China's top chipmaker SMIC warns that soaring memory prices are forcing consumers to cut back on entry-level electronics, causing a ripple effect through the semiconductor supply chain as fabless developers revise foundry orders.

The semiconductor industry is facing a perfect storm of memory hoarding and skyrocketing prices that is squeezing out consumers and reshaping foundry orders across the supply chain. China's top chipmaker SMIC has issued a stark warning about the cascading effects of elevated commodity memory costs on entry-level electronics manufacturing.

According to SMIC co-CEO Zhao Haijun, the combined impact of increased memory prices has resulted in a significant decline in mid to low-end smartphone processor orders received by foundries. During an earnings call with financial analysts and investors, Zhao explained that end-user companies in these segments are facing unprecedented pressure from both tight supply and rising prices for memory chips.

"Even if end-user companies can pass on these cost increases to consumers via end-product price rises, such moves will lead to a decline in demand for end products," Zhao stated. This creates a vicious cycle where higher component costs force manufacturers to either absorb losses or pass them to consumers, ultimately dampening demand.

One of the key factors contributing to the sharp rise in 3D NAND and DRAM prices is memory overbooking. Many PC and smartphone makers tried to order more memory than they actually needed, causing prices to skyrocket and forcing companies to adjust their business outlook. This behavior, while intended to secure supply, has paradoxically created the very shortages and price volatility it sought to avoid.

SMIC's executives first discussed this situation back in November, noting that makers of inexpensive consumer electronics and smartphones are struggling to obtain memory while facing excessive prices. As a result, they are adjusting their inventory of entry-level and mid-tier application processors to avoid sitting on stocks full of system-on-chips (SoCs) while being unable to produce handsets.

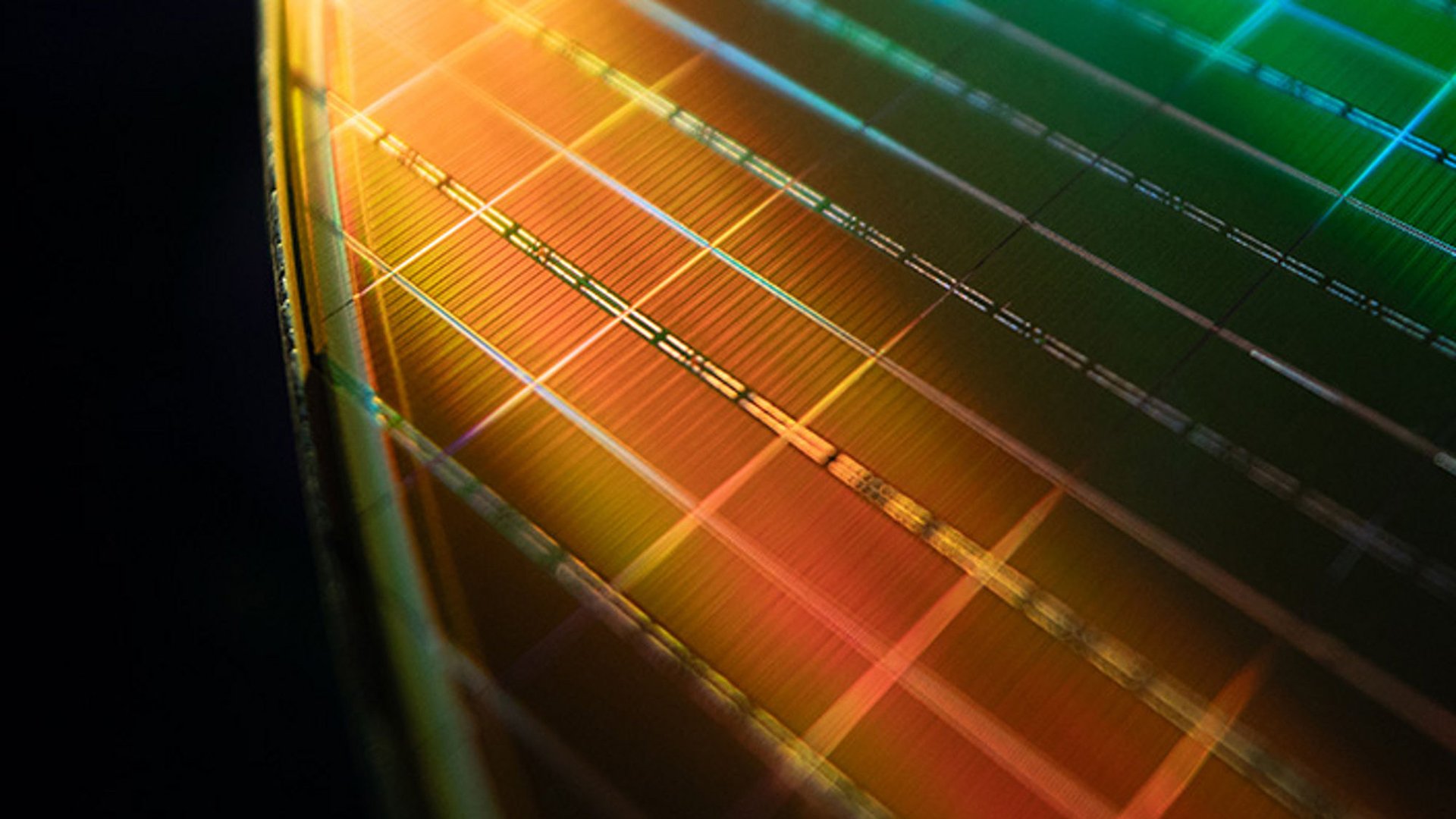

This inventory adjustment has a direct impact on foundry orders. As SMIC's clients among developers of mobile SoCs alter their orders accordingly, the foundry itself must revise its production schedules and capacity planning. The ripple effect extends throughout the semiconductor ecosystem, affecting everything from wafer starts to equipment utilization.

TSMC, the world's largest contract chip manufacturer, has confirmed similar expectations of minimal smartphone processor unit growth, primarily due to volume declines of entry-level and mainstream SoCs. However, TSMC is somewhat insulated from these demand drops because the majority of its application processors are aimed at high-end, mainstream smartphones that are less sensitive to fluctuations in DRAM and 3D NAND prices.

"As for PC or the smartphone, to tell the truth, we expect a higher memory price, so we expect the unit growth will be very minimal," said C.C. Wei, chief executive of TSMC, during a recent earnings call. "But for TSMC, we did not feel our customers changed their behavior. We supply most of the high-end smartphones. The high-end smartphone is less sensitive to the memory price. So, the demand is still strong."

The divergence between high-end and entry-level markets highlights a fundamental shift in the semiconductor industry. While premium devices continue to see strong demand, the entry-level segment is being squeezed by multiple factors including memory costs, supply constraints, and changing consumer preferences.

Despite declining sales of SoCs for inexpensive handsets, SMIC does not expect its revenues to decline sharply. The company believes it has some 'protection' against such drops due to China's push for domestic semiconductor development and manufacturing. As China adopts more and more chips that are developed and made domestically, SMIC expects to maintain its growth trajectory.

"In 2026, the effects of industrial chain reshoring from overseas and domestic customers, new products, replacing legacy overseas products will persist, creating sustained incremental growth opportunities for the domestic industrial chain," Zhao said. This strategic positioning could help SMIC weather the current market turbulence while positioning itself for long-term growth in the Chinese market.

The memory price crisis is part of a broader trend affecting the entire semiconductor supply chain. AI data centers are swallowing the world's memory and storage supply, creating unprecedented demand for high-bandwidth memory (HBM) and other advanced memory technologies. This demand is driving up prices across all memory segments, from commodity DRAM to cutting-edge HBM used in AI accelerators.

Industry analysts are closely watching how this situation will evolve. The memory market has historically been cyclical, with periods of shortage followed by oversupply. However, the current situation is complicated by structural changes in the industry, including the rise of AI computing, geopolitical tensions affecting supply chains, and changing consumer behavior in the post-pandemic era.

For consumers, the impact is already being felt in the form of higher prices for entry-level electronics. Budget smartphones, basic laptops, and other affordable devices are becoming more expensive or seeing reduced availability as manufacturers struggle with component costs and supply constraints. This could have long-term implications for digital inclusion and access to technology in emerging markets.

For the semiconductor industry, the current situation serves as a reminder of the complex interdependencies in the global supply chain. Memory pricing doesn't just affect memory manufacturers – it cascades through the entire ecosystem, from fabless design houses to foundries to end-product manufacturers and ultimately to consumers.

As the industry navigates these challenges, companies are likely to continue adjusting their strategies. This may include diversifying supply chains, investing in vertical integration, developing alternative memory technologies, and finding ways to reduce dependence on volatile commodity components. The coming months will be crucial in determining whether the current memory crisis is a temporary blip or a sign of more fundamental changes in the semiconductor landscape.

The situation also highlights the importance of strategic planning and risk management in the semiconductor industry. Companies that can anticipate and adapt to supply chain disruptions, price volatility, and changing market conditions will be better positioned to weather the current storm and emerge stronger in the long run. As memory prices continue to fluctuate and consumer demand patterns evolve, the entire semiconductor ecosystem will need to remain agile and responsive to survive and thrive in this challenging environment.

Comments

Please log in or register to join the discussion