Chinese enthusiast XNX crafts unified gaming system using lost-wax casting and shared 250W power supply, overcoming significant engineering challenges to combine three consoles.

Chinese hardware modder 小宁子 XNZ has achieved what many gamers dream about: a single chassis housing PlayStation 5, Xbox Series X, and Nintendo Switch 2 hardware. Dubbed the 'Ningtendo PXBOX 5,' this engineering marvel solves the space and power cable clutter problems of multi-console setups through innovative thermal management and power distribution systems.

Triangular Foundation

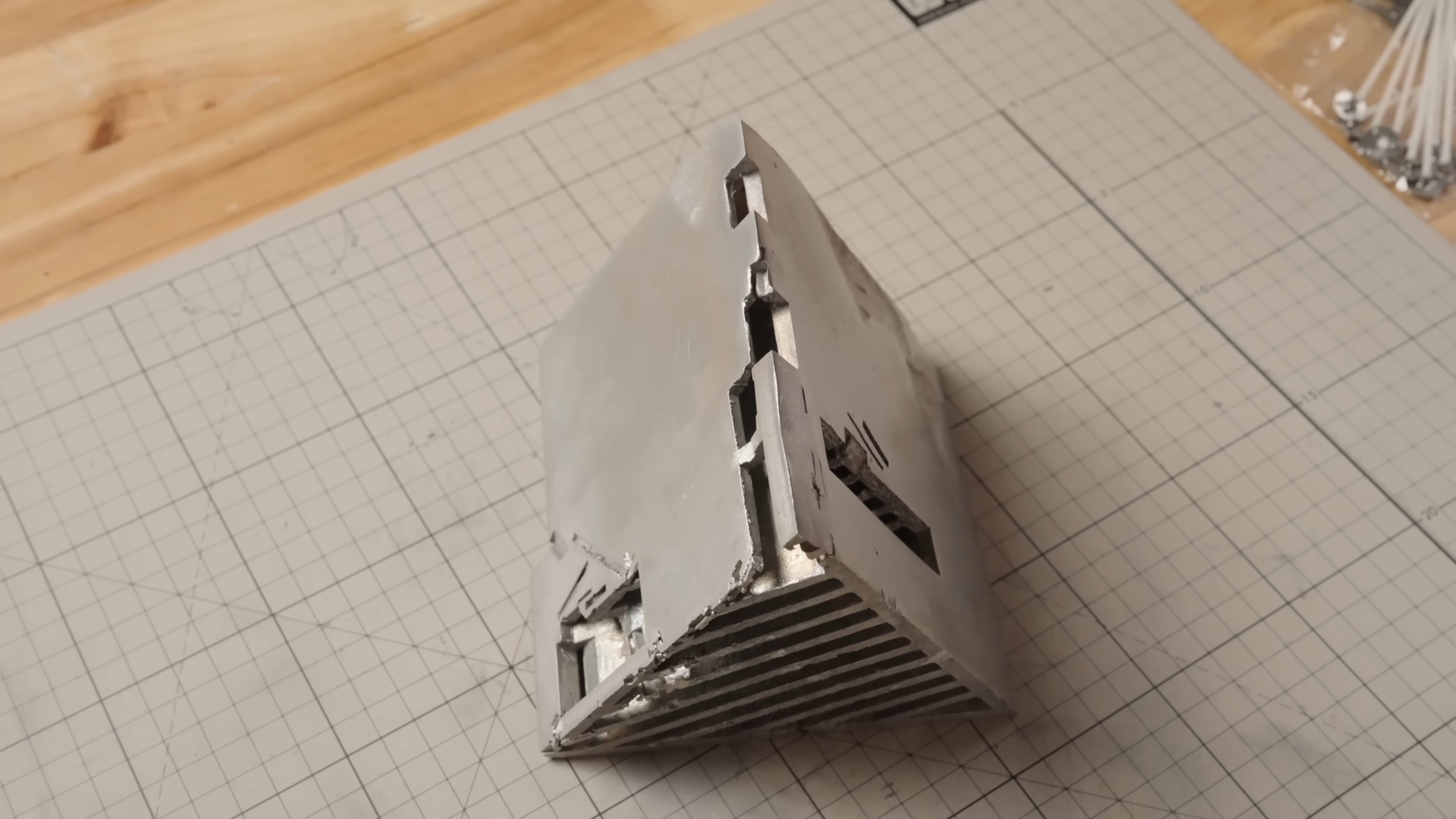

XNZ drew inspiration from Apple's cylindrical Mac Pro design, leveraging its triangular symmetry to mount each console's motherboard on separate internal faces. After stripping all three consoles down to their core components, XNZ discarded original cooling solutions and power supplies to develop unified systems. The triangular arrangement positions each motherboard facing outward with a central cooling column.

Thermal Innovation Through Ancient Techniques

The most significant challenge emerged in cooling three high-performance systems simultaneously. Initial attempts with 3D-printed heatsinks proved prohibitively expensive for CNC machining. This led XNZ to revive lost-wax casting, a 3,000-year-old metalworking technique:

- Created PLA plastic mold of triangular heatsink

- Coated mold with heat-resistant ceramic slurry

- Burned away PLA core in kiln

- Poured molten aluminum into cavity

The resulting aluminum block (after polishing and support removal) became the thermal backbone. Copper contact plates interface between the block and PS5/Xbox SoCs, maintaining temperatures around 60°C under load after replacing liquid metal with standard thermal paste.

Power Integration and Switch Implementation

Power measurements revealed key insights:

| Console | Idle Power | Peak Power |

|---|---|---|

| PS5 | <5W | 225W |

| Xbox Series X | <5W | 225W |

| Switch 2 | Minimal | Minimal |

A single 250W GaN power supply suffices since only one console operates at full capacity simultaneously. The Switch 2 integration required particular ingenuity – its motherboard mounts directly to the cooler while a custom dock connector enables hot-swapping between handheld and docked modes.

Mechanical Execution

The final assembly features:

- Phanteks T30 120mm bottom intake fan

- Triangular aluminum chassis housing

- Color-coded LED lighting system

- Arduino-based switching controller

- Physical selection button

Transition between consoles takes approximately three seconds. The system automatically cuts power to inactive consoles when switching, though users must quit games before transition to prevent overloading the shared PSU.

Technical Trade-offs

While achieving remarkable integration, the design carries limitations:

- Digital-only operation (disc drives excluded)

- Requires game closure before console switching

- Maximum 250W power budget prevents simultaneous multi-console operation

Despite these constraints, XNX's creation demonstrates remarkable engineering resourcefulness. The lost-wax casting approach particularly stands out – enabling custom, cost-effective thermal solutions unavailable through conventional manufacturing. This project pushes boundaries of what determined modders can achieve outside factory production lines.

Comments

Please log in or register to join the discussion