Researchers at Hiroshima University have developed a novel 3D printing technique that softens rather than melts tungsten carbide-cobalt, enabling the additive manufacturing of one of the world's hardest materials while maintaining exceptional hardness and reducing waste.

Scientists at Hiroshima University have achieved a significant breakthrough in additive manufacturing by developing a novel technique to 3D print tungsten carbide-cobalt (WC-Co), one of the hardest engineering materials used in industry today. This advancement addresses a long-standing challenge in manufacturing, as ultra-hard materials like WC-Co have traditionally been extremely difficult to process using additive methods due to their exceptional hardness and high melting points.

The Challenge of Ultra-Hard Materials

Tungsten carbide-cobalt composites are prized in industrial applications for their remarkable hardness, wear resistance, and strength. These properties make them ideal for cutting tools, mining equipment, and wear-resistant components in construction machinery. However, the very characteristics that make WC-Co valuable also make it notoriously difficult to manufacture using conventional methods.

Traditional subtractive manufacturing of WC-Co involves extensive machining, which generates significant material waste and requires specialized equipment capable of cutting through one of the hardest materials known. The material's extreme hardness, typically exceeding 1400 HV (Vickers hardness), means that standard cutting tools quickly wear out, making the manufacturing process both expensive and inefficient.

The Hot-Wire Irradiation Method

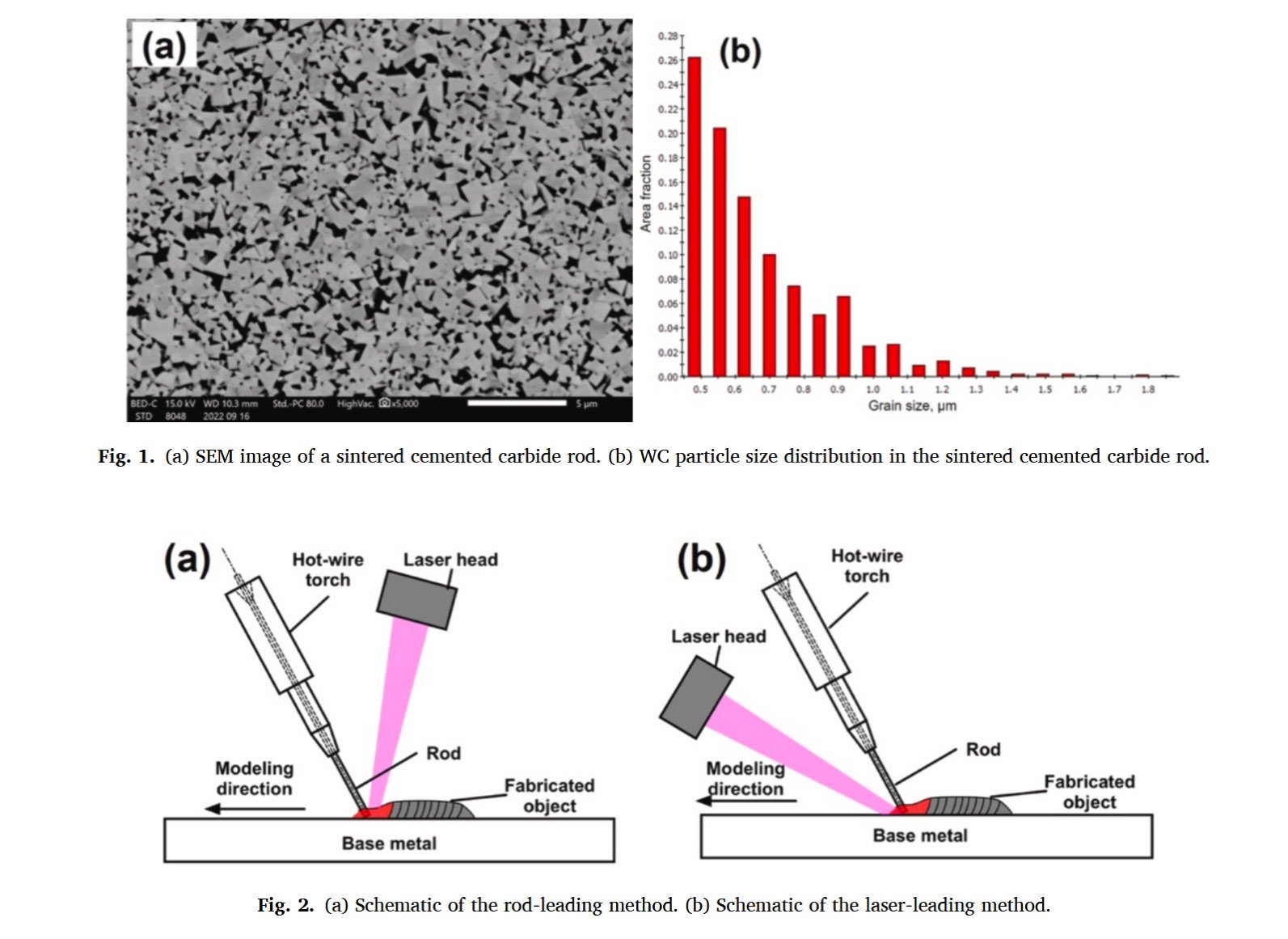

The Hiroshima University research team, led by Assistant Professor Keita Marumoto from the Graduate School of Advanced Science and Engineering, developed what they call a "hot-wire irradiation method" to overcome these manufacturing challenges. This innovative approach uses laser hot-wire welding technology to soften the cemented carbide rod rather than fully melting it during the additive manufacturing process.

In this technique, a laser beam precisely heats the WC-Co material to a temperature that softens it without reaching its melting point. This controlled heating prevents grain growth that typically occurs during full melting, which can compromise the material's structural integrity and hardness. By maintaining the material in a softened state rather than a fully molten one, the researchers were able to build up additive structures layer by layer while preserving the material's exceptional properties.

Process Refinements and Results

The research team discovered that inserting a nickel alloy-based middle layer between additive layers significantly improved the quality and consistency of the 3D printed structures. This intermediate layer helps manage thermal stresses and improves layer adhesion, resulting in more reliable and defect-free components.

The results of this novel manufacturing approach are impressive. The 3D printed WC-Co material achieved a hardness of over 1400 HV, maintaining its exceptional hardness without introducing defects or decomposition. This hardness level places the material just below super-hard materials like sapphire and diamond, making it one of the hardest 3D printed materials ever produced.

Environmental and Economic Benefits

Beyond the technical achievement, the Hiroshima University team emphasizes the environmental advantages of their approach. Traditional manufacturing methods for WC-Co generate substantial material waste through machining processes. The additive manufacturing technique developed by the researchers significantly reduces this waste, as material is only deposited where needed, rather than being cut away from larger blocks.

This reduction in waste not only benefits the environment but also improves the economic viability of manufacturing with ultra-hard materials. The cost savings from reduced material waste, combined with the elimination of expensive specialized cutting tools, could make WC-Co components more accessible for a wider range of applications.

Future Developments and Applications

The research team, which includes Takashi Abe, Keigo Nagamori, Hiroshi Ichikawa, Akio Nishiyama, and Motomichi Yamamoto, is already working on refining the process further. Current efforts focus on addressing cracking issues that have been observed in some printed structures and developing the capability to create more complex geometries.

Looking ahead, the implications of this technology extend beyond just WC-Co. As Assistant Professor Marumoto noted, "The approach of forming metal materials by softening them rather than fully melting them is novel, and it has the potential to be applied not only to cemented carbides, which were the focus of this study, but also to other materials."

This suggests that the hot-wire irradiation method could potentially be adapted for other ultra-hard or difficult-to-process materials, opening up new possibilities in additive manufacturing across various industries.

The Broader Context of Metal 3D Printing

This breakthrough comes at a time when metal 3D printing is rapidly evolving, though it remains significantly more challenging than plastic-based additive manufacturing. Metallic alloys require extreme temperatures, often exceeding 1000°C, and undergo complex thermal cycles and phase changes during processing. These factors make metal 3D printing more technically demanding and expensive than its plastic counterparts.

The ability to successfully 3D print materials like WC-Co represents a significant step forward in expanding the range of materials available for additive manufacturing. As the technology matures and becomes more accessible, it could revolutionize how industries approach the design and manufacturing of wear-resistant and high-performance components.

The research from Hiroshima University demonstrates how innovative approaches to material processing can overcome seemingly insurmountable manufacturing challenges. By thinking beyond traditional melting-based additive manufacturing and developing the hot-wire irradiation method, the team has opened new possibilities for working with some of the hardest materials known to engineering.

As this technology continues to develop, it may lead to more sustainable, efficient, and cost-effective manufacturing processes for ultra-hard materials, potentially transforming industries that rely on cutting tools, wear-resistant components, and other applications where material hardness is paramount.

Comments

Please log in or register to join the discussion