Prusa Research CEO steps in as interim leader after David Randolph's departure, overseeing North American expansion plans and the search for a permanent successor.

Josef Prusa, CEO of Prusa Research, has taken emergency command of Printed Solid as interim leader following the departure of David Randolph after nearly a decade at the helm. The move, announced on social media and effective January 1st, places the European 3D printing giant's founder directly in charge of its North American operations during a critical transition period.

Randolph's exit marks the end of an era for the Delaware-based company, which he transformed from a small 3D printing supplier into a key manufacturing hub for Prusa's European-designed hardware. Under his leadership, Printed Solid established itself as more than just a distributor, becoming an integral part of Prusa's global supply chain.

Prusa's American Manufacturing Ambitions

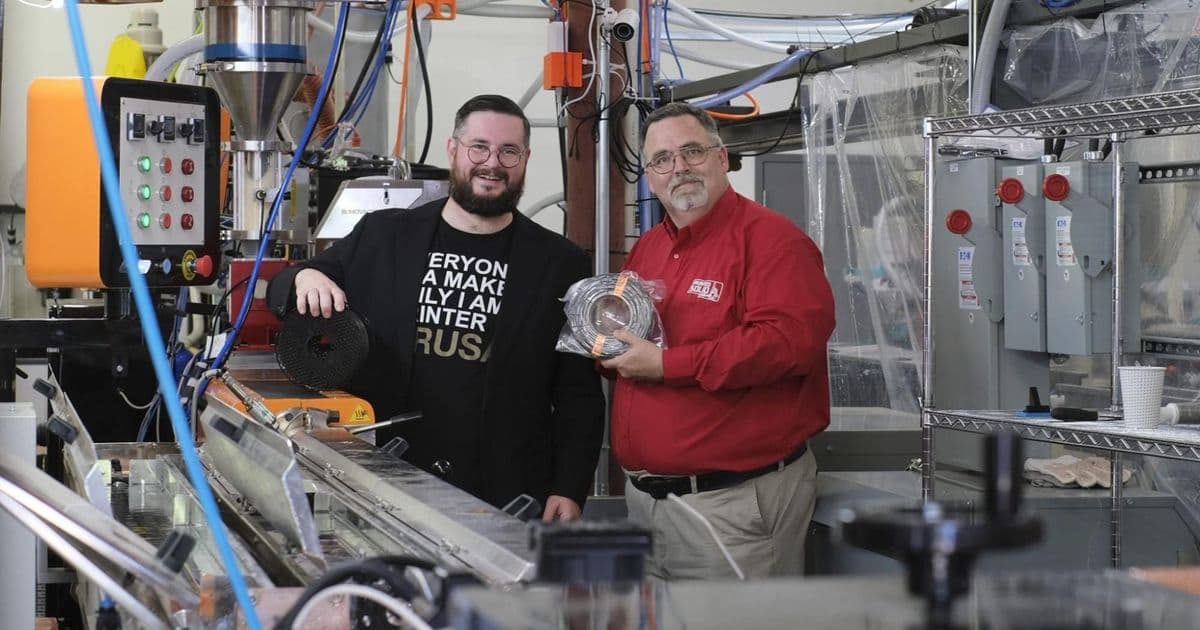

The timing of Randolph's departure coincides with Printed Solid's push toward domestic manufacturing. The company operates a small Prusa print farm in Delaware that produces parts for MK4S and Core One 3D printers assembled locally. Work is currently underway to source sufficient American-made components to earn the coveted "MADE in the USA" designation for these printers.

Josef Prusa has publicly stated his ambition to make his team the largest 3D printer and filament manufacturer in the United States. This goal aligns with broader industry trends toward reshoring manufacturing capabilities and reducing dependency on overseas supply chains, particularly in light of recent global disruptions.

Transition and Continuity

Chief Sales Officer Chris Pelesky has emphasized that operations remain "business as usual" during the transition. The management team is working closely with Prusa HQ to maintain alignment between the companies' core missions and ensure continuity for customers and partners.

"Jo has been working with the remainder of the Printed Solid management team, myself included, along with our longtime liaison, Sam, who helps with any Prusa HQ needs that we have," Pelesky explained. "We are the same company we were in 2025, with the same goals of advancing sales and manufacturing of Prusa 3D printers here in the U.S."

Randolph's Legacy

During his tenure, Randolph helped establish Printed Solid as a cultural touchstone in the 3D printing community. His background as a broadcast engineer for the Discovery Channel and G4TV influenced the company's approach to content and community engagement. He's perhaps best known for creating niche products that resonated with retro computing enthusiasts, including Beige 500 and Tan 64 PLA filaments that perfectly match the cases of an AMIGA 500 and a Commodore 64.

Randolph also played a crucial role in preserving Polyalchemy Elixir, a fan-favorite silk filament. When the original manufacturer shut down, he purchased the formula and spent two years reengineering it to work on Printed Solid's equipment. The result was Jessie Elixir, named after his dog who served as the company mascot. All of Printed Solid's filament colors are named for Jessie, whose likeness is used to showcase products on the website.

The Search for a Successor

While a permanent successor has not yet been named, the search process is underway. The transition raises questions about the future direction of Printed Solid under new leadership, particularly as the company balances its role as a distributor with its growing manufacturing capabilities.

The appointment of Josef Prusa as interim CEO suggests that Prusa Research views Printed Solid as strategically important to its North American ambitions. With the company working toward domestic manufacturing certification and expansion plans, having the parent company's CEO directly involved signals the significance of this transition period.

Industry Context

Printed Solid's evolution reflects broader trends in the 3D printing industry, where companies are increasingly seeking to control more of their supply chains and establish local manufacturing capabilities. The push for "MADE in the USA" certification represents both a marketing advantage and a strategic move to insulate against international trade tensions and supply chain disruptions.

As the 3D printing industry continues to mature, the success of Printed Solid under new leadership could serve as a model for how European companies can effectively establish and grow their presence in the American market while maintaining quality standards and brand identity.

The coming months will be critical as Josef Prusa oversees the transition and works to identify a permanent successor who can continue the momentum Randolph built while advancing Prusa's ambitious goals for North American manufacturing and market share.

Comments

Please log in or register to join the discussion