Adding intelligent audio feedback to an analog radiation meter transforms it into a practical tool for field geology.

The Ludlum Model 3 radiation meter offers reliability and versatility for detecting ionizing radiation, but its analog design presents challenges for rock collectors. While its adjustable high-voltage supply accommodates various detectors like Geiger-Müller tubes or scintillators, the high background radiation captured by scintillation detectors renders traditional audio clicks useless. This forces users to constantly watch the needle instead of focusing on terrain navigation.

The Audio Limitation Problem

Scintillation detectors register hundreds of background counts per second, drowning out subtle signals from interesting minerals. Standard click dividers (triggering audio every 16-32 pulses) help somewhat but fail to distinguish faint anomalies buried in statistical noise. Human ears struggle to notice if one click arrives slightly earlier than expected; computers excel at this temporal discrimination.

Circuit Modification

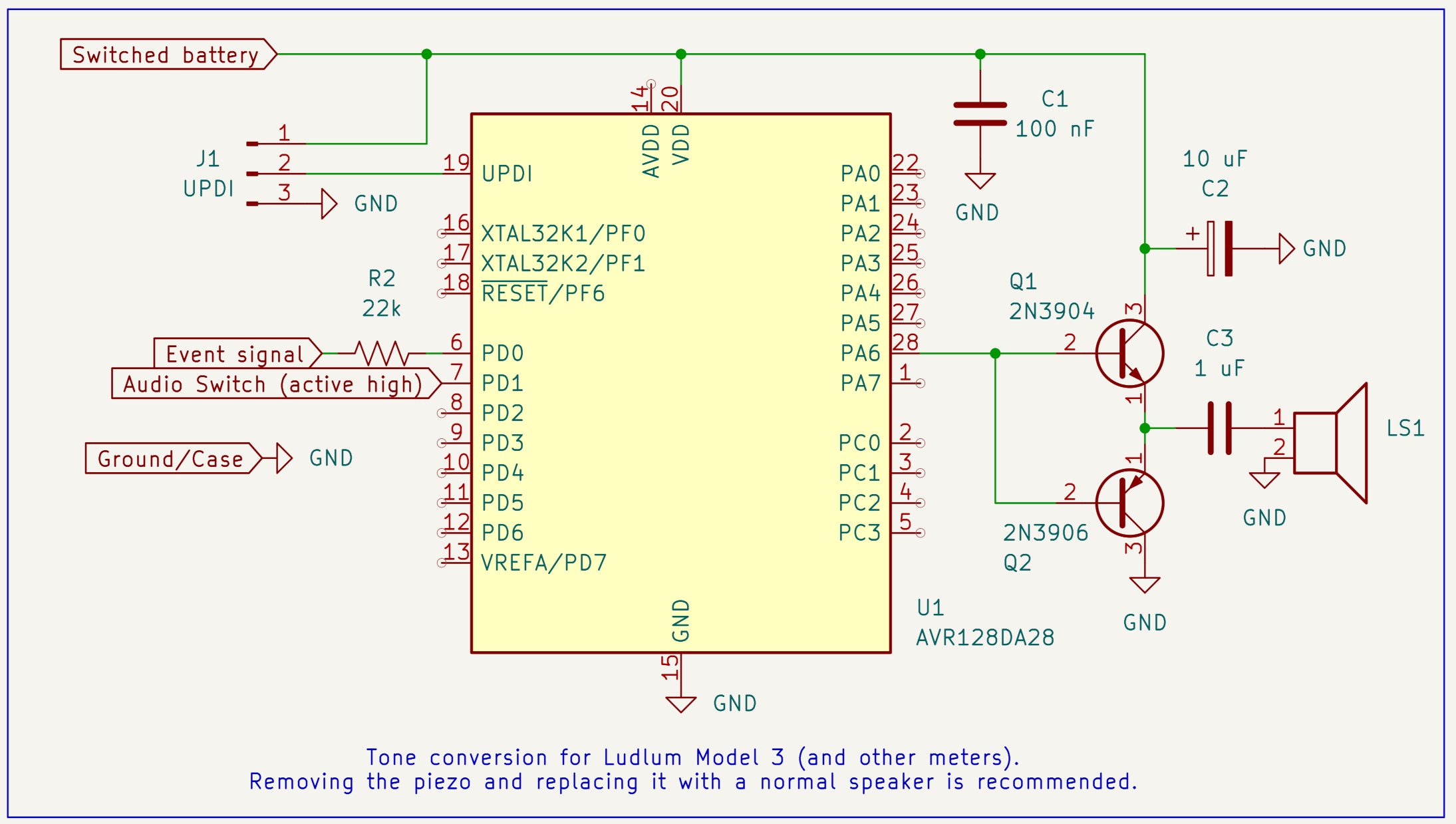

The solution replaces passive audio with an ATtiny microcontroller programmed to process counts intelligently. The circuit:

- Measures current count rates using a half-second sliding window

- Subtracts baseline background radiation captured during a 3-second startup calibration

- Generates variable-pitch tones only when counts significantly exceed background

Power comes from the meter's reset button (switch-controlled), while the event signal connects to pin 3 of the CD4093BE IC. Since this IC uses 7V logic, a 22k series resistor protects the microcontroller. Note: Ludlum Model 3 revisions vary, so consult your schematic or probe signals with an oscilloscope.

Schematic: Microcontroller interface replacing analog audio circuit

Schematic: Microcontroller interface replacing analog audio circuit

Installation and Safety

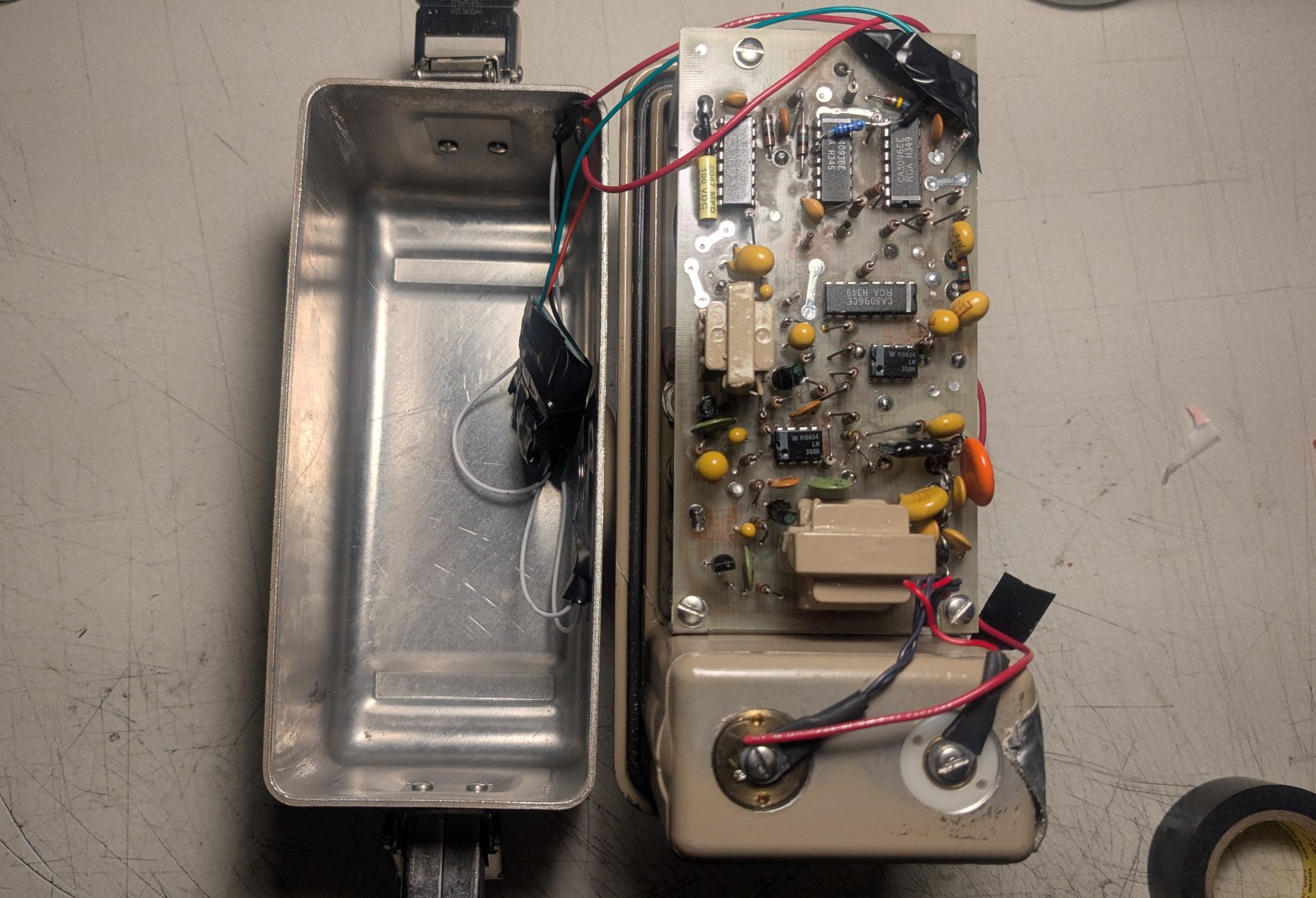

The microcontroller fits inside the case near the main board. Critical precautions:

- Wrap the microcontroller in insulating tape to prevent shorts

- Route wires away from high-voltage components (>500V)

- Secure the board with tape to avoid contact with transformers

- Keep wiring minimal to reduce induction risk

Internal view showing secured microcontroller installation

Internal view showing secured microcontroller installation

Field Performance

Testing revealed unexpected sensitivity:

- Detected Utah sandstone (30 µSv/h contact dose) from 80 cm away

- Identified deep ore veins and soil contamination through ground penetration

Differentiate sources by radiation profile: point sources (rocks) show intense hotspots with rapid falloff, while diffuse contamination produces uniform fields. Verify by lifting the meter 15 cm—point sources diminish noticeably.

Operational Workflow

- Power on: Meter beeps once

- 3-second calibration: Measures background

- Ready beep: Begins monitoring

- Audio activates only when counts exceed background + threshold

- Follow increasing pitch to locate sources

Troubleshooting

- No audio: Verify microcontroller power/programming

- 10 beeps post-calibration: No counts detected (check probe)

- Constant noise: Background higher than calibration (power-cycle)

- Random screaming/needle spikes: Loose cable/connector

Limitations

Requires detectors with >30 counts/second background. Less sensitive units (e.g., Raysid, Better Geiger) won't provide sufficient signal. For budget options, seek used scintillators—1.25"×1.25"×3" NaI(Tl) crystals work well.

Source Implementation

Code (tone.c) and compiled firmware (tone.elf) available. Programming requires a UPDI interface: improvise with USB-UART adapter (1k resistor between Tx/Rx, connect Rx to UPDI pin). Atmel ICE users may need firmware updates.

This modification transforms a vintage instrument into a functional field tool, demonstrating how targeted electronics upgrades can breathe new life into analog devices.

Comments

Please log in or register to join the discussion