MIT researchers developed MorphoChrome, a handheld system enabling users to program iridescent structural color onto everyday objects through light exposure and resin transfer, bridging natural optical phenomena with accessible fabrication.

Structural color—the phenomenon responsible for the dazzling iridescence of butterfly wings and opal gemstones—has long fascinated scientists and artists. Unlike pigment-based colors, it relies on microscopic structures that manipulate light wavelengths to produce dynamic hues shifting with viewing angle. For decades, replicating this outside specialized labs required complex processes, limiting its accessibility. MIT CSAIL researchers now present MorphoChrome, a system enabling users to program structural color onto everyday objects through a handheld light-painting device and accessible fabrication workflow.

How MorphoChrome Works

MorphoChrome combines custom software with optical hardware roughly the size of a glue bottle. Users select colors via an intuitive RGB wheel interface. The device houses three lasers (red, green, blue) whose intensities adjust based on selections. These beams reflect off mirrors into an optical prism, merging into a single RGB output. This combined light exposes a holographic photopolymer film—similar to security holograms in passports—acting as the "canvas."

Animation showing a pendant transitioning through structural colors. Credit: MIT CSAIL

Animation showing a pendant transitioning through structural colors. Credit: MIT CSAIL

The fabrication process involves three steps:

- Light Painting: Users direct the laser onto the film, with exposure times calibrated per color (blue: 6s, green: 2.5s, red: 3s) due to wavelength-specific energy requirements.

- Resin Transfer: Objects are coated with epoxy resin, and the exposed film is bonded via 20-second UV curing.

- Reveal: Peeling away the film's protective backing leaves a permanent structural color layer.

Applications and Accessibility

MorphoChrome democratizes a process previously confined to labs. Examples include:

- Transforming a static butterfly pendant into an iridescent accessory with green, orange, and blue glimmers

- Creating golf gloves that shine green when held at correct swing angles

- Applying gemstone-like finishes to fingernails

The system prioritizes accessibility: components cost under $300, and the process avoids toxic chemicals. As lead researcher Paris Myers notes, "Users gain full creative agency over this material space. Instead of synthesizing colors in labs or hunting for rare materials, they experiment freely."

Technical Nuances

Color mixing follows additive principles—cyan combines green and blue, magenta blends red and blue. However, achieving luminosity requires precision. Blue's longer exposure compensates for its higher-energy wavelength. The holographic film's nanostructures reorganize under laser exposure, creating light-interference patterns that produce the final hues. Current limitations include light leakage from the 3D-printed housing and a color gamut the team aims to expand.

Research Context and Future Directions

MorphoChrome builds on MIT's legacy in programmable matter, including:

- Benjamin Miller's stretchable structural color research

- Thermochromorph (heat-activated color change)

- PortaChrome (reprogrammable surfaces)

Future work focuses on dynamic applications:

3D Light Fields: Encoding holographic messages (e.g., a 3D checkmark for document verification) using the film's full potential. "We're adapting our process for entire light fields in one film," explains researcher Yunyi Zhu.

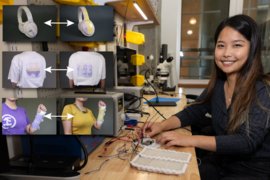

Yunyi Zhu working with MorphoChrome components. Credit: MIT CSAIL

Yunyi Zhu working with MorphoChrome components. Credit: MIT CSAILAdaptive Camouflage: Integrating structural color into soft robotics for environment-mimicking capabilities, like jungle terrain camouflage reprogrammable via remote control.

Industry Perspective

Paul Christie, CEO of holographics firm Liti Holographics (unaffiliated with the project), observes: "Simplifying structural color creation opens applications from jewelry to functional fabrics. This tool invites discovery."

MorphoChrome represents a convergence of natural inspiration and engineering—proving that complex optical phenomena can enter mainstream creation. The work was supported by the National Science Foundation and presented at ACM Symposium on Computational Fabrication 2025.

Comments

Please log in or register to join the discussion