Brian Potter's exploration of 'AWS for Everything' envisions a future where large-scale automated facilities leverage economies of scale to produce diverse outputs efficiently, potentially revolutionizing manufacturing, research, and beyond.

In the evolving landscape of industrial production, Brian Potter's concept of 'AWS for Everything' presents a compelling vision for how automation and scalability might converge to transform how we create goods and conduct research. This idea draws a parallel between Amazon Web Services' cloud computing model and potential physical production systems, suggesting that as automation technology becomes increasingly flexible, we may see the emergence of large-scale facilities capable of producing an astonishing variety of outputs efficiently.

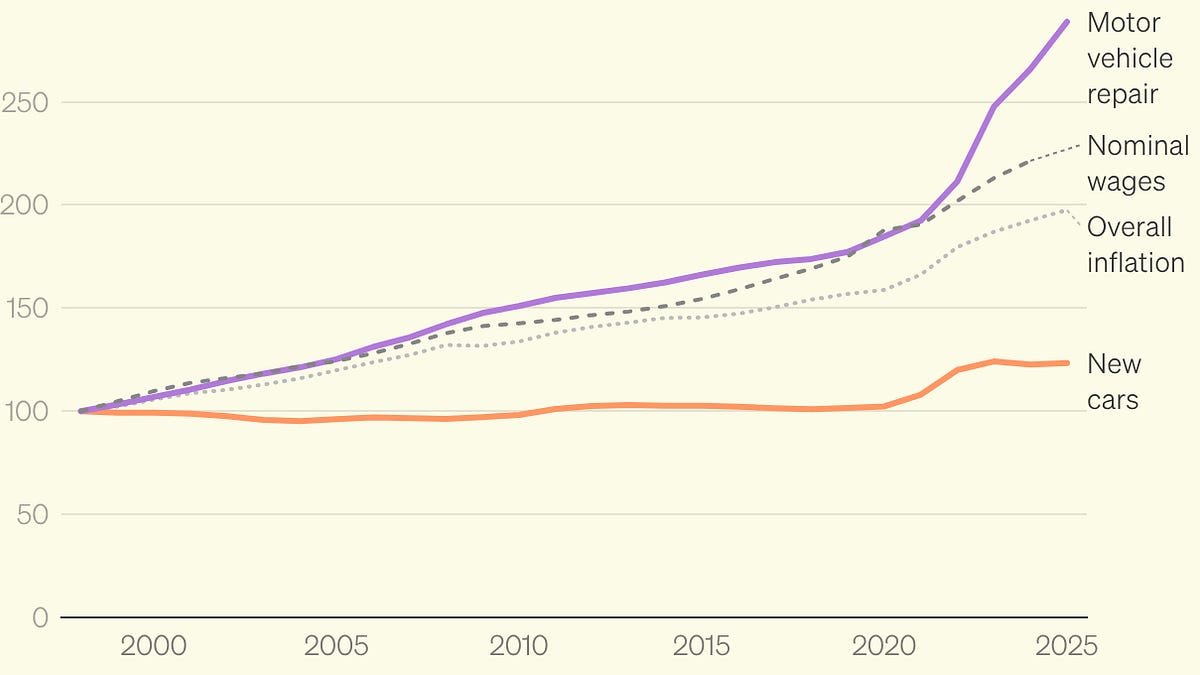

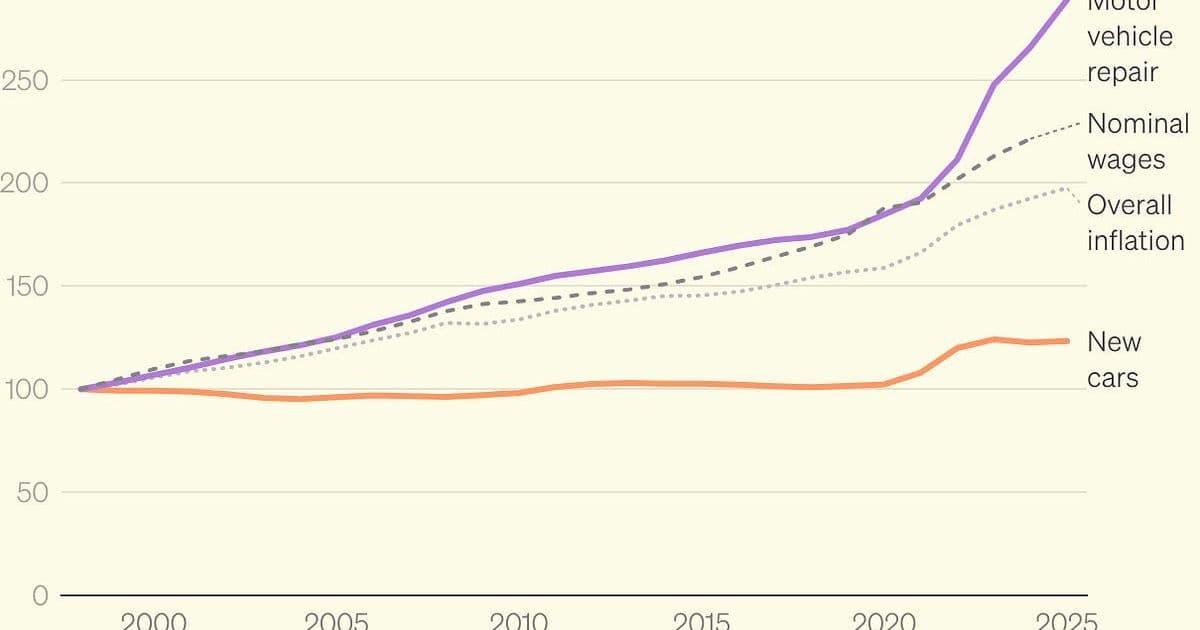

At its core, Potter's thesis rests on a fundamental economic principle: efficiency improvements have historically depended on repetition and volume. The article astutely contrasts the inflation-adjusted cost trends of cars versus car repair to illustrate this point. Cars, manufactured through repetitive, high-volume processes, have steadily become cheaper over time, while car repair—requiring situation-specific adaptation and lower volumes—has become increasingly expensive. This dichotomy reveals how our production capabilities have been constrained by the tension between scale and customization.

The evolution of automation technology represents a potential resolution to this tension. While dedicated machines have long been able to perform specific tasks repeatedly, flexibility has remained the elusive challenge. The recent convergence of advanced computer vision, sophisticated AI systems, and increasingly capable robotics suggests we may be approaching an inflection point where machines can adapt to variable environments and tasks in ways previously unimaginable.

The AWS analogy illuminates this potential transformation. Just as Amazon Web Services leverages massive economies of scale to provide computing infrastructure to millions of customers with varying needs, 'AWS for Everything' envisions physical production facilities that could similarly spread enormous capital investments across diverse production runs. These facilities would combine flexible automation with intelligent software control systems capable of dynamically routing materials and reconfiguring processes to accommodate an endless variety of products.

Evidence of this emerging model already exists in manufacturing. Companies like SendCutSend have demonstrated the viability of high-mix production by leveraging economies of scale. As founder Jim Belosic explains, their software can nest hundreds of different customer designs onto a single sheet of material, allowing them to run multiple jobs simultaneously with minimal setup time and scrap. This approach only works at scale—running individual jobs would bankrupt the operation. SendCutSend's rapid growth, reaching $100 million in annual revenue since its 2018 founding, suggests this model has significant commercial potential.

The concept extends beyond manufacturing into scientific research. The article references the potential emergence of 'AWS for biotech'—centralized automated labs that could spread the costs of expensive equipment across countless experiments for different researchers. This vertical integration could create a positive feedback loop: higher utilization justifies producing more inputs, which lowers per-experiment costs, attracting more customers and further increasing utilization. The result could dramatically accelerate scientific discovery by making advanced experimentation accessible to more researchers.

However, the 'AWS for Everything' model faces significant limitations and counter-arguments. Not all industries will benefit equally from this approach. The article notes that ghost kitchens—food preparation facilities serving multiple delivery-only restaurants—have not achieved the predicted success, suggesting that some industries may not have the necessary economies of scale or equipment cost structures to support this model.

Several critical questions remain about the feasibility of this vision:

Capital Requirements: The enormous upfront investment in flexible automation and intelligent control systems presents a significant barrier to entry. Only well-capitalized organizations could potentially build these facilities.

Specialization vs. Flexibility: There may be inherent trade-offs between specialization and flexibility. Highly specialized equipment often achieves better performance than flexible alternatives, potentially limiting the efficiency gains possible in a multi-purpose facility.

Transportation Costs: The model assumes that centralized facilities can serve dispersed customers economically, which may not hold true for all products, especially those with high transportation costs relative to their value.

Labor Market Impacts: If successful, this model could dramatically reshape labor markets, potentially displacing skilled workers in traditional manufacturing and repair while creating new roles in automation management and oversight.

Despite these challenges, the 'AWS for Everything' concept represents a potentially transformative vision for production. It suggests that the future may not be a simple binary between mass production and customization, but rather a continuum where large-scale facilities can efficiently produce both standardized goods and highly customized items through increasingly sophisticated automation.

As Potter notes, this model would not necessarily displace traditional mass production but would exist alongside it, serving different market segments and needs. The most likely candidates for early adoption appear to be capital-intensive industries with significant economies of scale, such as advanced manufacturing, scientific research, and certain specialized services.

The implications of this vision extend beyond economics to questions of accessibility and democratization. If production facilities can efficiently produce small batches or even one-off items, it could lower barriers to entrepreneurship and innovation, allowing more individuals and small businesses to bring products to market without enormous capital investment.

As automation continues to advance, the 'AWS for Everything' concept serves as a valuable thought experiment for understanding how production might evolve in the coming decades. Whether or not this specific model dominates, the underlying principles—leveraging economies of scale through flexible automation and intelligent control—will likely play an increasingly important role in shaping our industrial future.

Comments

Please log in or register to join the discussion