MIT researchers have developed a revolutionary 3D-printing platform that can produce fully functional electric linear motors using multiple functional materials in a single manufacturing step, potentially transforming how electronic devices are made.

When a motor fails on a factory floor, production grinds to a halt while engineers scramble to find replacement parts—often ordering from distributors hundreds of miles away and incurring costly delays. MIT researchers have developed a solution that could transform this scenario: a multimaterial 3D-printing platform capable of fabricating complex electric machines like linear motors in just hours, using five different functional materials in a single manufacturing step.

Revolutionizing Electric Machine Manufacturing The breakthrough comes from MIT's Microsystems Technology Laboratories, where researchers led by principal research scientist Luis Fernando Velásquez-García have created a system that overcomes the traditional limitations of 3D printing with multiple functional materials. Their platform can process electrically conductive materials, hard magnetic materials, and other functional components simultaneously, enabling the complete fabrication of electric machines without the specialized equipment and complicated processes typically required.

"This is a great feat, but it is just the beginning," says Velásquez-García. "We have an opportunity to fundamentally change the way things are made by making hardware onsite in one step, rather than relying on a global supply chain."

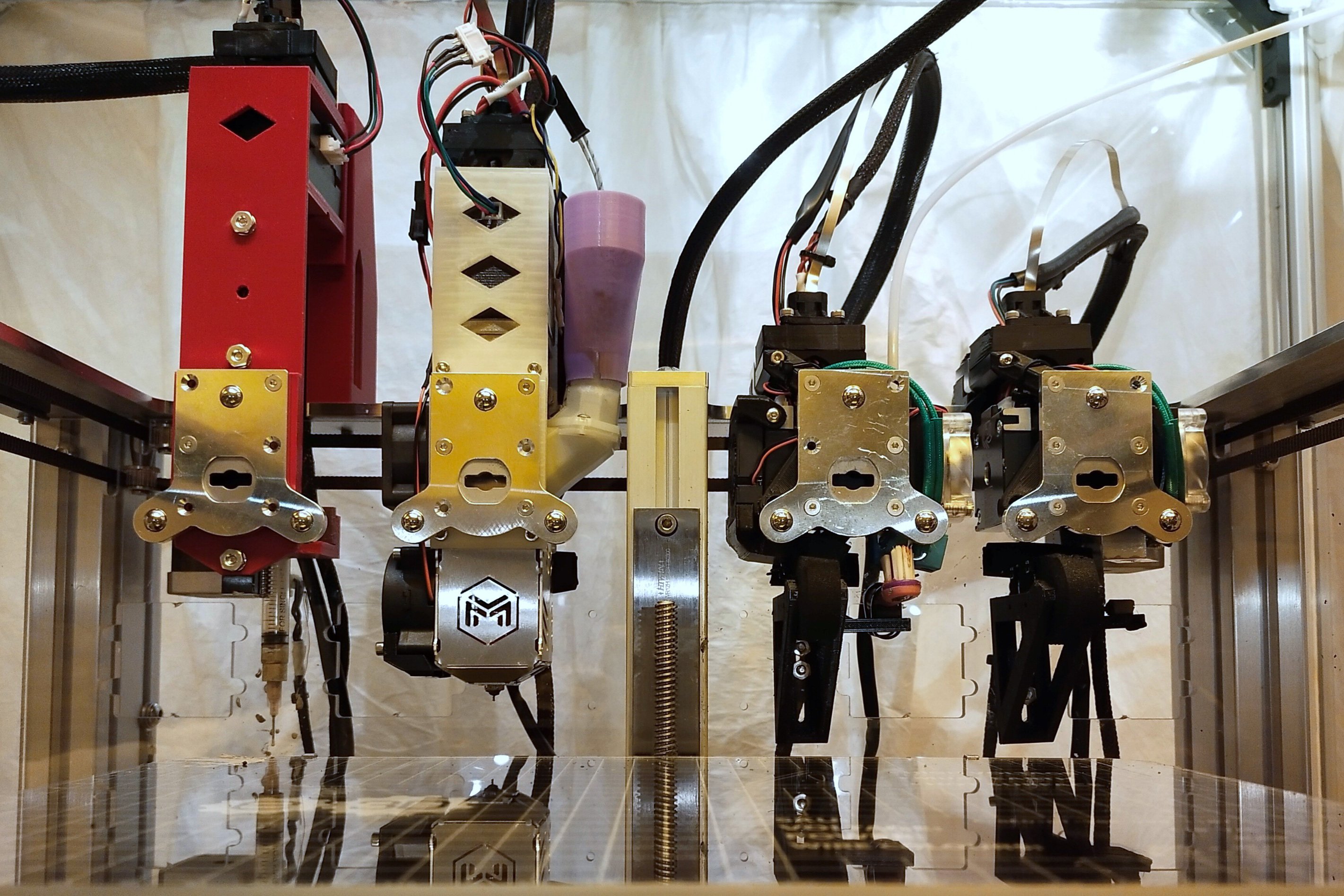

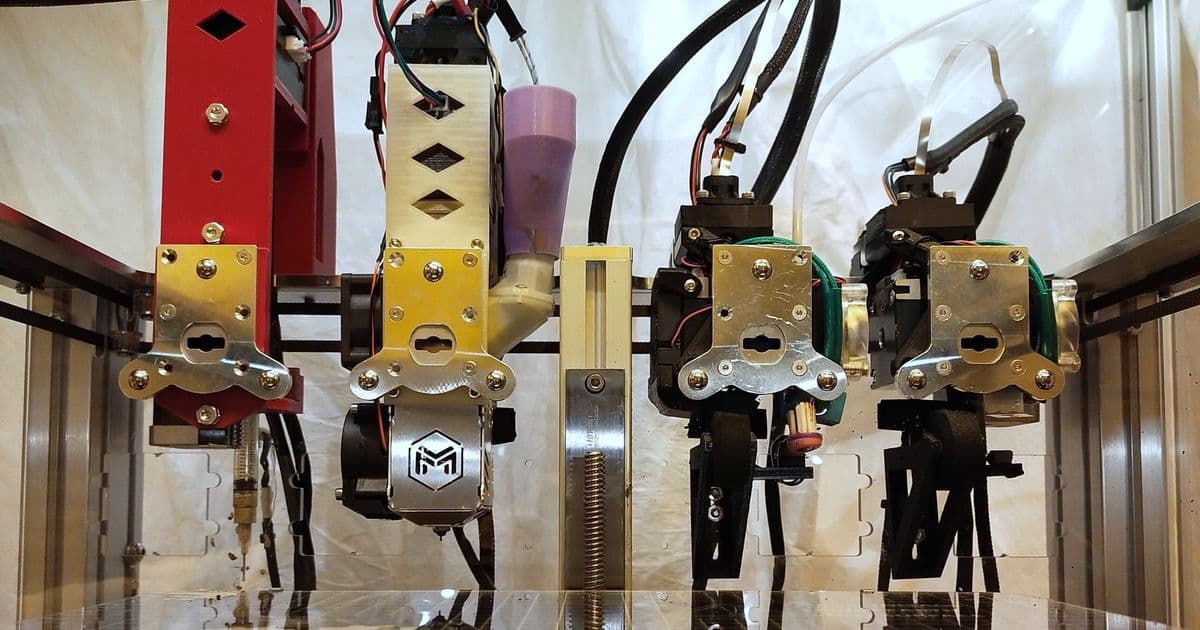

Engineering a Multimaterial Solution The key innovation lies in the platform's ability to handle four different extrusion tools, each designed for a specific form of printable material. Unlike conventional multimaterial extrusion 3D printing systems that can only switch between two materials in the same form (such as filament or pellets), the MIT team's system accommodates varied material expressions.

Each extruder was carefully engineered to balance material requirements and limitations. For instance, the electrically conductive material—which must harden without excessive heat or UV light that could degrade dielectric materials—comes in ink form and requires a pressure-based extrusion system. This approach has vastly different requirements than standard heated nozzle systems used for melted filament or pellets.

To ensure precision, the researchers implemented strategically placed sensors and a novel control framework. This system guarantees that each tool is picked up and put down consistently by the platform's robotic arms, and that each nozzle moves precisely and predictably. Even slight misalignments could derail the performance of the finished machine, making this level of control critical.

From Concept to Functional Motor The researchers demonstrated their platform's capabilities by fabricating a fully functional electric linear motor in approximately three hours using five different materials. The only post-processing step required was magnetizing the hard magnetic materials to enable full functionality.

Linear motors, which generate straight-line motion rather than rotation, are used in applications ranging from pick-and-place robotics and optical systems to baggage conveyors. The 3D-printed motor achieved several times more actuation than a common type of linear engine that relies on complex hydraulic amplifiers.

With material costs estimated at about 50 cents per device, the economic advantages are significant. The ability to produce these motors on-site could eliminate supply chain dependencies and reduce waste, particularly valuable for industries requiring customized electronic components for robots, vehicles, or medical equipment.

Technical Challenges and Solutions The development process involved overcoming significant engineering challenges. "We had to figure out how to marry together many different expressions of the same printing method—extrusion—seamlessly into one platform," Velásquez-García explains.

The team, which included electrical engineering and computer science graduate students Jorge Cañada (lead author) and Zoey Bigelow, focused on extrusion 3D printing—a reliable method that involves depositing material through a nozzle to build objects layer by layer. Their innovation was making this method work with multiple functional materials that offer different capabilities within the same device.

Future Applications and Development While the electric linear motor serves as a compelling demonstration, the researchers view it as just the beginning. The platform opens possibilities for manufacturing a wide range of electronic devices on-site in a single step.

Future development plans include integrating the magnetization step into the multimaterial extrusion process itself, demonstrating the fabrication of fully 3D-printed rotary electrical motors, and adding more tools to the platform to enable monolithic fabrication of increasingly complex electronic devices.

The research, funded in part by Empiriko Corporation and the La Caixa Foundation, represents a significant step toward democratizing the manufacturing of complex devices. By reducing dependence on specialized manufacturing centers and global supply chains, this technology could enable rapid prototyping, customization, and on-demand production of electronic components across multiple industries.

As Velásquez-García notes, "Even though we are excited by this engine and its performance, we are equally inspired because this is just an example of so many other things to come that could dramatically change how electronics are manufactured."

The implications extend beyond manufacturing efficiency. This technology could enable new approaches to hardware development, support distributed manufacturing models, and reduce the environmental impact associated with traditional electronics production and global shipping networks. As the platform evolves to handle even more complex devices, it may fundamentally reshape how we think about producing the electronic components that power our modern world.

Comments

Please log in or register to join the discussion