The Bambu Lab H2C introduces a novel Vortek system that assigns dedicated nozzles to filament colors, virtually eliminating purge waste and cutting multicolor print times in half compared to the H2D. However, its $2,399 price tag and mechanical complexity place it in an awkward middle ground between standard AMS printers and true tool changers like the Prusa XL.

The Bambu Lab H2C arrives as the company's answer to one of multicolor 3D printing's most persistent problems: filament waste. Traditional systems like Bambu's own AMS purge old material through the nozzle during color changes, creating what's colloquially called "filament poop"—a necessary byproduct that can waste hundreds of grams of material on complex prints. The H2C's Vortek Hotend Changer eliminates this waste by assigning each color its own dedicated nozzle, but stops short of delivering a true tool changing system.

The Vortek System: Engineering Around Waste

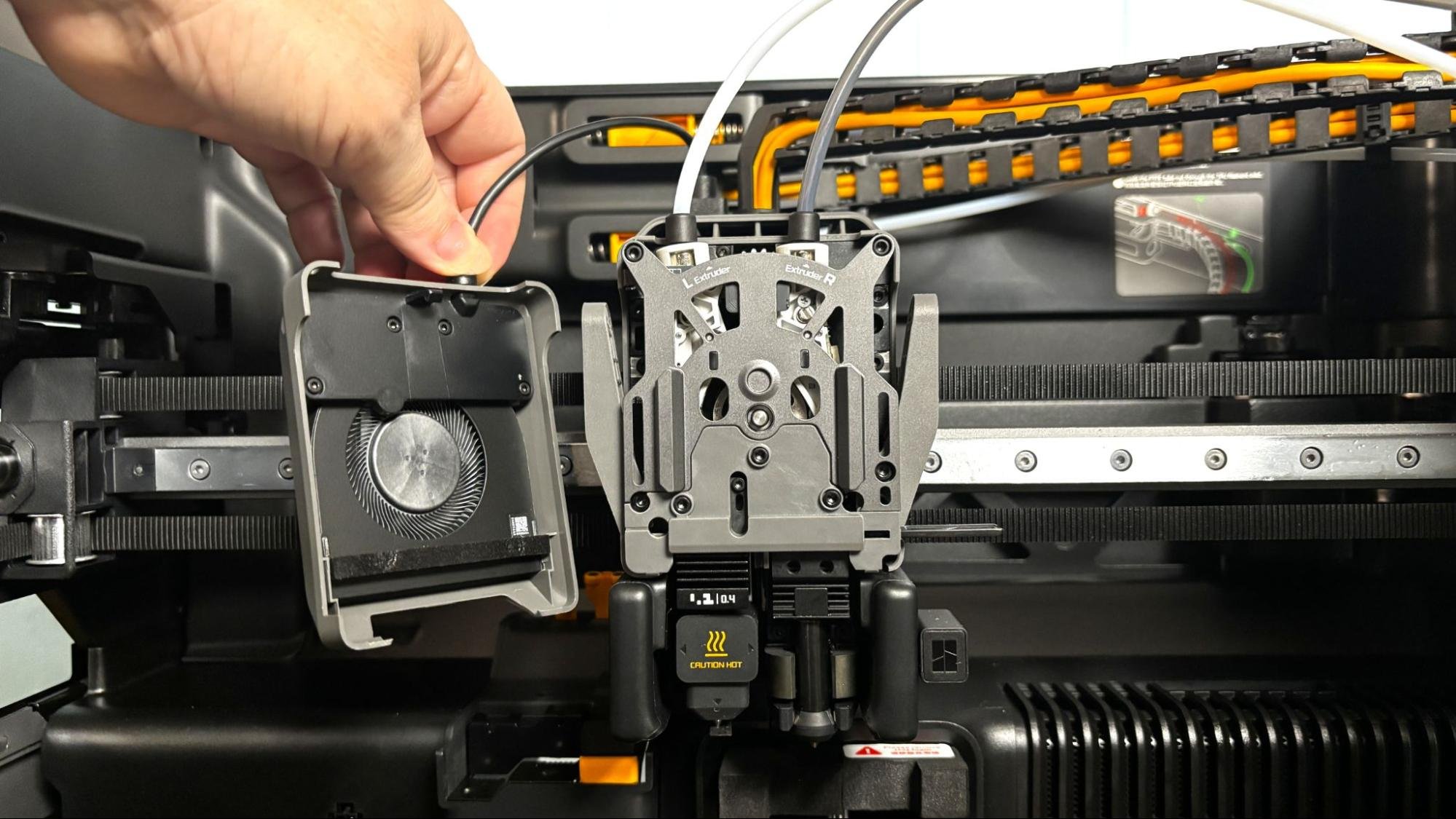

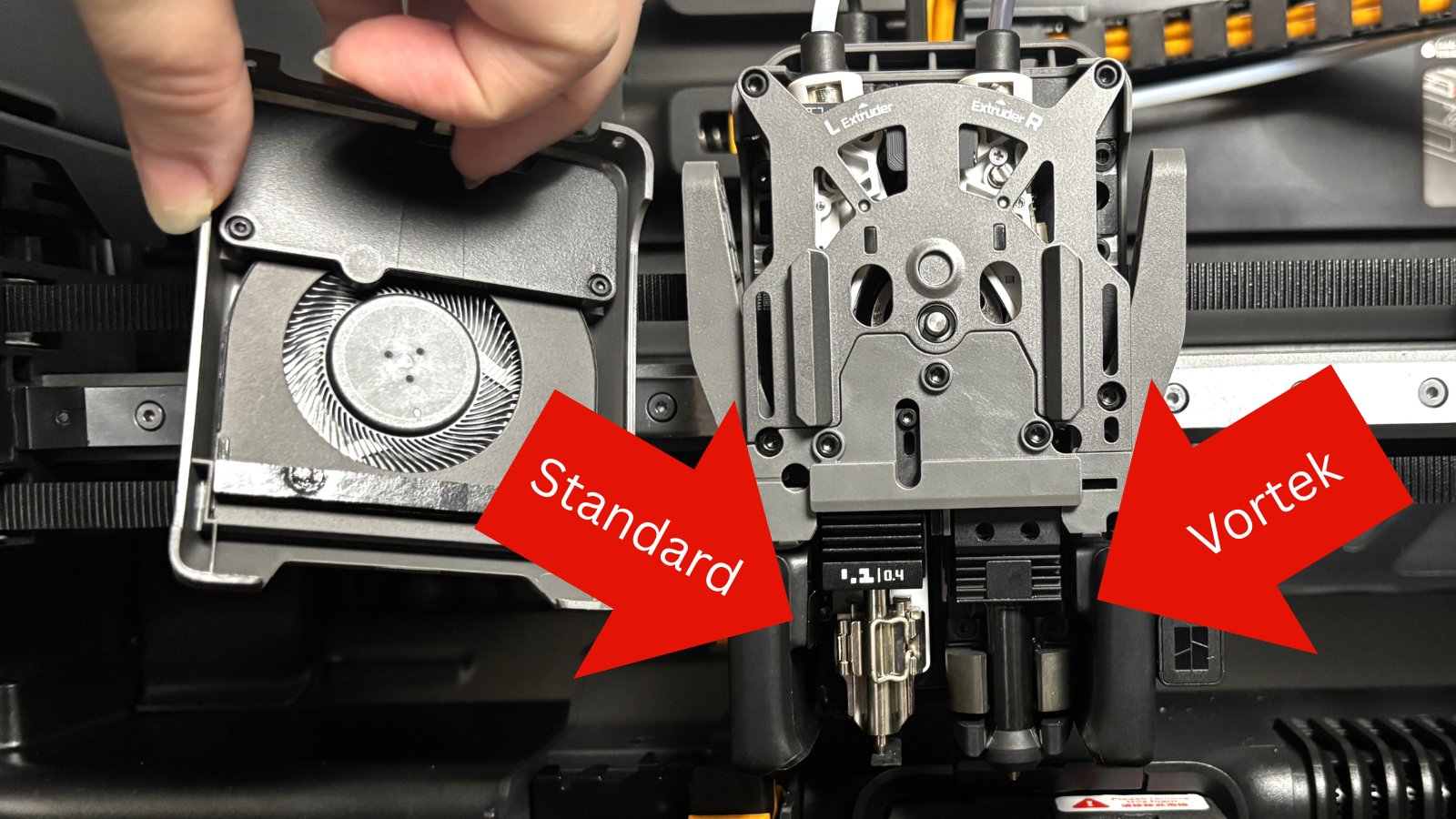

The core innovation in the H2C is the Vortek rack, which holds up to six induction-heating nozzles on the right side of the build chamber. These cylindrical nozzles use contactless interfaces and heat from room temperature to printing temperature in just eight seconds. The tool head can autonomously grasp and swap these nozzles without human intervention, placing them back on the magnetic rack when not in use.

This design creates a hybrid approach to multicolor printing. The H2C retains the dual-nozzle tool head from the H2D—one standard H2 nozzle on the left, and the Vortek-capable system on the right. When purchased as a combo, the printer includes a four-spool AMS 2 Pro, giving you five total filament sources (one on the left, four on the right via Vortek). Adding a second AMS to the right side fills all six Vortek nozzles for seven-color printing without waste.

The system works by eliminating the need for purging. Since each color maintains its own nozzle, there's no old material to clear out. Bambu Lab claims this cuts color swap time in half compared to their other AMS-equipped printers. In our testing, a five-color print that took 23.5 hours on the H2D completed in just 11 hours and 13 minutes on the H2C, with only a 41g prime tower compared to 279g of total waste on the H2D.

Not a True Tool Changer

Despite its capabilities, the H2C doesn't qualify as a true tool changer. Systems like the Prusa XL or Snapmaker U1 give each filament its own complete tool head with extruder, motor, and nozzle. This allows sub-second color changes since the filament never leaves the hotend. The H2C still requires the tool head to physically move to the rack, release one nozzle, pick up another, and return to printing—processes that take longer than a dedicated tool head would.

The Prusa XL completed our five-color calibration castle in just six hours, versus the H2C's 11 hours. While the H2C is dramatically faster than traditional AMS printers, it can't match the speed of a real tool changer.

The Vortek system also introduces mechanical complexity. Each nozzle contains wireless technology and induction heating elements priced at $39.99 for standard flow or $69.99 for high flow—$18-19 more than regular H2 nozzles. The tool head must precisely align with these nozzles, and the system needs many hours of testing to prove long-term reliability.

Hardware and Build Quality

The H2C shares the H2 lineup's premium construction: an aluminum and steel chassis with glass side panels, fully enclosed for high-temperature printing. The build volume measures 330 x 320 x 325 mm total, though dual-nozzle printing reduces this to 300 x 320 x 325 mm to accommodate the nozzle rack. The left nozzle can use the full build plate, while the right nozzle cannot reach the extreme left edge.

The printer includes three 1080p cameras: one for live monitoring, one on the nozzle for AI detection (spaghetti, air printing, clumping), and one on the tool head for calibration. The laser combo adds a fourth 8MP camera for material positioning. Automatic ventilation with intake and exhaust vents, plus a HEPA activated carbon filter, handles VOCs. An active chamber heater can boost internal temperature to 65°C, allowing the door to remain closed during PLA printing—a significant safety benefit for homes with children or pets.

AMS 2 Pro and Filament Management

The included AMS 2 Pro represents a significant upgrade over previous Bambu AMS units. It adds a heater capable of reaching 65°C for drying filament, with automatic vents that open during drying cycles to release moisture. During printing, the unit remains sealed with desiccant to maintain dry storage conditions.

The AMS HT is a separate single-spool unit that can heat to 85°C and includes a bypass for soft TPU or abrasive materials. However, the H2C presents a peculiar limitation: Bambu Lab recommends feeding TPU directly from the top into a dedicated Vortek nozzle, bypassing the AMS entirely. The left nozzle cannot accept TPU through the standard feed path, and the slicer actively prevents this configuration. This requires removing the AMS, glass lid, and using an elevated spool holder—significant friction for a material that many users print regularly.

Printing Performance

The H2C excels with PLA, ABS, and high-temperature materials. The closed enclosure and chamber heating make it capable of printing virtually anything with the door closed. Our test prints included:

- Speed Benchy: 16:37 in ludicrous mode, nearly perfect with minimal cooling issues on the bow

- Five-color calibration castle: 11:13 with 41g purge tower, compared to 23:30 and 279g waste on H2D

- PETG box: Seven hours total, smooth surfaces with excellent color transitions

- ASA dashboard hula girl: 19:39 for the upper half using five colors at 0.12mm layers

- TPU air tennis ball: 4:47 using Siraya Tech 95A PEBA, though supports proved problematic

The Vortek system uses a small prime tower only at print start to establish flow, not during color changes. This saves significant time and material. However, the slicer currently doesn't support mixing nozzle sizes on the same print, so you can't combine a 0.4mm and 0.6mm nozzle in one job.

Software and Usability

Bambu Studio received an overhaul for the H2D that benefits the H2C, with visual printer representations and improved AMS syncing. The interface shows the Vortek nozzle rack and allows filament mapping, though this process proved "janky" in testing and sometimes failed entirely.

The printer handles its own auto-leveling and vibration compensation, though the initial setup with dual nozzles takes 45 minutes. Once configured, bed leveling before each print is automatic and reliable.

Manual filament loading on the left side (without AMS) is tedious due to the short distance between spool holder and intake tube. The process requires confirming filament loading by peering into a tiny gap between nozzle and poop chute. It's far more practical to load a frequently-used color and leave it installed.

Market Position and Competition

At $2,399 for the H2C Combo, this printer sits in an awkward position. It's $400 more than the H2D and targets users who need large-format multicolor printing without the waste. However, the competition offers compelling alternatives:

- Creality K2 Plus: $1,199 on sale, larger Core XY with standard AMS

- Snapmaker U1: $849, four-color tool changer (smaller build volume)

- Prusa Research XL: True five-color tool changer, higher price but faster

- Upcoming INDX: Promises tool changing in 2026

The H2C makes sense for users who want Bambu Lab's ecosystem, premium features, and large build volume, and who prioritize waste reduction over absolute speed. It's also appealing for those who might want the laser/cutter capabilities available in the H2 lineup.

The Verdict

The Bambu Lab H2C successfully solves multicolor filament waste through clever overengineering. The Vortek Hotend Changer delivers on its promise of nearly waste-free printing while maintaining Bambu Lab's signature ease of use. However, it arrives at a time when true tool changers are becoming more accessible, making its premium price harder to justify.

The system's complexity—six induction-heating nozzles, autonomous swapping mechanisms, and proprietary parts—raises questions about long-term reliability and maintenance costs. Combined with TPU handling limitations and the need for manual left-nozzle loading, the H2C feels like a transitional product rather than a final solution.

For users with substantial budgets who need large-format multicolor printing and value waste reduction over speed, the H2C delivers. For everyone else, the Snapmaker U1 offers tool changing at half the price, and the Prusa XL remains the gold standard for serious multicolor work. Bambu Lab's engineering prowess is evident, but the H2C may be a stepping stone to something better rather than an endgame solution.

The printer is available now with a November 18, 2025 release date. Bambu Lab recommends purchasing a filament bundle, as no sample material was included with our review unit.

Specifications Summary

- Build Volume: 325 x 320 x 320 mm (single nozzle), 300 x 320 x 325 mm (dual nozzle)

- Materials: PLA/TPU/ABS/PPS up to 350°C

- Nozzle: 0.4mm proprietary (Vortek compatible)

- Bed: PEI textured spring steel, 120°C

- Footprint: 492 x 514 x 626 mm

- Weight: 32.5 kg

- Price: $2,399 (Combo)

- Cameras: Three 1080p + optional 8MP for laser

- Connectivity: WiFi, LAN, USB, 5" touchscreen

Comments

Please log in or register to join the discussion