As AI models grow more capable, the hardware to interact with the physical world remains a bottleneck. Linkerbot, a startup focused on dexterous robotic hands, has raised significant funding and is scaling production, betting that human-like manipulation is the foundational layer for embodied intelligence.

The race to build physical AI—machines that can perceive and act in the real world—has a clear bottleneck: the hardware. While large language models and vision systems advance rapidly, the dexterity required to manipulate objects remains a stubborn challenge. Linkerbot, a startup that has spent years developing high-degree-of-freedom robotic hands, is positioning itself at this critical intersection.

The company’s philosophy is straightforward: if AI is the brain, the body must catch up. "NVIDIA CEO Jensen Huang once said the next wave of AI would be physical AI," the Linkerbot team stated. "To us, the real bottleneck isn’t just computing power (brain). It’s how quickly the hardware (body) can catch up."

From Hardware to Intelligence

Linkerbot’s journey began with a focus on the mechanical challenges of dexterous manipulation. Over the past few years, the company has developed a full-stack system that integrates hardware, algorithms, and data collection. A key innovation is the use of a PEEK-based (Polyether Ether Ketone) reducer, replacing traditional metal structures. This material choice aims to make robots lighter and more energy-efficient without sacrificing strength.

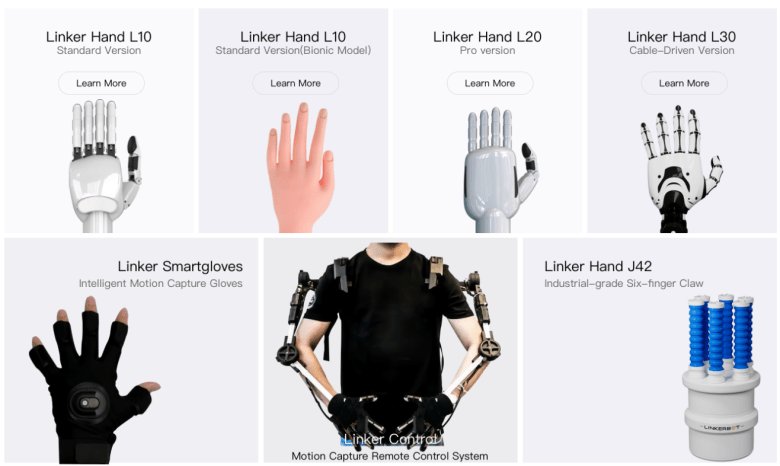

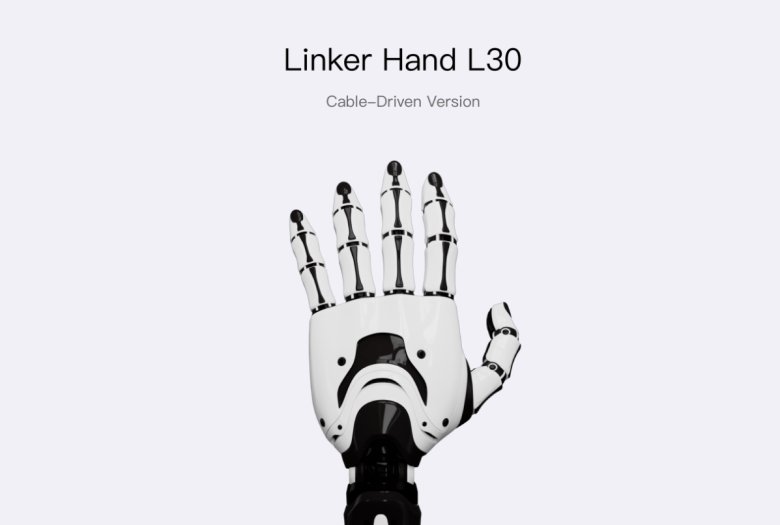

The company is not committed to a single mechanical approach. It explores multiple technical paths, including tendon-driven, linkage-based, and direct-drive systems. This flexibility allows them to tailor solutions for different applications, from delicate assembly to more robust tasks.

However, hardware alone is insufficient. Linkerbot is building the software layer to make these hands intelligent. The company has developed a physical world model and launched its own large-scale model, the Linker Creation Model. Coupled with Linker OS and a real-world reinforcement learning framework, the goal is to create a closed loop where data from physical interactions trains the models, which in turn guide the hands.

"Our goal is not just to build robotic hands, but to create the foundational infrastructure for embodied intelligence," the team said.

Real-World Applications and the Trust Problem

Linkerbot is targeting three core areas where dexterous manipulation is critical: precision manufacturing, healthcare and life sciences, and home services.

In factories, its hands are already being used for micro-component assembly in the automotive and electronics sectors. In agriculture, the company is collaborating with research institutions on breeding robots and high-tech farming applications. For eldercare and rehabilitation, the hands are being developed to assist with daily tasks like folding clothes or pouring coffee.

The transition from lab demonstrations to industrial deployment is where many robotics companies stumble. A software bug in a simulation is a minor issue; the same bug in a physical system can cause damage or injury. This reliability gap has long plagued dexterous robots, which are often perceived as fragile.

Linkerbot aims to solve this with a focus on industrial-grade durability. Its Linker Hand series has undergone rigorous testing, including crash and drop tests, and has contributed to setting national standards. The company has also validated its capabilities on the global ManipulationNet benchmark, completing a remote Peg-in-Hole manipulation task—a key test for fine motor control.

To facilitate research and development, Linkerbot launched Open TeleDex, a modular teleoperation system built around the "TripleAny" concept (any hand, any arm, any device). This open architecture allows developers to control robotic hands using familiar devices like VR headsets and exoskeletons, lowering the barrier for experimentation.

Scaling for Impact

The company’s customers fall into two camps: research institutions pushing the boundaries of dexterity, and industrial clients seeking reliable, scalable systems for production. For the latter, scale is the ultimate metric.

Linkerbot can currently produce over 1,000 high-dexterity robotic hands per month. The goal is to scale to 50,000–100,000 units per year by 2026. This manufacturing ramp-up is supported by significant funding. In December 2025, the company closed its Series A++ round led by Sequoia China and CCV (Creation Partners Capital).

The company believes that scale is where real impact begins. "When we deliver 100,000 dexterous hands, that means 100,000 dangerous, exhausting, or repetitive jobs can be taken over by robots," the team said. "That’s our long-term commitment to using technology for good."

The Global Landscape

Linkerbot’s reach extends beyond China. In North America and Europe, its products are used in research labs at universities like Stanford and Cambridge. The company is also paying close attention to aging societies in Japan and South Korea, where healthcare and eldercare applications are particularly relevant.

The team notes that cultural preferences matter. Many overseas developers prioritize open-source tools and interoperability, which influenced the design of Open TeleDex. This approach allows for broader collaboration and integration into diverse research and industrial ecosystems.

The Path Forward

Embodied intelligence is still in its early stages. The path from a single robotic hand performing a task to a fully autonomous system capable of complex manipulation is long and uncertain. However, Linkerbot’s bet is that progress must start with the fundamentals: building hands that can reliably interact with the world.

By combining durable hardware, intelligent software, and a focus on scalable manufacturing, the company is attempting to lay the groundwork for the next phase of AI. The challenge is immense, but the potential reward—a future where robots can safely and effectively operate in unstructured environments—makes it a critical frontier to explore.

For more information on their technology and products, visit Linkerbot's official website.

Comments

Please log in or register to join the discussion