Li Auto's i8 electric vehicle received a Top 10 New Energy Powertrain award in China for its fully in-house developed silicon carbide electric drive system, featuring industry-leading efficiency and cold-weather performance enhancements.

Li Auto's i8 SUV has been recognized as one of China's Top 10 New Energy Powertrain Systems at the 2026 'China Heart' Automotive Powertrain Conference. The core innovation is the vehicle's fully self-developed high-voltage silicon carbide (SiC) electric drive system, which achieved a peak efficiency rating of 93.08% according to company testing.

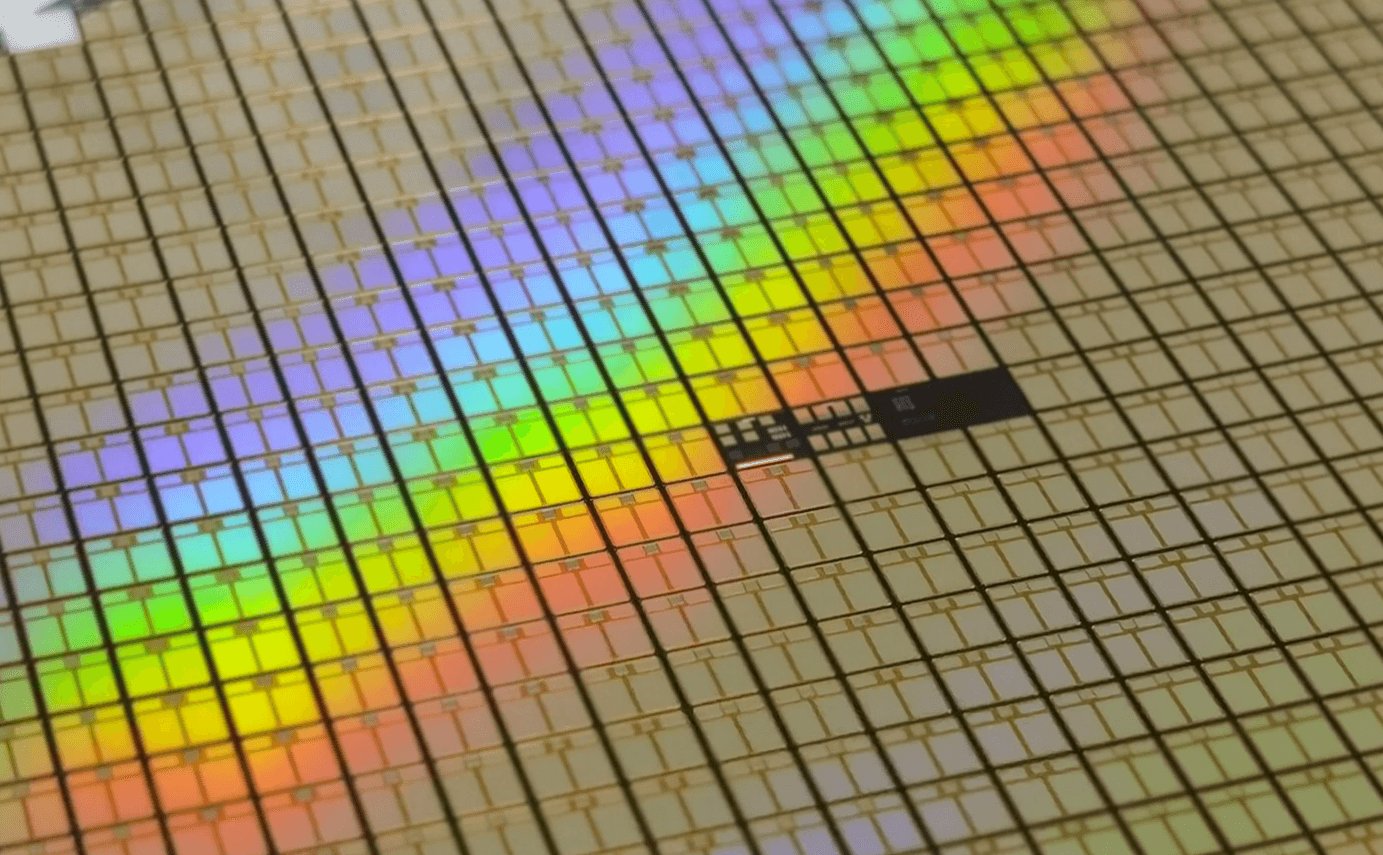

The system represents Li Auto's first complete in-house powertrain design, spanning six integrated components: SiC power chips, power modules, motor controllers, electric motors, reduction gearboxes, and control software. This vertical integration contrasts with industry norms where automakers typically source components from suppliers like Bosch or Valeo.

Technical documentation indicates several novel approaches. The hexagonal cell structure of Li Auto's custom SiC chips reduces internal resistance by approximately 15% compared to conventional designs, enabling better thermal distribution under high-voltage (800V) operation. This contributes to the system's claimed energy consumption of 14.8 kWh per 100 km under China Light-Duty Vehicle Test Cycle (CLTC) conditions, translating to a 720 km maximum range.

Cold-weather performance receives specific attention through a proprietary motor lubricant formulation. Li Auto claims this reduces powertrain energy loss at -7°C temperatures, extending range by 10-16 km compared to standard lubricants. The thermal management system works in conjunction with a 97.8 kWh battery supporting 5C charging rates, enabling 500 km of range recovery within 10 minutes using compatible ultra-fast chargers.

While the efficiency figures set new benchmarks for production vehicles, real-world performance validation remains pending. The 93.08% efficiency claim applies to peak operating conditions; actual highway driving efficiency typically drops by 8-12% due to aerodynamic loads and accessory usage. Production scalability of the custom SiC chips also presents challenges, as global semiconductor capacity for automotive-grade SiC remains constrained.

The recognition reflects China's accelerating EV component development amid supply chain localization efforts. Unlike previous Li Auto models relying on range extenders, the i8 platform represents the company's transition to full battery-electric architectures. Industry analysts will monitor how the proprietary powertrain affects manufacturing costs and serviceability as the i8 enters volume production later this year.

Comments

Please log in or register to join the discussion