From running DOOM on a charging station to crafting atomic-scale PCB repairs, August 2025 showcased the relentless ingenuity of the maker community. This roundup highlights groundbreaking projects blending precision engineering, creative coding, and open-hardware artistry that redefine what's possible in DIY tech. Discover how persistence and flux transformed missteps into masterpieces.

The August 2025 maker landscape proved that curiosity fused with technical grit yields extraordinary results. This month's projects demonstrated not just skill, but a philosophy: constraints breed innovation, and failure is merely a prototyping step. Here’s how hackers, tinkerers, and engineers pushed boundaries:

Precision at the Microscopic Scale

- Microsurgery for Miswired LEDs: atomic14 transformed a botched RGB LED footprint into a functional triumph using microscope-assisted rework. By employing enamel wire jumpers and UV solder resist under high magnification, they salvaged a board destined for the scrap heap—showcasing repair techniques rivaling semiconductor fabs.

- VCC-GND Swap Recovery: In another feat, atomic14 documented reversing polarity damage on a micro-LED. Strategic flux application and hot-plate resuscitation turned a catastrophic error into a masterclass in PCB triage.

Shattering Performance Limits

- USB’s Hidden Bandwidth: Forget baud rates. atomic14 wired an ESP32-S3 directly to native USB, bypassing legacy serial constraints to achieve 7 Mbps throughput—60x faster than traditional 115 kbit/s UART. This hack liberates embedded devices from artificial bottlenecks.

- Teensy-Powered Cylon Vocoder: element14 presents transformed a Teensy 4.0 and audio shield into a real-time 16-band vocoder. Custom DSP algorithms reconstructed speech with Battlestar Galactica menace, paired with 3,500-LED visual feedback—all in a solderable package.

Hardware as Art & Function

- Open Hardware Summit Highlights: Edinburgh’s event featured PCB snowflakes, conductive mushroom MIDI controllers, and laser-etched wearable tech. bleeptrack demonstrated that open-source tools enable creations straddling lab equipment and gallery pieces.

- Printegrated Circuits: Oliver Child pioneered pausing 3D prints to inject conductive filament, embedding microcontrollers inside objects like sensor-laden mushrooms. This technique erases the line between printing and circuit assembly.

Pushing DOOM to the Edge

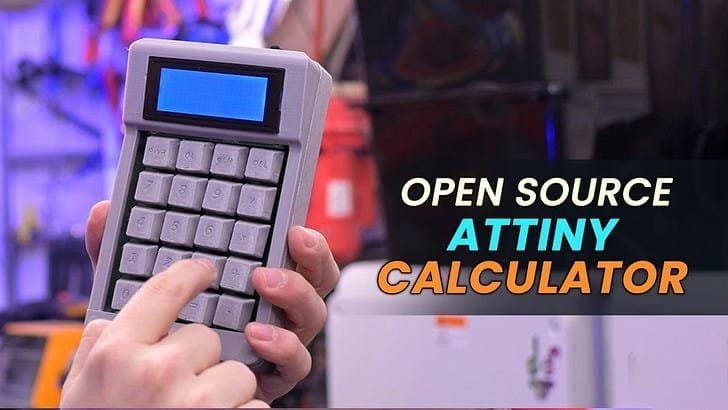

- Anker Charger Gaming Rig: Aaron Christophel ported DOOM to an Anker Prime Charging Station by reverse-engineering its Sunvit display and leveraging an ESP32-C3. Following his earlier feat on a Xiaomi Mi Band (2MB flash/1MB RAM), this proves no device is safe from id Software’s legacy.

- Pocket Adding Machine Revival: element14 presents resurrected clacky calculators using Cherry MX switches and an ATtiny3226, compressing retro functionality into a repairable AAA-powered slab.

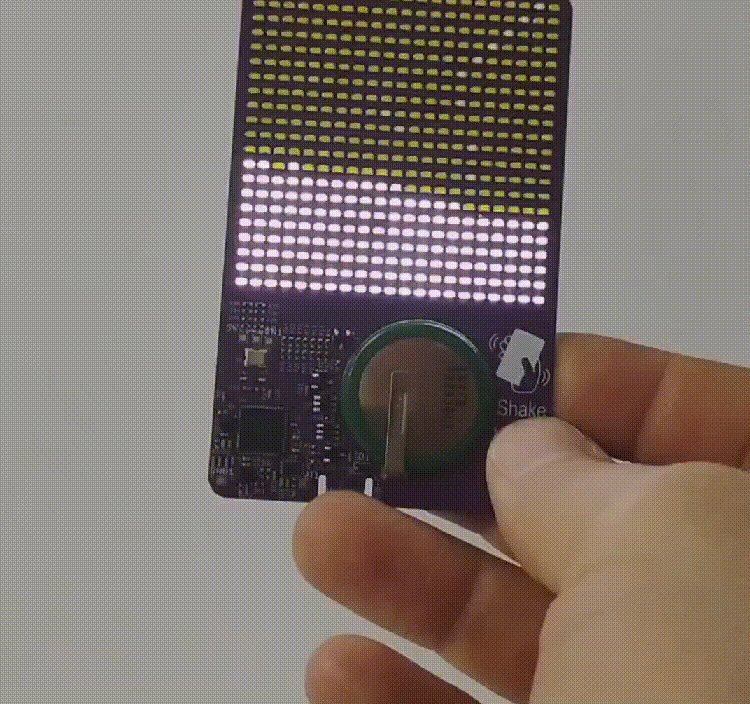

Physics in Your Pocket

- Fluid Sim Business Card: A wallet-sized PCB runs real-time FLIP fluid simulations via Rust firmware and WebAssembly debugging—networking meets computational fluid dynamics.

- Candle-Powered Clock: A RISC-V chip measured ionized air fluctuations from bundled candles, creating a surprisingly accurate 9.9Hz oscillator divided to 1Hz pulses.

Infrastructure Hacking

- Grid Frequency Detection: An audio lead coiled around a power cord captured the Baltic grid’s switch from Russian to EU synchronization. Python and FFT analysis turned electromagnetic interference into a geopolitical sensor.

- Lawnmower Server: Jotun equipped a mower with a Pi, UPS, and GRE tunneling for remote management—proving uptime thrives even in grassy, dusty conditions (#lawnmower channel essential).

The Bigger Picture

These projects underscore critical shifts: USB-C and ESP32-S3 are democratizing high-speed interfaces, sensor fusion enables accessible spatial computing (as seen in atomic14’s gyro-driven 3D PCB viewer), and "printegration" could revolutionize IoT device fabrication. The harmonic-drive telescope mount—built for €300 instead of €4,000—exemplifies how maker ingenuity disrupts prohibitively expensive niches.

Maker culture isn’t just about building; it’s about reimagining the relationship between tools and creativity. When a candle’s flicker becomes a timebase or a lawnmower hosts a server, we’re reminded that the most compelling tech narratives emerge from soldering irons, not boardrooms. Source: Maker News - August 2025 Update

Comments

Please log in or register to join the discussion