Engineers can now simulate the complex magnetization process of permanent magnets using manufacturer datasheets alone, validating results against Ansys Maxwell's built-in libraries. This workflow enables accurate prediction of magnetic behavior for critical applications like EV motors and sensors, bridging gaps in material data availability.

Permanent magnets form the backbone of technologies from electric vehicle motors to medical devices, yet accurately simulating their magnetization process has long required comprehensive material data. A new workflow in Ansys Maxwell demonstrates how engineers can derive precise magnetic behavior models solely from manufacturer datasheets—overcoming a key hurdle in electromagnetic design.

The Physics Behind Magnetization

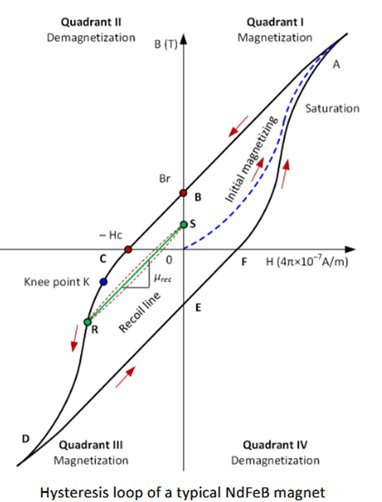

At its core, magnetization involves navigating the B-H hysteresis curve. When unmagnetized material (like NdFeB alloy N48SH) encounters a strong external field, it follows an initial curve to saturation. Upon field removal, it recoils to an operating point on the demagnetization curve—dictating its real-world performance. As the article explains:

"A permanent magnet in open air generates a demagnetizing field opposing its magnetization. The intersection of this field and the material's B-H curve determines its operating point."

Building the Simulation Workflow

The process begins by digitizing the datasheet's graphical demagnetization curve using Maxwell's SheetScan tool. Engineers then extrapolate this into an initial magnetization curve, aligning it with a generic NdFeB profile for continuity. Crucially, the "Compute magnetized operating points" flag must be enabled for the permanent magnet object.

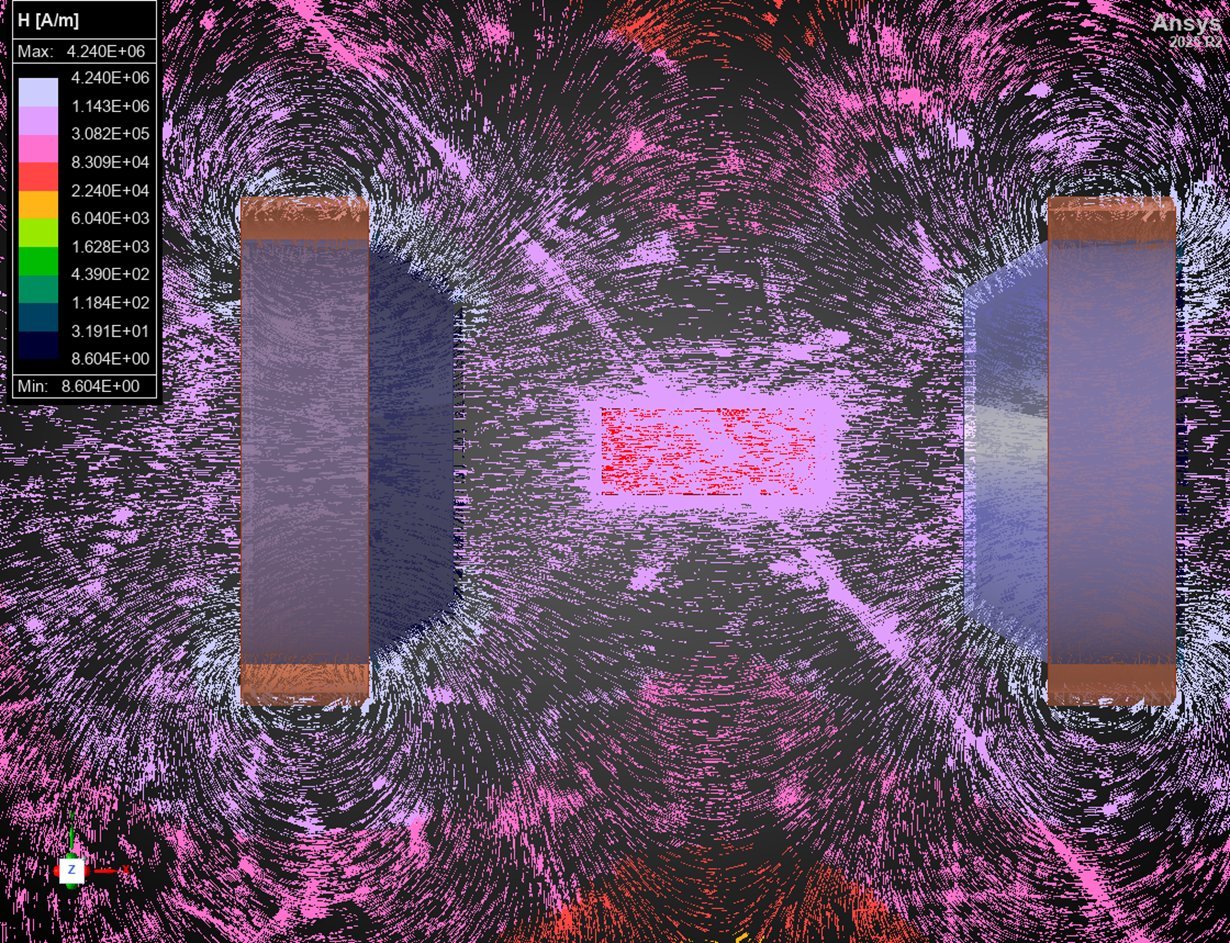

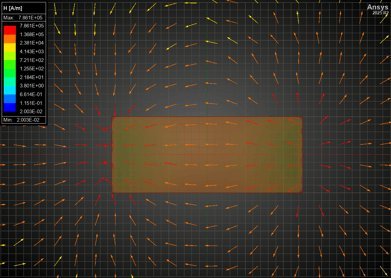

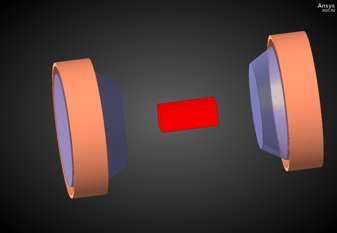

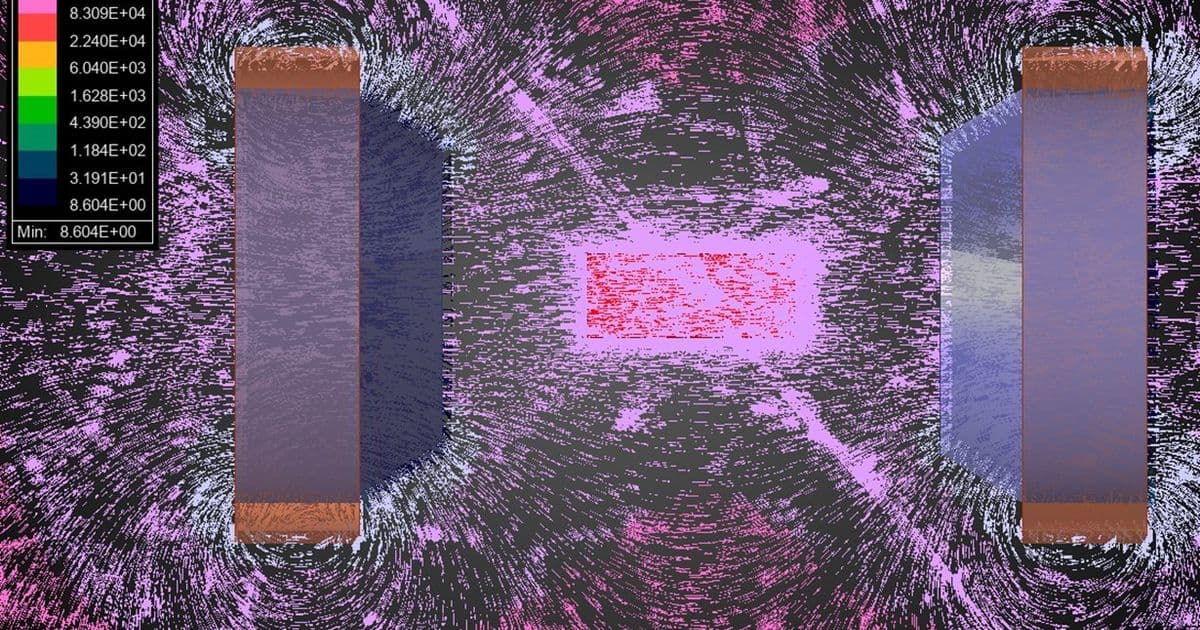

Two linked magnetostatic analyses drive the simulation:

- Magnetizing Event: Coils apply current to drive the material to saturation.

- Magnetized State: Current disabled, with magnetization state mapped to a permanent magnet field source.

The resulting recoil path reveals the final operating point. Validation against Maxwell’s built-in N48SH material showed near-identical results—confirming the method's accuracy.

Why This Matters for Engineers

This approach democratizes high-fidelity electromagnetic simulation:

- Design Flexibility: Model proprietary or niche magnets lacking full datasets.

- Validation Confidence: Cross-check results against established materials.

- Efficiency: Avoid physical prototyping for magnetization process optimization.

The technique exemplifies how simulation tools bridge theoretical physics and practical engineering, ensuring devices from actuators to energy systems perform reliably under real-world demagnetizing forces. As computational methods mature, they unlock deeper material insights—transforming datasheets into dynamic design assets.

Source: Ozen Engineering Blog by Ian Chavez

Comments

Please log in or register to join the discussion