Asus has modified the liquid metal thermal interface material application on its flagship ROG Matrix RTX 5090 graphics cards following a recall, implementing a redesigned spread pattern with silicon-infused liquid metal to improve reliability and manufacturability.

Asus has implemented significant revisions to the liquid metal thermal interface material (TIM) application methodology for its $4,000 ROG Matrix GeForce RTX 5090 graphics cards following product recalls initiated last month. Technical analysis by overclocker Roman 'der8auer' Hartung confirms retail units now feature a completely redesigned TIM pattern addressing critical reliability concerns identified in early samples.

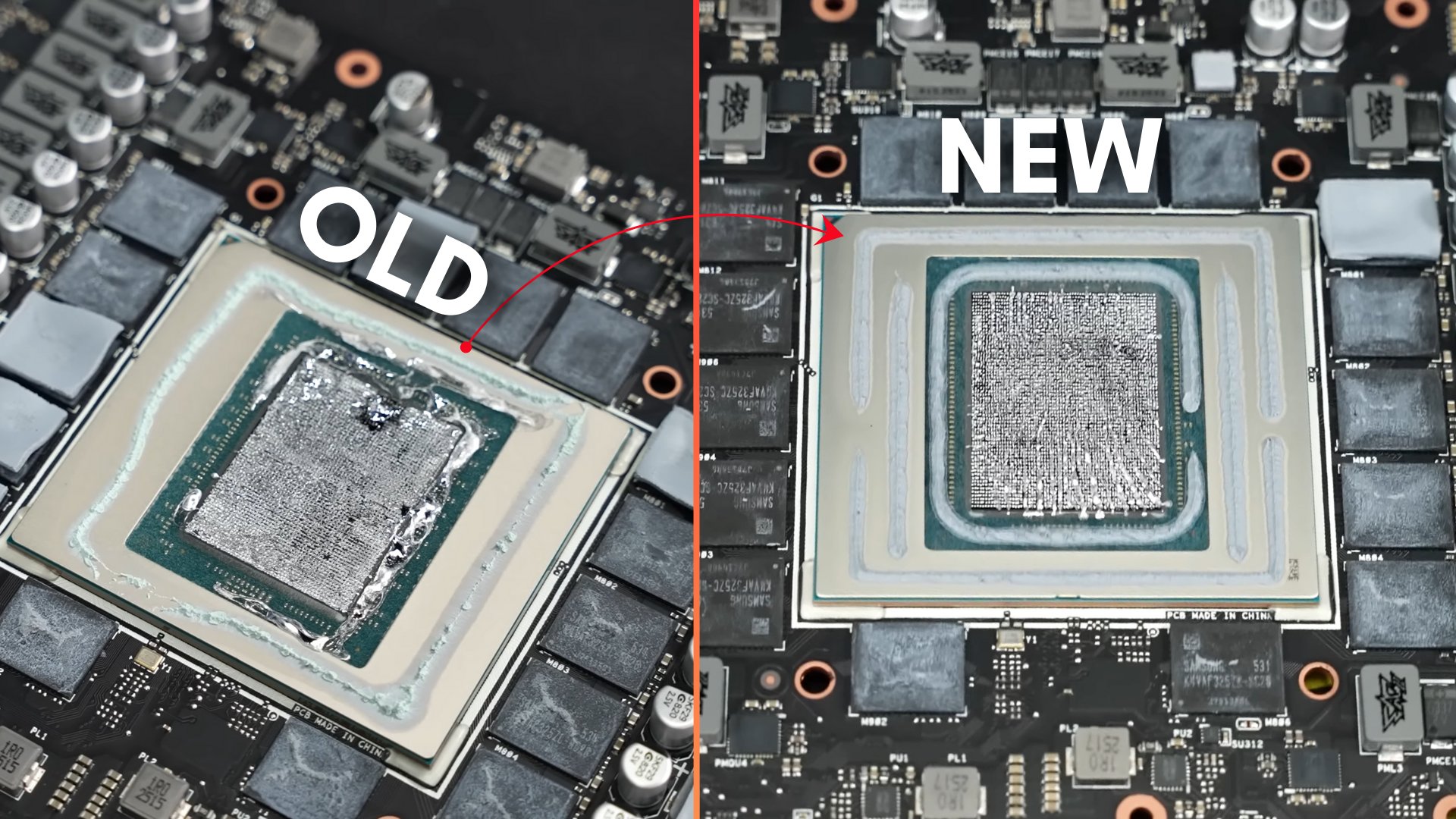

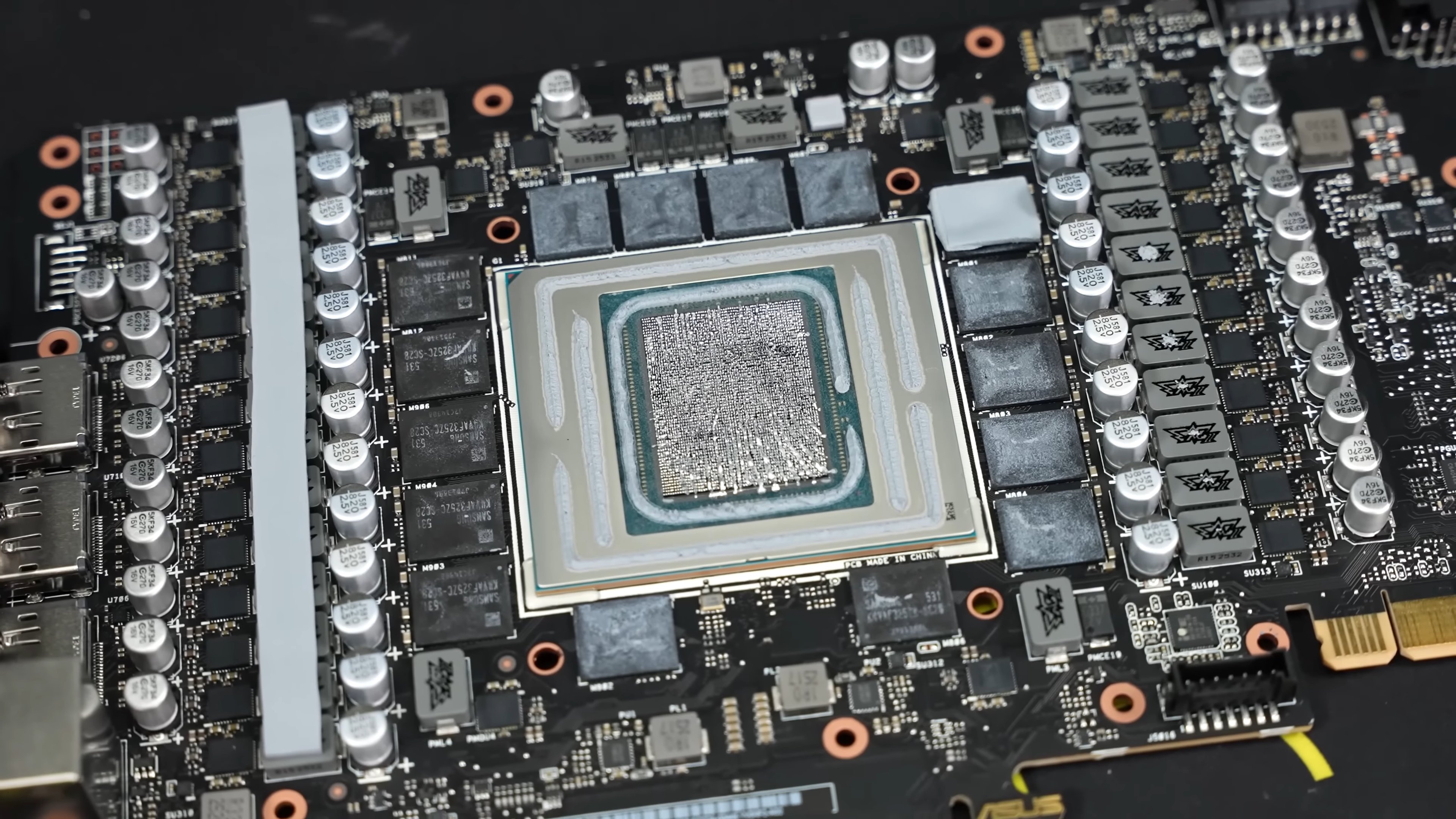

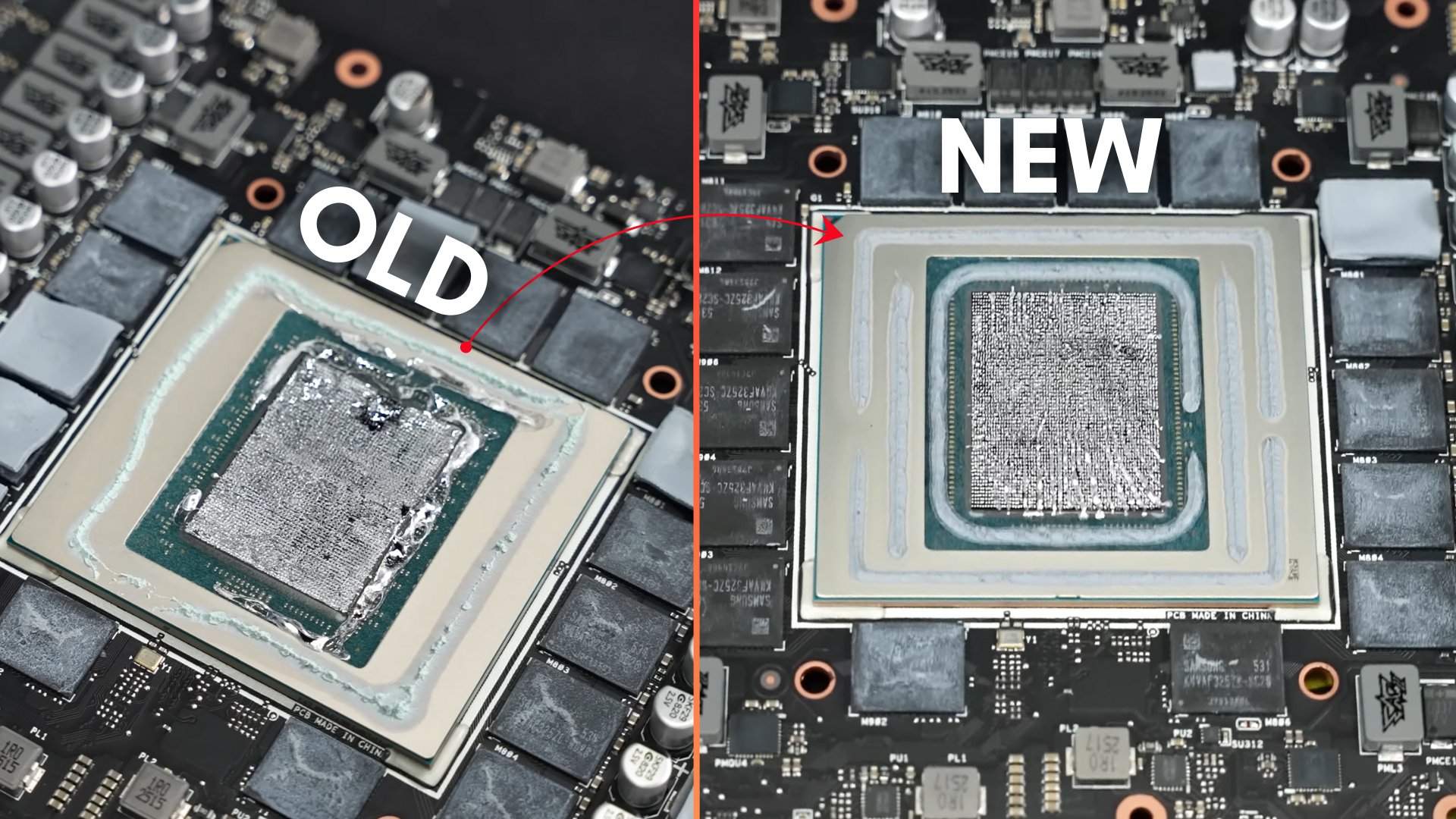

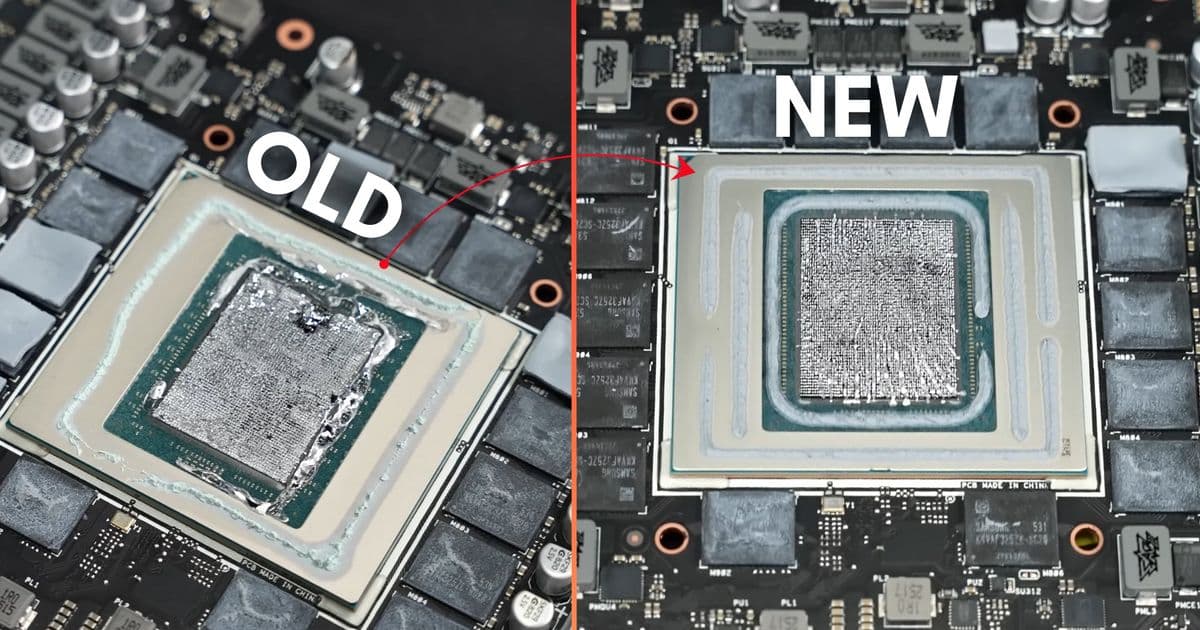

The original sample units exhibited an uneven ring-shaped liquid metal application that appeared manually applied rather than precision-engineered. Liquid metal offers superior thermal conductivity (typically 13-17 W/m·K versus 5-8 W/m·K for premium pastes) but carries conductive risks if leaked. Asus's revised design implements a multi-barrier containment system:

- Perimeter thermal paste barrier encircling the GPU die

- Two additional paste lanes forming containment channels

- Strategic cutouts accommodating thermal expansion

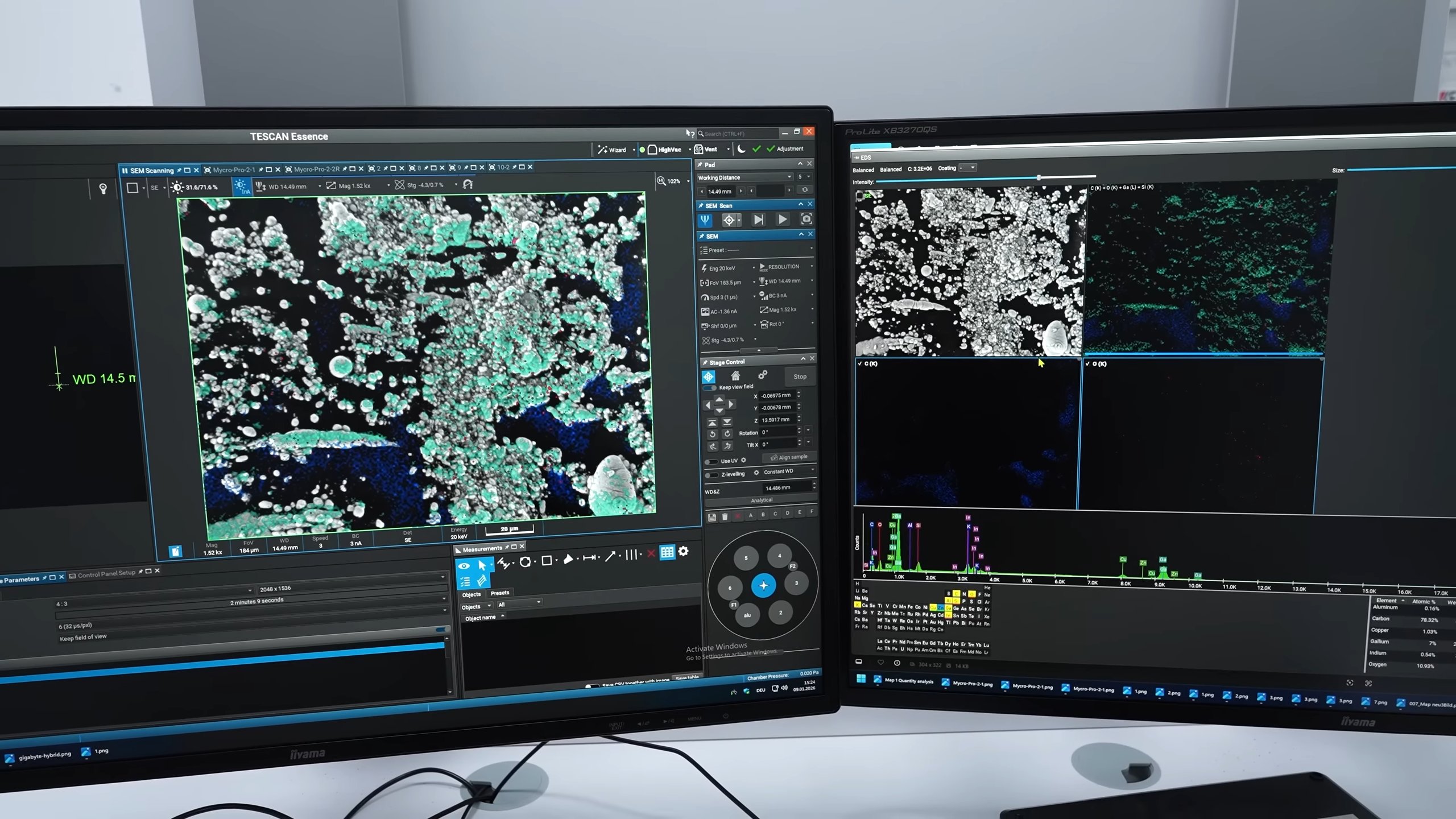

Material analysis via scanning electron microscopy revealed silicon oil infusion in the liquid metal alloy. This modification increases viscosity by approximately 40%, enabling automated deposition via precision printing techniques while maintaining thermal performance within 2% of pure gallium alloys. The silicon additive allows consistent replication across mass production lines - critical for high-yield manufacturing of this complex assembly.

Performance validation shows the revised configuration sustaining 798W power draw in FurMark stress testing with GPU temperatures averaging 64°C at 45% fan speed - a 5°C improvement over initial samples despite lower acoustic output. The containment system successfully prevents liquid metal migration during thermal cycling tests simulating 3 years of operation.

This recall represents a substantial logistical undertaking given the card's $4,000 MSRP and bespoke cooling assembly. Industry analysts estimate recall costs exceeding $2 million when accounting for reverse logistics, rework labor, and component replacement. However, the swift engineering response potentially prevents field failure rates that could have reached 8-12% based on der8auer's accelerated life testing of initial units.

The revision signals Asus's commitment to flagship product integrity despite cost implications. For context, premium TIM solutions represent 3-5% of total cooler assembly costs in high-end GPUs. This incident highlights ongoing challenges in scaling exotic cooling solutions for next-generation GPUs targeting 800W+ TDPs, where thermal interface reliability becomes increasingly critical to product lifespan.

Comments

Please log in or register to join the discussion