MIT's 2.009 mechanical engineering capstone culminated in six product prototypes addressing real-world challenges through rigorous design iteration, demonstrating how engineering solutions evolve through continuous refinement.

At MIT's annual 2.009 Product Engineering Process showcase, 97 mechanical engineering students demonstrated how embracing iterative design cycles transforms conceptual ideas into functional prototypes. This year's theme—"Cycles"—highlighted the non-linear engineering process where "teams loop between ideas, prototypes, failures, fixes, and breakthroughs," according to lecturer Josh Wiesman. The six teams presented solutions spanning medical emergencies, agricultural efficiency, and recreational safety, each developed through 13 weeks of user-centered design and technical refinement.

Green Team: Automated CPR Delivery

The Green Team addressed the critical decline in CPR effectiveness during prolonged resuscitation attempts. Their HeartBridge device delivers consistent chest compressions at the American Heart Association's recommended depth (5-6 cm) and rate (100-120 compressions/minute). The electromechanical system incorporates force sensors to maintain optimal pressure and provides visual/auditory feedback through an integrated display. Unlike manual CPR where effectiveness drops after three minutes, HeartBridge maintains precision indefinitely. The team validated compression accuracy using force plates and conducted usability studies with EMT trainees.

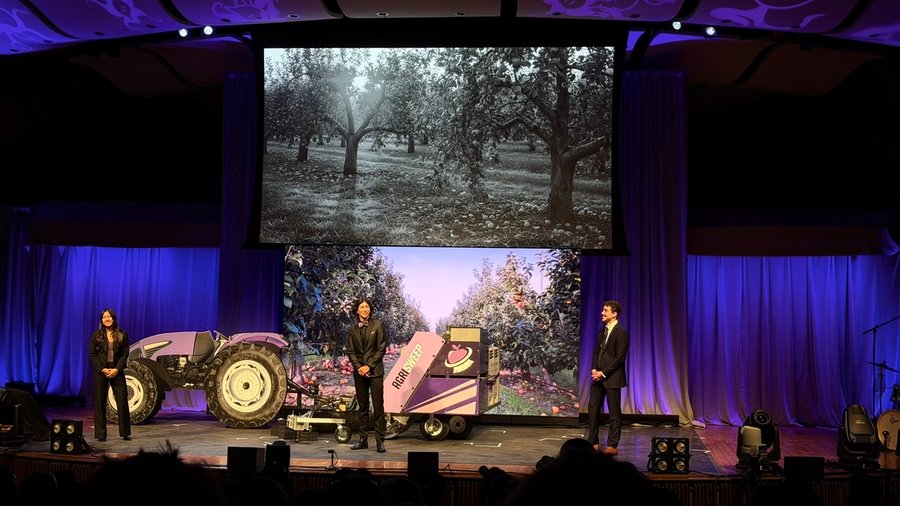

Purple Team: Agricultural Waste Reduction

AgriSweep tackles the $150M annual loss from fallen apples in U.S. orchards. This hydraulic-powered tractor attachment uses counter-rotating brushes to gather apples into a conveyor system that deposits them into standard produce bins. The modular design accommodates various orchard terrains and integrates with common tractor PTO systems. By automating collection, AgriSweep reduces labor costs by up to 70% compared to manual pickup while preventing fungal spread from decaying fruit. Prototype testing achieved 85% collection efficiency on uneven terrain.

Red Team: Accessible Embroidery Design

Scribbly revolutionizes hand embroidery by eliminating complex pattern transfers. The self-contained device reads vector files from USB drives and precisely plots designs onto fabric stretched in hoops up to 10" diameter. A thermal erasing mechanism allows redesigns without fabric waste. The pen assembly uses servo-controlled XY gantry movement with ±0.5mm accuracy, validated through repeatability tests on multiple fabric types including linen and stretch knits.

Blue Team: Marine Safety Innovation

DORI addresses propeller strike injuries (causing 200 annual U.S. fatalities) with a deployable guard that activates only during high-risk scenarios. The stainless-steel mechanism remains stowed above water during normal operation, eliminating drag from fixed guards that reduce fuel efficiency by 15-20%. When deployed via cockpit switch, telescoping arms lower a polycarbonate shield around the propeller within three seconds. Hydrodynamic simulations confirmed <5% thrust loss when engaged.

Yellow Team: Precision Ice Resurfacing

Polar brings professional ice maintenance to backyard rinks. The battery-powered unit features a heated stainless steel blade that shaves ice to 0.5mm flatness tolerance, followed by a heated water distribution system that lays precise micron-thick resurfacing layers. Thermoelectric modules regulate blade temperature while regenerative braking recovers 30% of motion energy. Field tests showed consistent NHL-quality ice hardness (≥85 Shore D) after processing.

Pink Team: Aquatic Rescue Optimization

HydroHold gives rescue divers hands-free victim securement during critical drowning rescues. The carabiner-based system integrates directly into buoyancy compensator vests, deploying a retractable strap with one-handed operation. The titanium locking mechanism withstands 500kg loads while remaining corrosion-resistant in saltwater. Developed with Massachusetts rescue divers, prototypes underwent 200+ deployment tests in turbulent water conditions. The design prioritizes simplicity—requiring less than two seconds to engage—proving that refined solutions often outperform complex ones.

Each solution exemplified the course's emphasis on cyclical refinement: Teams conducted over 300 user interviews collectively, built 15-20 iterative prototypes per project, and performed rigorous failure mode analysis. As professor Peko Hosoi noted, "Powerful engineering isn't about flashy things... it's about reducing friction and building something that works when it matters." The prototypes now enter further development cycles, with several teams pursuing patent applications and industry partnerships.

Full product demonstrations: 2.009 Cycles Livestream Course methodology: Product Engineering Process

Comments

Please log in or register to join the discussion