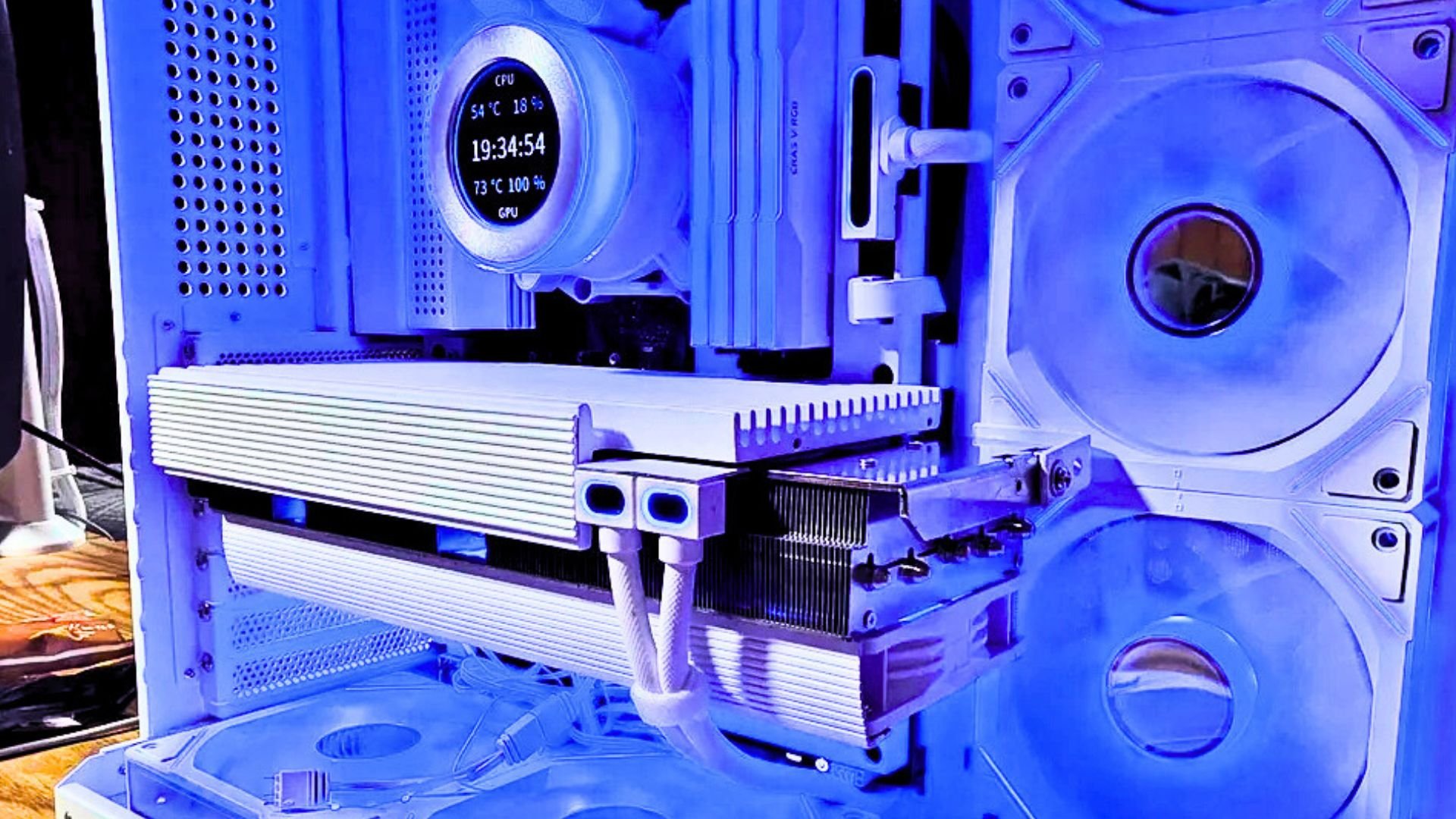

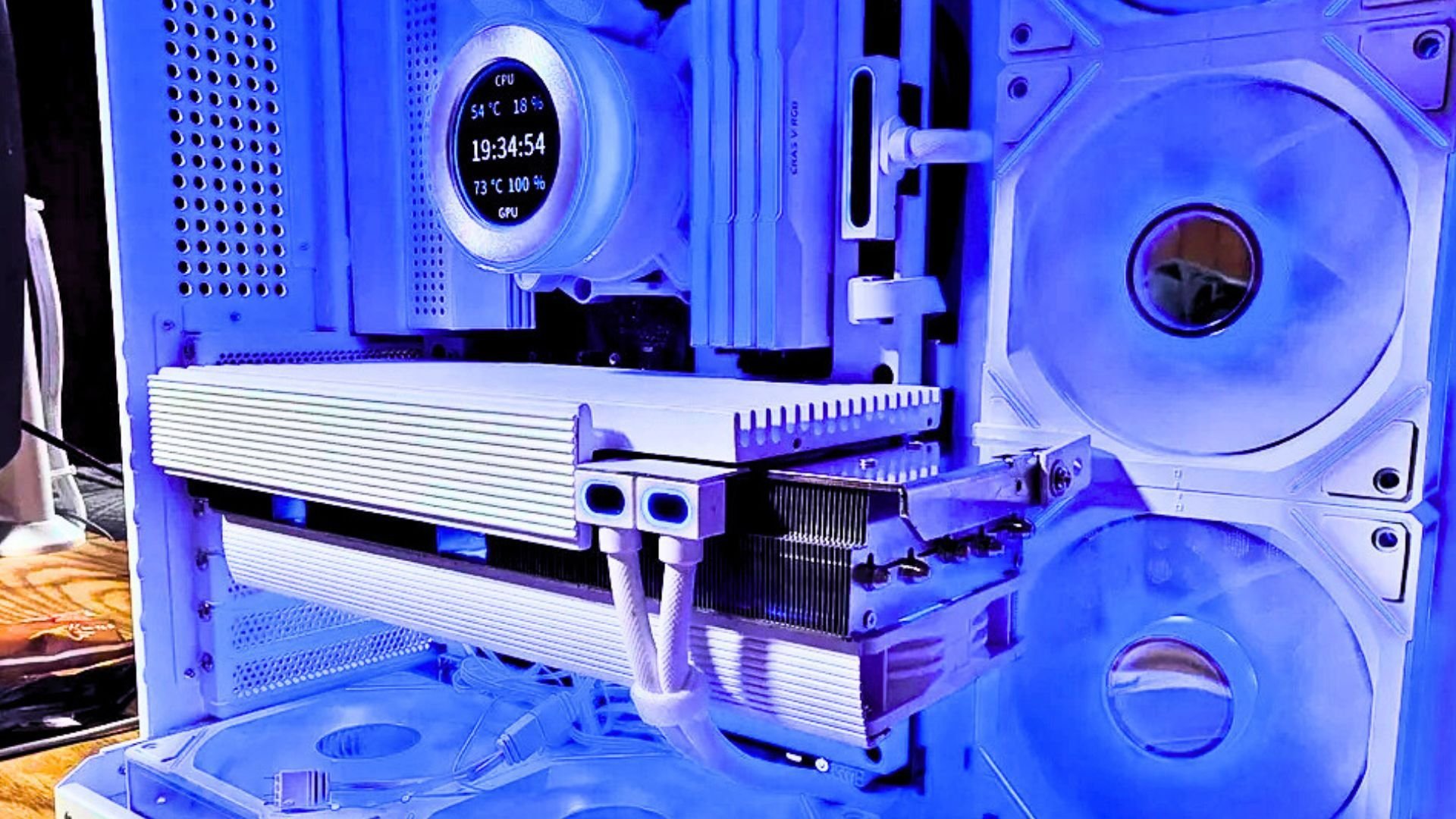

A Reddit user transformed an old MSI RTX 3080 Ventus by repurposing a 100-watt car amplifier heatsink, achieving a 10°C reduction in GPU temperatures and a striking white aesthetic. The mod highlights the ongoing thermal challenges of high-end GPUs and the creative lengths enthusiasts go to extend hardware lifespans.

A Redditor known as ComplexSupermarket89 has engineered an unconventional cooling solution for an aging MSI RTX 3080 Ventus graphics card, repurposing a 100-watt car amplifier heatsink to achieve a significant temperature reduction. The project, shared on Reddit, demonstrates how DIY enthusiasts are tackling thermal limitations in older high-performance GPUs through creative material reuse and custom fabrication.

The mod was born out of necessity. The user's RTX 3080, once considered one of the best graphics cards available, began experiencing critical thermal issues, with memory and hotspot temperatures reaching 102°C and 105°C respectively. After attempting a conventional fix by repadding the card, the overheating problem resurfaced within a year, prompting a more radical approach.

The Thermal Challenge of the RTX 30 Series

The RTX 3080, built on Samsung's 8nm process node, represents a significant thermal design challenge. The card's 28.3 billion transistors and 320W TDP create substantial heat density, particularly in the memory subsystem. The GDDR6X memory modules, which operate at 19 Gbps, generate considerable heat under load, and the original Ventus cooler—designed for cost-effectiveness rather than peak performance—struggles to dissipate this thermal load over time.

Thermal pad degradation is a common issue with these cards. The original pads, typically made from silicone or graphite composites, can lose their compressibility and thermal conductivity after repeated thermal cycling. This creates air gaps between the memory chips and the heatsink, drastically reducing heat transfer efficiency. The user's initial repadding attempt provided temporary relief, but the underlying thermal design limitations remained.

The Car Amplifier Solution

The DIYer's breakthrough came from an unlikely source: a discarded 100-watt car amplifier. These amplifiers typically feature massive aluminum heatsinks designed to dissipate heat from power transistors during high-current operation. The thermal mass and surface area of these heatsinks often exceed those of entry-level GPU coolers.

The modification process involved several precise steps:

Material Preparation: The user cut the amplifier heatsink to match the RTX 3080's PCB dimensions, ensuring proper coverage of the GPU die, memory chips, and power delivery components.

Electrical Isolation: Polyimide tape (Kapton tape) was applied to cover potential short points, a critical safety measure when mounting metal components directly to a PCB.

Thermal Interface Enhancement: The user applied Arctic MX-7 thermal paste between the memory chips and the new heatsink, replacing the original thermal pads. MX-7 is a high-performance paste with a thermal conductivity rating of 9-10 W/mK, significantly better than standard thermal pads (typically 1-3 W/mK).

Aesthetic Finishing: The original black powder-coated finish was sanded down and repainted with white high-temperature engine enamel, creating a cohesive white aesthetic.

Custom Cooling Architecture

Beyond the primary heatsink, the mod includes a comprehensive cooling system redesign:

Custom Fan Shroud: Fabricated from scrap aluminum, the shroud houses three 92mm Thermalright RGB fans, replacing the stock fans. The front section mounts to the original GPU heatsink, while the rear attaches to the custom heatsink via steel brackets.

Structural Support: The added aluminum mass exceeds 3 pounds, necessitating a 90-degree steel bracket to prevent PCIe slot damage and GPU sag. This is a common issue with heavy aftermarket coolers, as the PCIe slot can only support approximately 1.5 pounds of weight before mechanical stress becomes a concern.

Thermal Monitoring: The user reports that while GPU core temperatures dropped by 10°C, memory junction temperatures still reach 96-98°C under load. The large thermal mass provides a slower temperature ramp, but sustained loads still push the limits of the cooling solution.

Performance and Practical Implications

The results demonstrate the effectiveness of brute-force thermal mass. The GPU hotspot temperature dropped by at least 20°C, while overall GPU temperatures decreased by 10°C. This is significant for an RTX 3080, where thermal throttling typically begins around 83°C for the core and 100°C for memory.

However, the solution isn't without trade-offs:

Weight and Mechanical Stress: The 3+ pound assembly requires additional structural support, complicating installation and potentially affecting case compatibility.

Aesthetics vs. Function: The white finish looks "absolutely stunning" according to the user, but the paint adds a thin insulating layer that slightly reduces thermal conductivity.

Future-Proofing: The user acknowledges the RTX 30-series is aging, planning to upgrade to the next AMD flagship. The mod represents a "passion project" rather than a long-term solution.

Broader Context: GPU Thermal Management

This project reflects a broader trend in GPU cooling. As manufacturers push performance boundaries, thermal solutions become increasingly critical. The RTX 3080's thermal challenges are well-documented, with many users experiencing similar issues after 2-3 years of use.

Third-party cooling solutions, from AIO liquid coolers to massive air heatsinks, have proliferated. However, the car amplifier approach is unique in its material reuse and cost-effectiveness. A new 100-watt amplifier heatsink might cost $20-30, compared to $100+ for commercial GPU coolers.

The mod also highlights the limitations of stock coolers on mid-range AIB (add-in board) models like the Ventus. These cards prioritize cost over thermal headroom, leading to higher operating temperatures and potential long-term reliability issues.

Technical Considerations for DIY Modders

For those considering similar modifications, several factors warrant attention:

Material Compatibility: Aluminum heatsinks must be electrically isolated from PCB traces. Polyimide tape is essential, but thermal epoxy can provide a more permanent solution.

Thermal Interface Material Selection: For memory chips, thermal pads are often preferable to paste due to gap-filling requirements. The user's choice of MX-7 paste for memory may not be optimal long-term, as paste can pump out under repeated thermal cycling.

Structural Engineering: Heavy coolers require reinforced mounting. The 90-degree bracket is a smart addition, but case compatibility must be verified.

Airflow Considerations: The custom shroud must align with case airflow patterns. The three 92mm fans provide adequate static pressure, but their effectiveness depends on proper orientation and case ventilation.

The Future of GPU Cooling

This project underscores a growing reality: as GPU power consumption increases (the RTX 3080 at 320W is modest compared to the RTX 4090's 450W), stock coolers may become inadequate over time. Thermal paste degradation, pad compression, and dust accumulation compound these issues.

Manufacturers are responding with improved designs. The RTX 40-series features larger coolers and better thermal interfaces, but the fundamental challenge remains: dissipating hundreds of watts from a small die area.

For enthusiasts, DIY solutions like this car amplifier mod represent both practical necessity and creative expression. While not everyone has access to aluminum scrap or fabrication tools, the principles—maximizing thermal mass, improving interface materials, and ensuring structural integrity—are universally applicable.

Conclusion

ComplexSupermarket89's RTX 3080 mod is a testament to ingenuity in hardware modification. By repurposing a car amplifier heatsink, the user achieved a 10°C temperature reduction, extending the card's usable life while creating a visually striking custom design. The project highlights the thermal challenges of high-performance GPUs and the creative solutions enthusiasts develop to address them.

For those facing similar thermal issues with aging RTX 30-series cards, this approach offers a cost-effective alternative to commercial coolers. However, it requires careful planning, proper tools, and attention to structural and electrical safety. As the user notes, it's a "labor of love"—a sentiment that resonates deeply within the PC modding community.

The full project details and images are available on the original Reddit post, where ComplexSupermarket89 continues to refine the design and consider additional improvements, including a recessed fan for the custom heatsink.

Jowi Morales is a contributing writer with extensive experience in tech hardware and consumer electronics, covering GPU technology and thermal solutions since 2021.

Comments

Please log in or register to join the discussion