MetalPrinting's Gauss MT90 desktop 3D printer uses novel Paste Metal Extrusion technology to enable safe metal part production at room temperature, eliminating hazardous powders and high-temperature processes common in industrial systems.

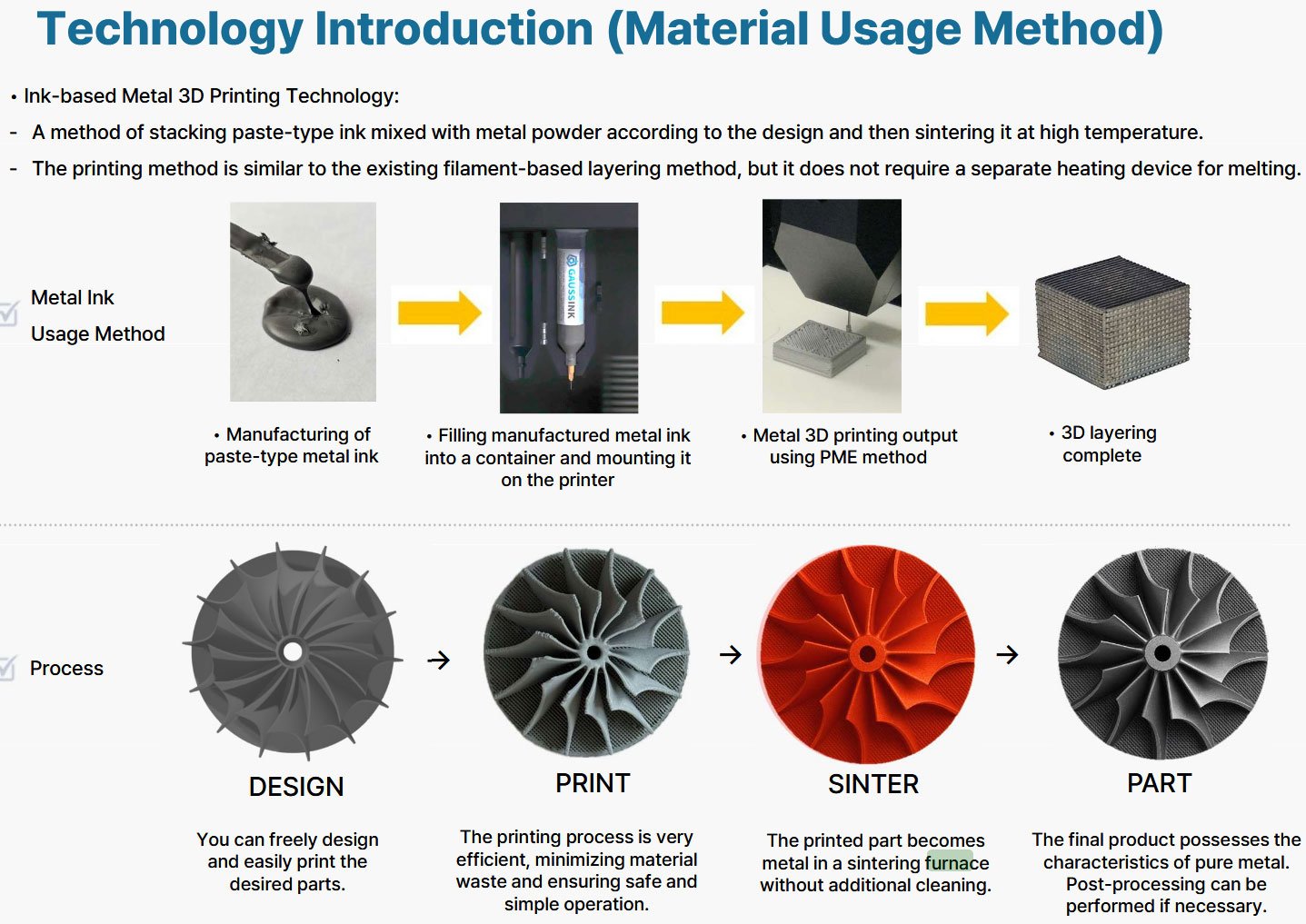

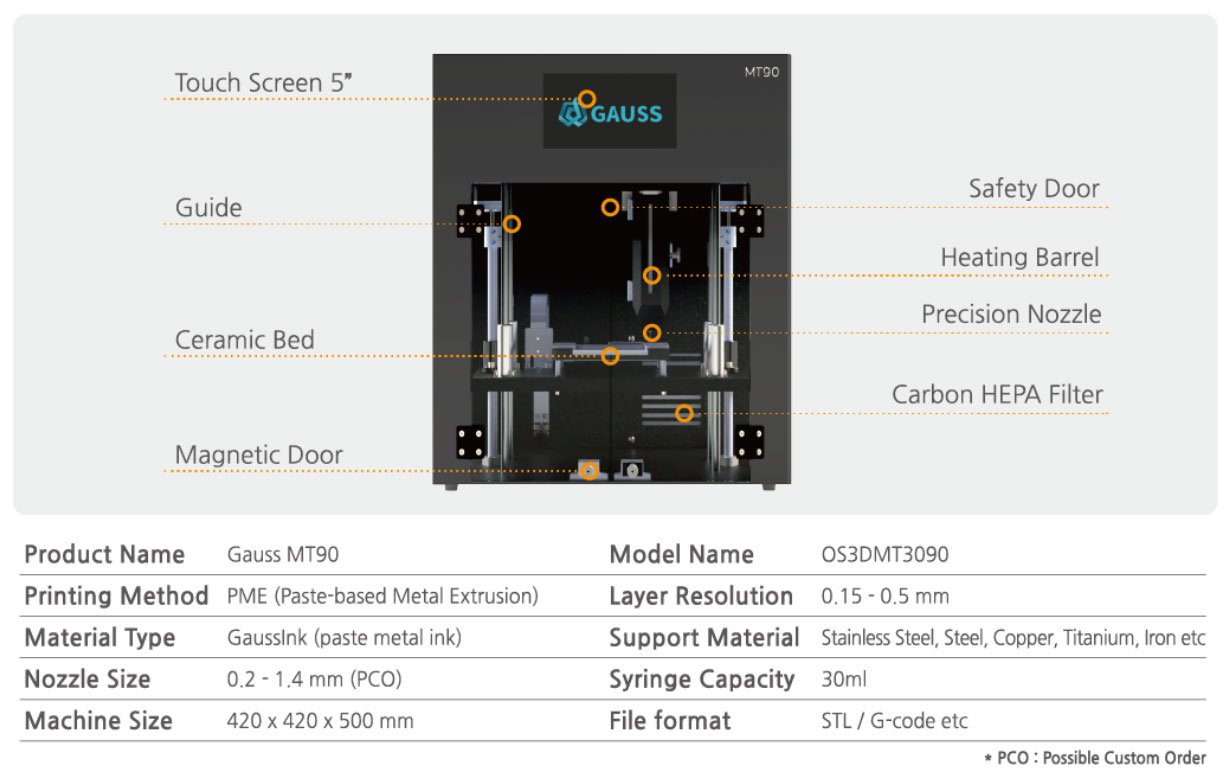

MetalPrinting unveiled its Gauss MT90 metal 3D printer at CES 2026, introducing a desktop-form-factor system that fundamentally rethinks metal additive manufacturing. Unlike conventional powder-bed fusion systems requiring specialized facilities, the Gauss MT90 leverages Paste Metal Extrusion (PME) technology—a patent-pending approach using cartridge-loaded metallic pastes instead of powders. This eliminates two critical barriers to adoption: the explosion risks from airborne metal powders and the energy-intensive high-temperature melting environments (often exceeding 1,200°C) used in laser or electron beam systems.

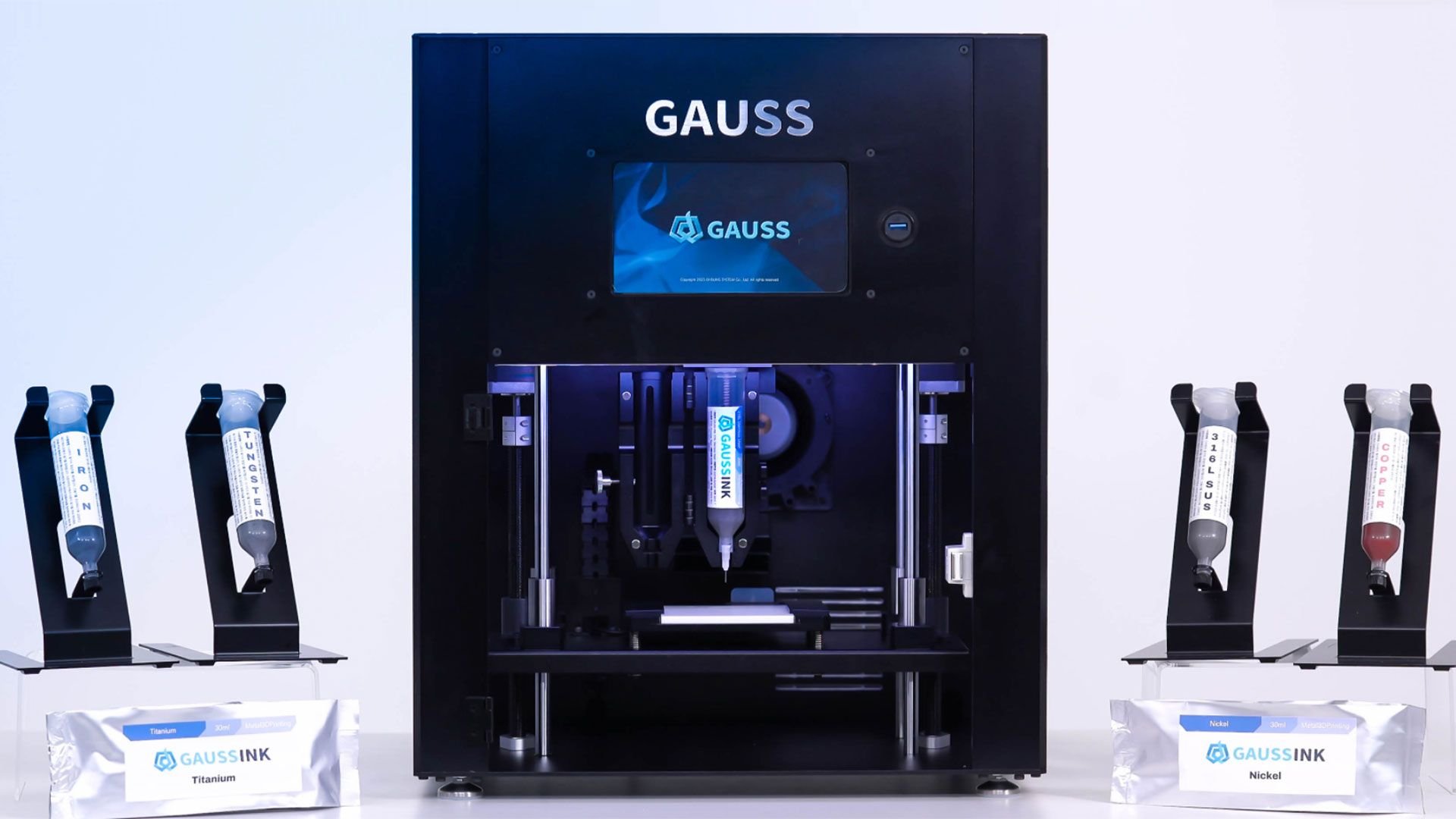

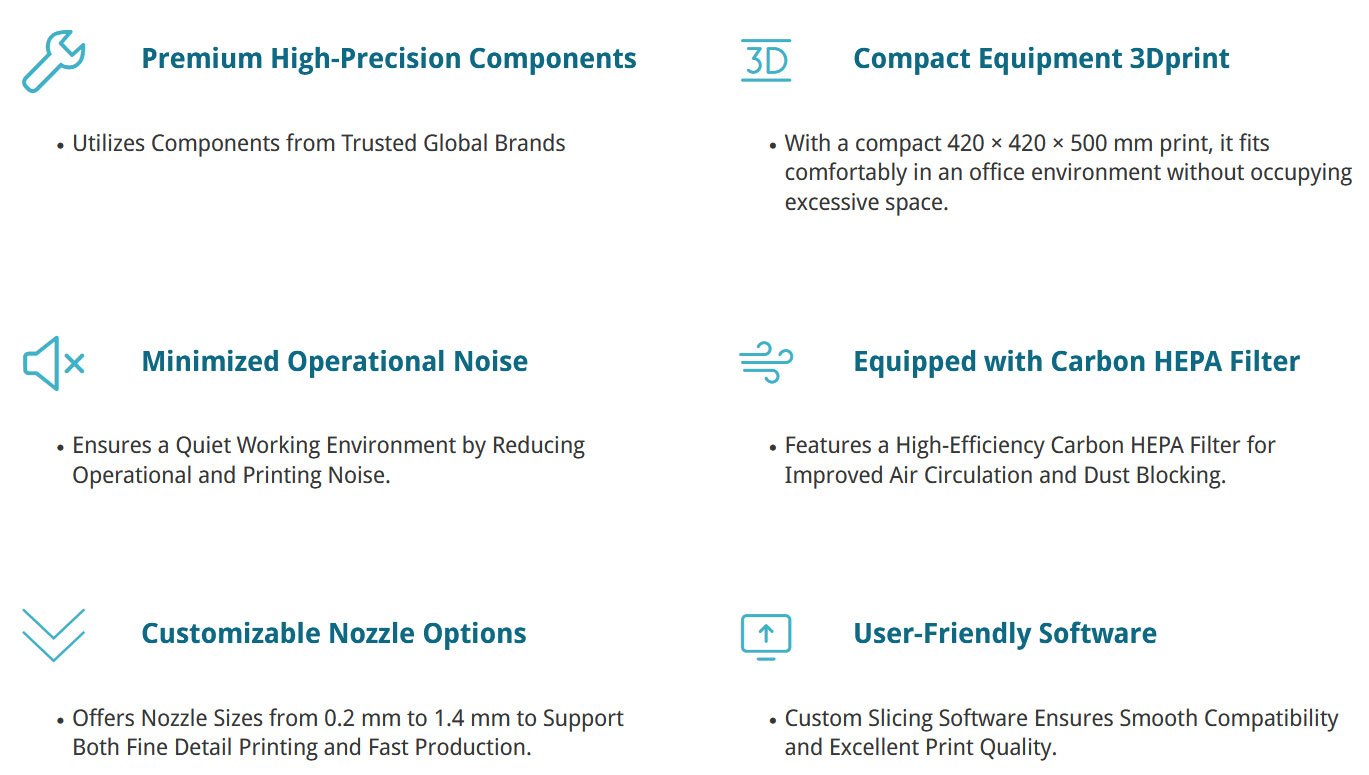

The Gauss MT90 operates entirely at room temperature, extruding viscous metal paste through a nozzle similar to polymer FDM printers.  This paste comprises metal particles suspended in a binder matrix, with available materials including stainless steel, copper, titanium, nickel, iron, and tungsten. Custom alloys are supported upon request. The printer’s enclosed chamber incorporates a HEPA filtration system to capture any potential particulate emissions, maintaining office air-safety standards. At approximately 40dB operational noise, it integrates seamlessly into engineering workspaces.

This paste comprises metal particles suspended in a binder matrix, with available materials including stainless steel, copper, titanium, nickel, iron, and tungsten. Custom alloys are supported upon request. The printer’s enclosed chamber incorporates a HEPA filtration system to capture any potential particulate emissions, maintaining office air-safety standards. At approximately 40dB operational noise, it integrates seamlessly into engineering workspaces.

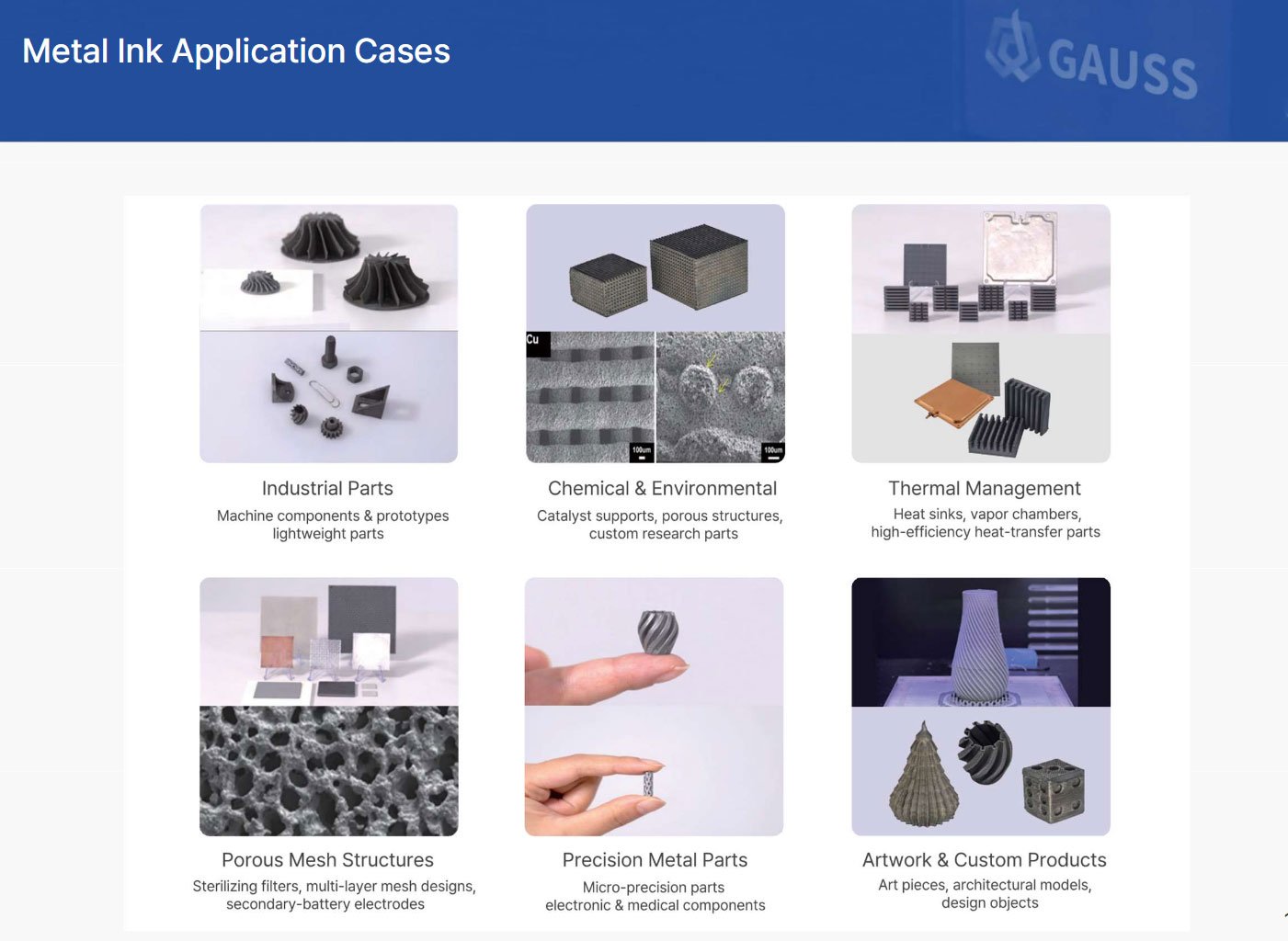

From a semiconductor manufacturing perspective, this technology offers compelling advantages for rapid prototyping and low-volume production. Fabricating copper heat spreaders, titanium fixture components, or tungsten shielding elements becomes feasible within R&D labs or cleanroom-adjacent offices without powder-handling protocols. The printer’s 7-inch touch interface and AI-monitored camera system enable real-time process validation, reducing scrap rates during development cycles. Crucially, it decouples metal part production from centralized industrial facilities, potentially shortening supply chains for specialized tooling.

However, PME technology introduces a critical post-processing dependency: sinter hardening. Parts printed by the Gauss MT90 remain "green" state post-extrusion and require secondary sintering in a furnace to densify the metal particles by diffusion bonding. MetalPrinting hasn’t disclosed sintering parameters or oven specifications, but typical metal paste sintering involves temperatures nearing 80-90% of the material’s melting point under controlled atmospheres. This adds processing time and equipment overhead, though sintering remains less hazardous than direct high-temperature printing.

Market implications are significant. Semiconductor equipment manufacturers could deploy Gauss MT90 units for on-demand production of jigs, calibration tools, or replacement components, reducing dependency on external machine shops. For context, Airbus previously trialed a high-temperature metal 3D printer on the International Space Station for part fabrication—a solution requiring extreme safety measures. The Gauss MT90’s powder-free approach offers a safer alternative for constrained environments. While pricing and availability remain undisclosed, its CES 2026 Innovation Award underscores industry recognition. MetalPrinting’s approach could accelerate metal AM adoption in sectors prioritizing safety and accessibility over maximum throughput.

For technical details, visit MetalPrinting’s official site.

Comments

Please log in or register to join the discussion