AtmosZero's novel heat pump technology replaces combustion boilers with an electrified solution capable of generating 150°C steam at 50% lower operating costs than conventional electric boilers.

For over two centuries, steam boilers powered by fossil fuels have been indispensable to global industry, enabling everything from food processing to pharmaceutical manufacturing. This legacy comes at an environmental cost: steam production accounts for 5% of global energy-related emissions, releasing over 2.2 gigatons of CO₂ annually. AtmosZero, founded by MIT alumni, has engineered a modular heat pump system designed to electrify this foundational industrial process while overcoming key limitations of existing alternatives.

Technical Approach

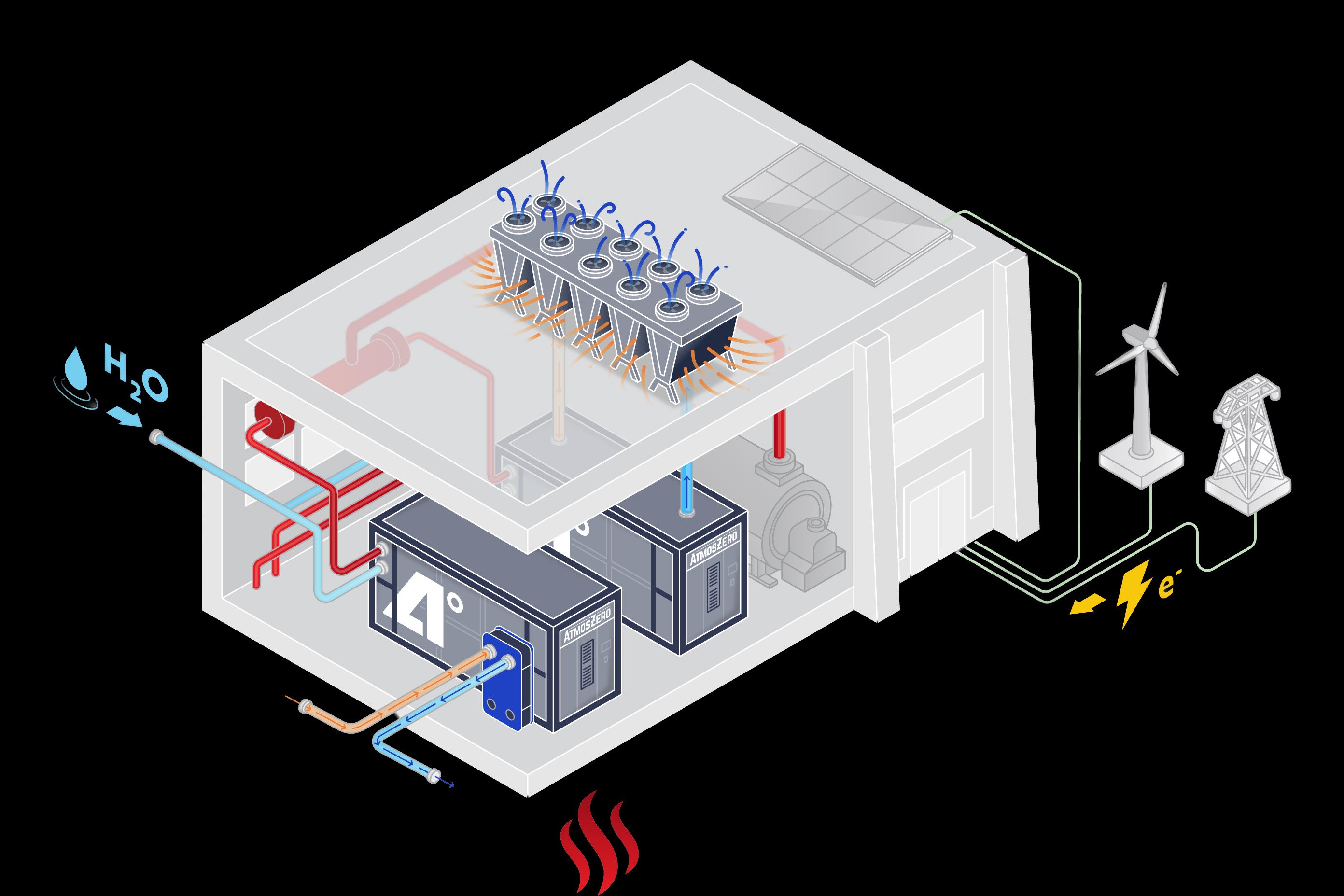

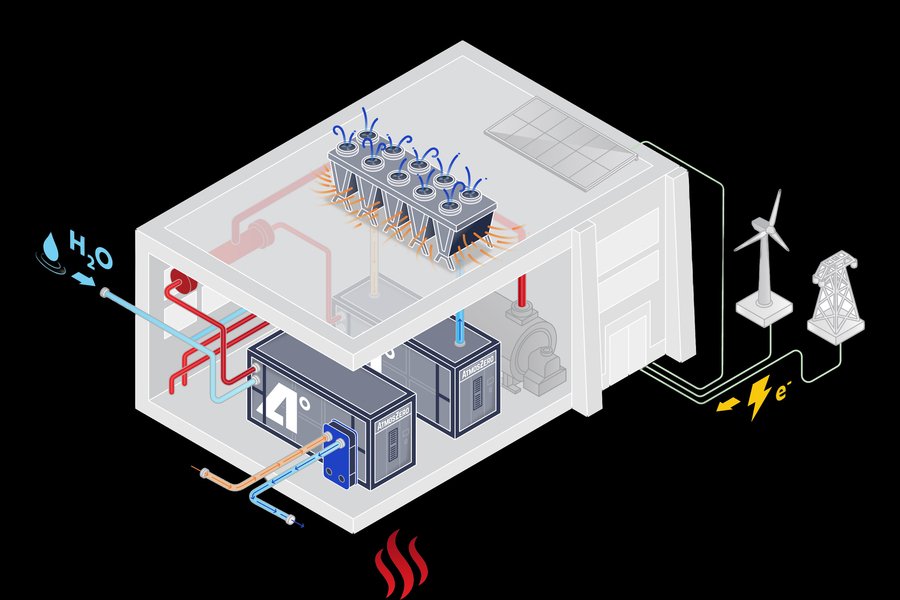

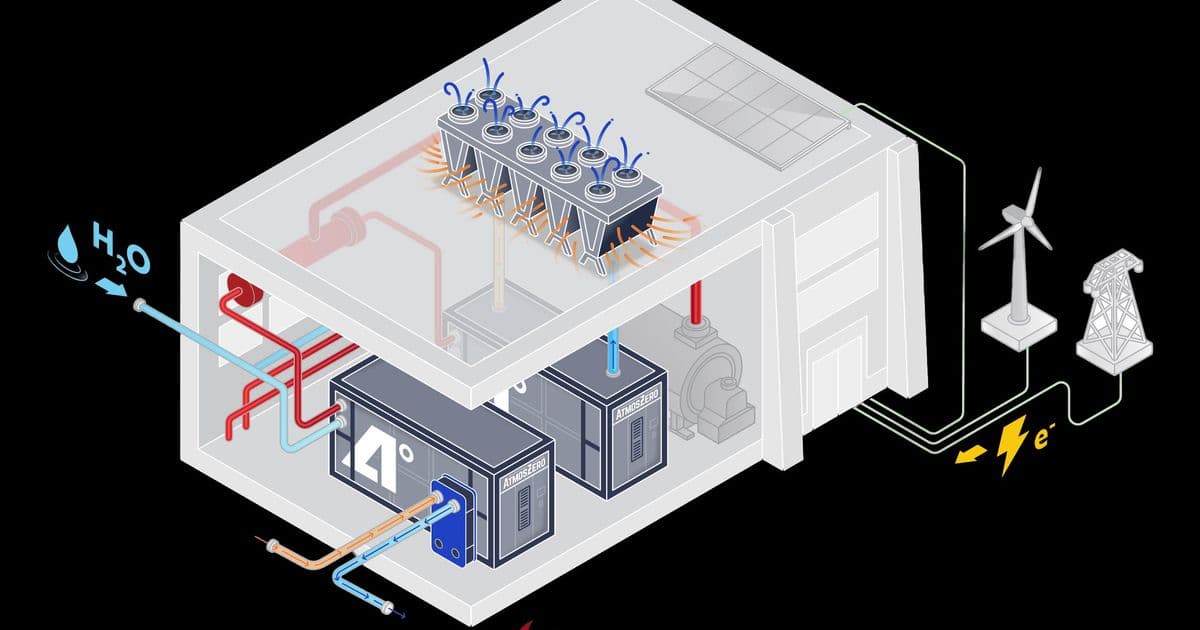

AtmosZero's core innovation lies in its refrigerant compression system, which achieves temperatures up to 150°C—sufficient for most industrial steam applications. Unlike conventional electric boilers that use resistive heating (typically operating at 50-60% efficiency), AtmosZero's staged compressor technology recovers heat at multiple points in the cycle. Ambient-temperature air warms a liquid heat transfer material, which evaporates refrigerant before it enters a series of precisely manufactured compressors and heat exchangers.

"The compressor is the engine defining efficiency, cost, and performance," explains CEO Addison Stark (MIT SM '10, PhD '14). "By optimizing for specific operational windows and refrigerants, we maximize compression stages to achieve ultra-efficiency—using 50% less electricity than resistive boilers."

Crucially, the system operates without requiring waste heat sources, a limitation that complicates installations for competing technologies. This allows AtmosZero's units to function as true drop-in replacements for combustion boilers, maintaining identical steam delivery protocols without process modifications.

Deployment and Scalability

The company's pilot 650 kW system is already operational in Colorado, with a 1 MW unit slated for deployment. Each modular unit fits within shipping containers, enabling rapid installation. "Our system can be installed in an afternoon and deployed in days with zero downtime," Stark notes. This plug-and-play approach eliminates retrofitting costs that hinder other decarbonization efforts.

AtmosZero initially targets facilities with under 10 MW thermal demand—representing most U.S. manufacturing sites. Production will scale from dozens of units annually toward hundreds within three years. The modular design allows capacity expansion through parallel deployment, avoiding the engineering complexities of custom-built solutions.

Context and Limitations

While promising, the technology faces thermodynamic constraints. Heat pump efficiency decreases as output temperatures rise, making ultra-high-temperature applications (200°C+) currently impractical. Stark acknowledges this limitation but emphasizes that 150°C covers most industrial needs: "Steam remains indispensable—we're enabling its decarbonization rather than reinventing workflows."

Financially, AtmosZero must prove long-term reliability to overcome industry conservatism. Their pilot aims to demonstrate year-round durability in varied climates—a critical step toward widespread adoption.

Industrial Impact

This innovation arrives amid growing pressure to decarbonize industrial heat, which constitutes 20% of global energy consumption. Unlike sector-specific solutions like Boston Metal (steel) or Sublime Systems (cement), AtmosZero targets steam's cross-industry ubiquity. As Stark articulated in his 2020 Joule article, "To decarbonize industry, we must decarbonize heat", steam electrification represents a systemic opportunity.

With manufacturing giants increasingly committing to net-zero targets, AtmosZero's technology could significantly reduce emissions in sectors resistant to electrification. As Stark observes: "What we offer is the ability to decarbonize steam without changing two centuries of industrial design."

Related MIT programs: Technology and Policy Program | Department of Mechanical Engineering

Comments

Please log in or register to join the discussion