Researchers at Fudan University have developed a flexible fiber integrated circuit (FIC) thinner than a human hair that packs 100,000 transistors per centimeter and can withstand crushing forces of 15.6 tons, potentially revolutionizing wearable electronics and brain-computer interfaces.

A team of researchers from Fudan University in Shanghai has achieved a breakthrough in flexible electronics by creating a computer chip embedded in a fiber thinner than a human hair that can process information like a traditional computer while withstanding extreme physical stress.

The Fiber Integrated Circuit (FIC) represents a significant leap forward in flexible electronics technology. Unlike current flexible devices that still rely on rigid silicon components, this innovation integrates all circuitry directly into a flexible fiber structure that can be stretched, twisted, and woven into everyday clothing.

The Sushi Roll Inspiration

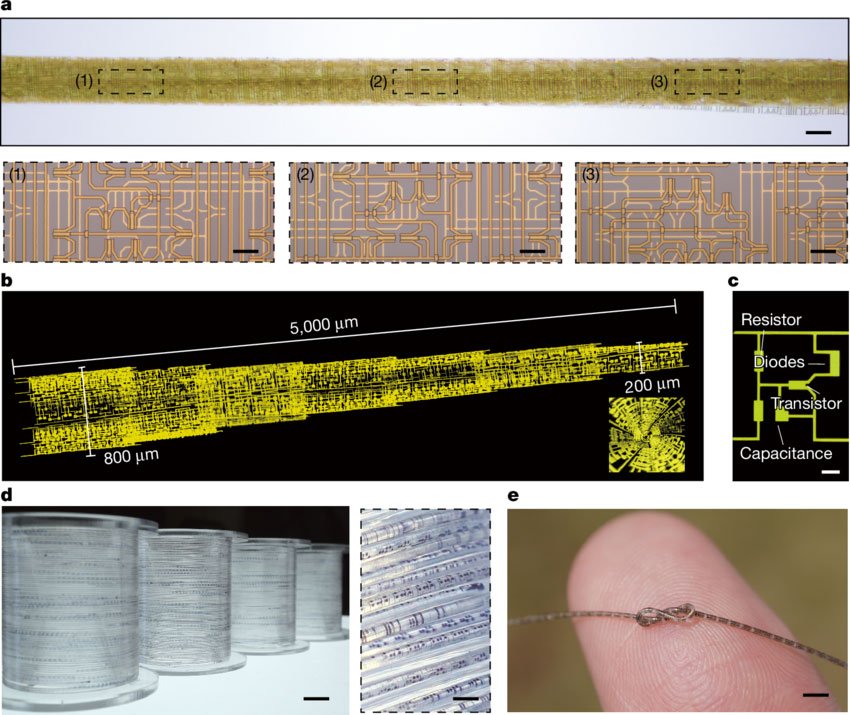

The researchers drew inspiration from an unlikely source: the construction of a sushi roll. By building complex electronic circuits in thin layers on flexible substrates and then rolling them up tightly, they created what they describe as a "multilayered spiral architecture." This approach allows for unprecedented integration density while maintaining flexibility.

The finished fiber measures approximately 50 micrometers in diameter—thinner than an average human hair—yet packs an impressive 100,000 transistors per centimeter. This density enables digital and analog signal processing capabilities comparable to typical commercial arithmetic chips, with the researchers claiming it's sufficient for "high-recognition-accuracy neural computing."

Durability That Defies Belief

Perhaps most remarkably, the FIC demonstrates extraordinary durability. The research paper published in Nature reports that the fiber can withstand:

- 10,000 cycles of repeated bending and abrasion

- Stretching up to 30% of its original length

- Twisting at angles of 180 degrees per centimeter

- Crushing forces equivalent to a 15.6-ton container truck

The researchers even documented their testing by parking a truck on one of the FIC test fibers, demonstrating the material's resilience under extreme conditions.

Processing Power in a Fiber

While the researchers' blog post claims that a 1-meter fiber "could hold millions of transistors, reaching the power levels of a standard desktop computer processor," this comparison requires context. To put this in perspective, achieving millions of transistors would place this technology in the range of late 1990s processors like the Intel Pentium III or AMD K6-2, which each featured just under 10 million transistors.

Despite not matching modern multi-billion transistor processors, the FIC's density is sufficient for practical applications requiring in-fiber digital and analog signal processing.

Mass Production and Future Applications

The Chinese research team has already identified a viable method for mass-producing these FICs, suggesting the technology could move beyond the laboratory relatively quickly. They foresee several key applications:

Brain-Computer Interfaces: The FIC's extreme thinness and flexibility make it particularly suitable for interfacing with brain tissue. The researchers note that the fibers are "as flexible as brain tissue," potentially enabling more comfortable and effective neural interfaces.

Virtual Reality: The team envisions VR gloves made with FIC technology that would be "indistinguishable from ordinary fabric" while providing sophisticated sensing and processing capabilities.

Smart Textiles: The ability to weave these fibers into clothing opens up possibilities for garments with embedded computing capabilities, from health monitoring to interactive displays.

The Evolution of Flexible Electronics

Flexible electronics have made significant strides in recent years, with malleable components for power, sensing, and display becoming increasingly available. However, most "flexible" devices still contain rigid silicon wafer components that limit their applications and comfort.

The Fudan team's approach of creating a truly integrated flexible circuit could remove the "last vestiges of electronic rigidity" from wearable devices, potentially enabling a new generation of comfortable, durable, and capable flexible electronics.

This breakthrough represents a convergence of materials science, semiconductor engineering, and creative problem-solving. By reimagining how circuits can be constructed and packaged, the Shanghai researchers have created a technology that could fundamentally change how we think about wearable computing and flexible electronics.

As the technology moves toward commercialization, it will be interesting to see how device manufacturers incorporate these ultra-thin, ultra-durable fibers into next-generation products, potentially bringing science fiction concepts like smart clothing and advanced neural interfaces closer to reality.

Comments

Please log in or register to join the discussion