A repair technician's YouTube video demonstrates how a user-damaged 12VHPWR connector on a $30,000 NVIDIA H200 data center GPU was successfully fixed, highlighting the critical role of proper handling in enterprise hardware and the ongoing challenges with the 16-pin power standard.

The data center GPU market operates on a scale of precision and cost that makes even minor hardware failures a significant event. A recent YouTube video from repair specialist northwestrepair provides a detailed look at the repair of a dead NVIDIA H200 Hopper GPU, a card with a retail value of approximately $30,000. The failure was traced not to a design flaw in the GPU itself, but to a damaged 12VHPWR 16-pin power connector—a component that has been a source of controversy in consumer graphics cards for years.

The incident underscores a critical point in enterprise hardware management: human error during installation or maintenance can lead to catastrophic failures. According to the technician's analysis, the damage to the H200's power connector appeared to be the result of user error, specifically, the power cable being inserted too aggressively, which bent and damaged multiple pins. This contrasts with the widespread reports of melting connectors on consumer cards like the GeForce RTX 4090, which were often attributed to design and manufacturing issues with the connector and cable. In this data center context, the root cause was mechanical damage from improper handling.

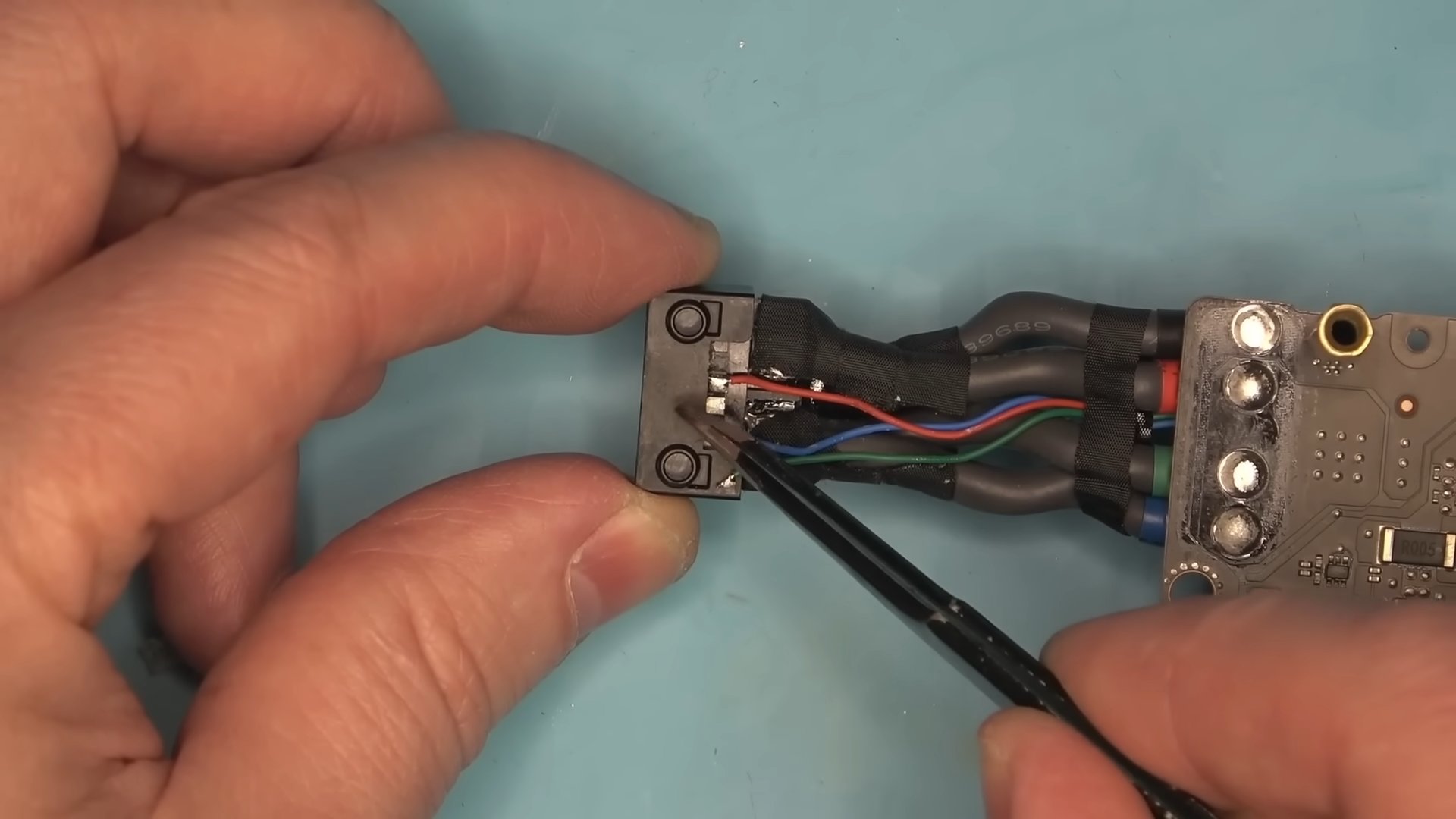

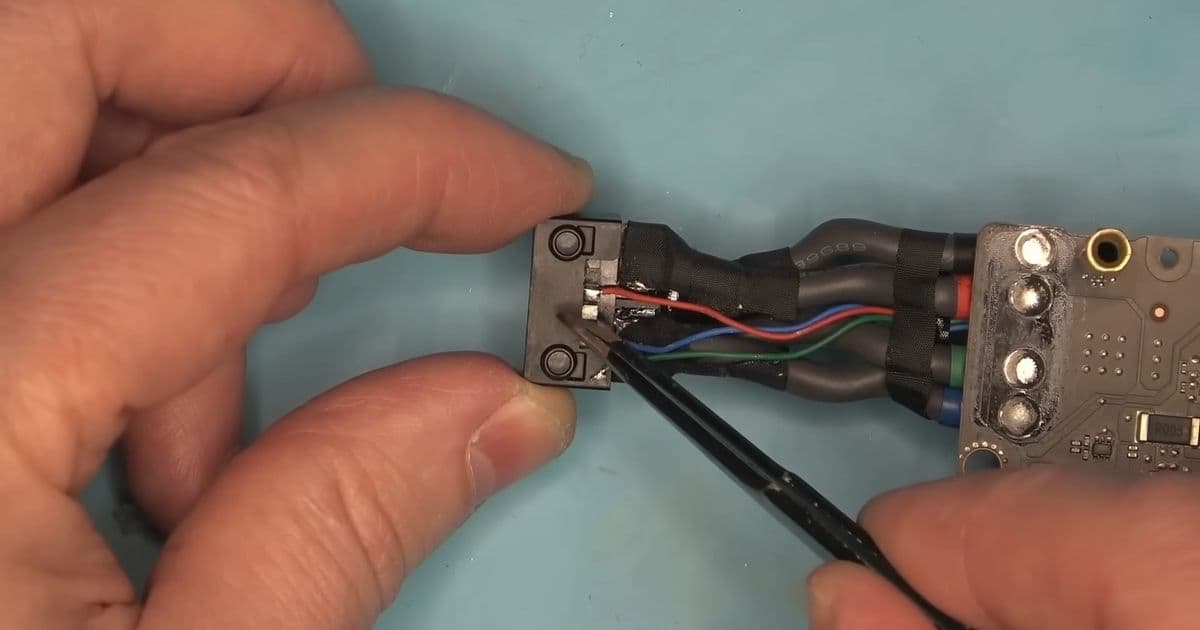

The repair process, as documented in the video, was intricate and required a deep understanding of the connector's pinout. The 12VHPWR connector, now superseded by the 12V-2x6 standard, includes four sense pins that communicate the cable's power rating to the GPU. These pins are essential for the GPU to operate safely. The technician's solution involved sourcing a spare 16-pin connector, carefully extracting the four sense pins, and soldering them onto the damaged connector on the H200's PCB. This required precise work to cut and shape the new pins to match the originals.

The repair was not without complications. The technician initially soldered the sense pins in the wrong order. To rectify this, they swapped the sense cables on the plug to realign the electrical connections with the misaligned pins. Despite this fix, the GPU still failed to power on due to an unrelated short on the PCB linked to the sense pin circuitry. Faced with this secondary fault, the technician opted for a pragmatic bypass: disconnecting the resistor that connects the sense pins to the GPU's main board. This effectively removed the sense pin functionality, allowing the card to receive power and operate. The technician noted that the customer confirmed the GPU was functional after the repair, though payment for the service was reportedly not received.

Technical Specifications of the Repaired H200

The specific model repaired was the PCIe-based H200 NVL variant, which is part of NVIDIA's Hopper architecture family. While the H200 is an older generation compared to the current Blackwell-based GPUs, it remains a powerful and expensive piece of data center hardware. Its specifications are formidable:

- Architecture: NVIDIA Hopper

- CUDA Cores: 16,896

- Streaming Multiprocessors (SMs): 132

- L2 Cache: 50MB

- Memory: 141GB of HBM3e (High Bandwidth Memory)

- Memory Bandwidth: 4.8 TB/s

- TDP (Thermal Design Power): 600W

- Interface: PCIe 5.0 x16

The 600W TDP is a key reason for the reliance on the 16-pin connector, which is designed to deliver up to 600W over a single cable, a significant increase from the previous 8-pin PCIe standard. This high power density is essential for the computational demands of AI and HPC workloads but also places greater stress on the power delivery system.

Market and Supply Chain Implications

This repair story has broader implications for the data center supply chain and operational practices. First, it highlights the financial risk associated with high-end accelerators. A single damaged connector on a $30,000 card can render the entire unit useless, necessitating either a costly repair or a full replacement. For large-scale deployments, the cumulative risk of such failures can be substantial.

Second, it reinforces the importance of standardized, robust handling procedures for enterprise hardware. Unlike consumer environments where users might be more casual, data center technicians require rigorous training to prevent physical damage during installation, maintenance, and transportation. The use of proper cable management tools and connector guides is not just a best practice—it's a financial imperative.

Finally, the incident keeps the spotlight on the 12VHPWR connector's reliability. While the revised 12V-2x6 standard aims to address the original design's shortcomings by making the connector more forgiving and the sense pins more robust, the fundamental challenge remains: a high-power connector with many pins in a small form factor is inherently susceptible to damage if not handled with care. The data center industry, which demands maximum uptime and reliability, will continue to scrutinize these components. The repair demonstrated by northwestrepair is a testament to the skill required to maintain such complex systems, but it also serves as a cautionary tale about the vulnerabilities in the power delivery chain for next-generation computing hardware.

For more details on the repair process and to see the technical work firsthand, you can watch the full video on the northwestrepair YouTube channel.

Comments

Please log in or register to join the discussion