitrary woven lattices," Carton explains. "With that design freedom, we're able to design the way that a lattice changes shape as it stretches, how the fibers entangle and knot with each other, as well as how it tears when stretched to the limit."

The team has released their framework as a software tool, hoping to enable researchers across disciplines to explore new possibilities. "In releasing this framework as a software tool, our hope is that other researchers will explore what's possible using woven lattices and find new ways to use this design flexibility," Carton says. "I'm looking forward to seeing what doors our work can open."

Technical Innovation and Validation

The research team, which included James Utama Surjadi, Bastien F. G. Aymon, and Ling Xu, validated their framework through both simulation and physical experimentation. The work leveraged MIT.nano's fabrication and characterization facilities, demonstrating the practical feasibility of the approach.

By providing a computational tool that bridges design, simulation, and fabrication, this research represents a significant step forward in the field of soft metamaterials. The ability to program not just the desirable properties of a material, but also its failure modes, opens up new possibilities for creating materials that are both functional and safe in demanding applications.

The paper "Design framework for programmable three-dimensional woven metamaterials" is available in the journal Nature Communications, marking a significant milestone in the evolution of metamaterial design and fabrication.

Comments

Please log in or register to join the discussion