This analysis examines how LCD technology innovations, geometric scaling effects in mother glass production, and relentless manufacturing optimizations transformed televisions from luxury items to accessible commodities over two decades.

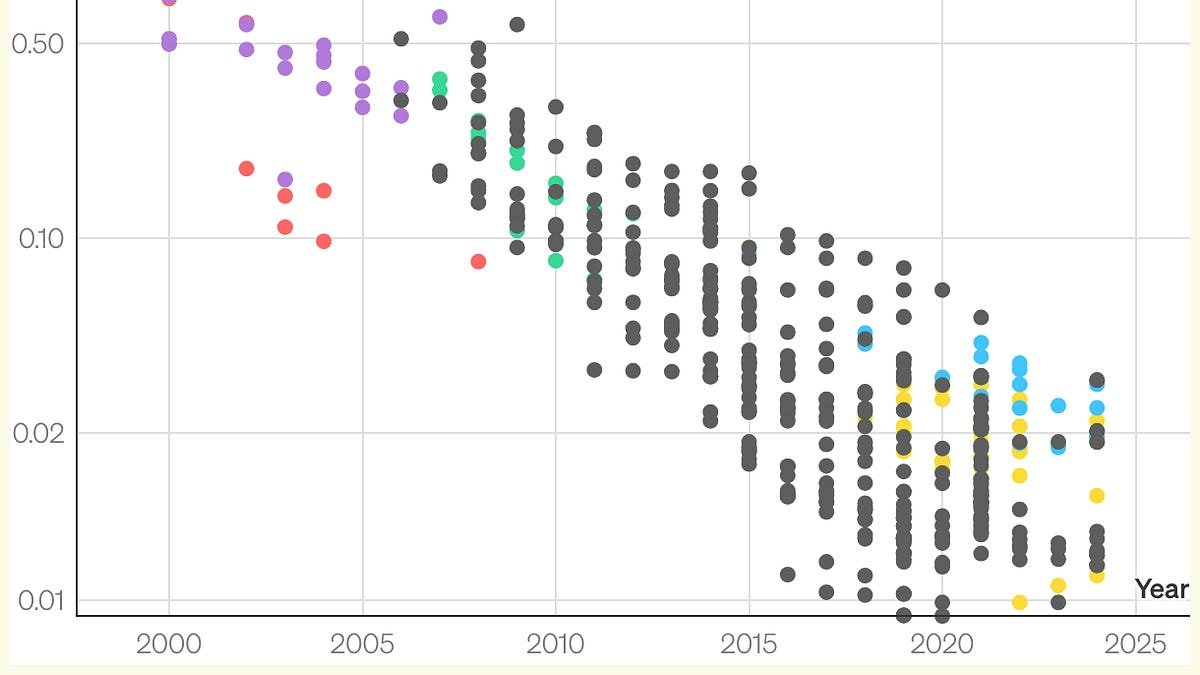

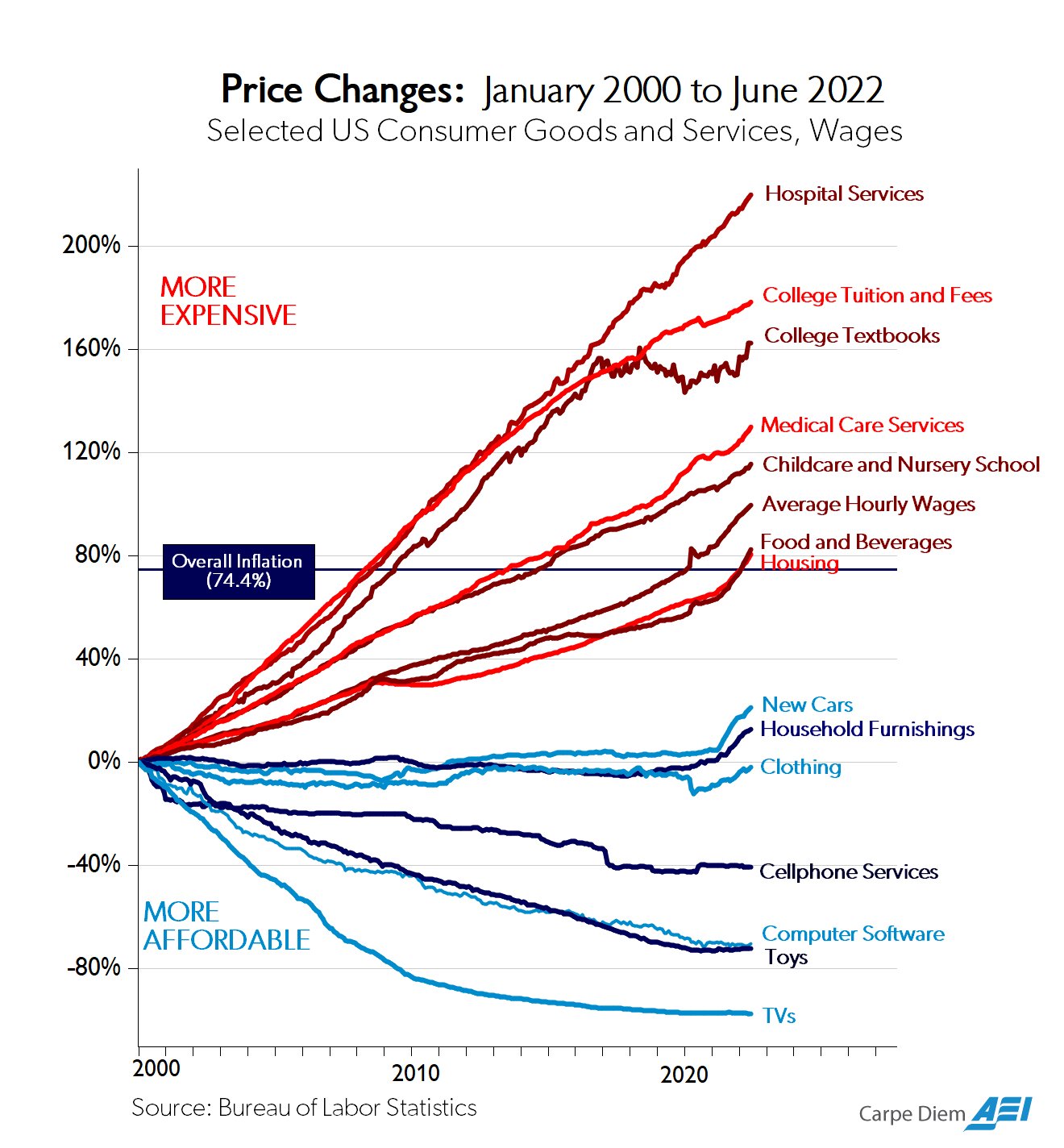

The precipitous decline in television prices represents one of modern manufacturing's most compelling efficiency narratives. While inflation charts starkly illustrate televisions as the century's most dramatically deflationary consumer good—plummeting over 90% in cost per area-pixel since 2001—the underlying mechanisms reveal a sophisticated interplay of materials science, process engineering, and industrial scaling.

Central to this transformation was liquid crystal display (LCD) technology's displacement of cathode ray tubes. Where CRT televisions dominated living rooms in 2003—with 27-inch models retailing for $150 while 20-inch LCDs commanded $800—manufacturing revolutions soon inverted that value proposition. The metamorphosis began with fundamental innovations: liquid crystals' light-modulating properties enabled pixel-level control through layered polarizing filters, thin-film transistors, and LED backlights. This technological foundation proved uniquely amenable to radical scaling.

The pivotal breakthrough emerged through geometric scaling of mother glass—the pristine silica substrates measuring over 3 meters diagonally in contemporary Generation 10.5 panels. As manufacturers expanded these sheets from Gen 1's 12x16-inch dimensions to modern behemoths covering 116x133 inches, equipment costs per panel area decreased by 80% between Generations 4 and 8. These monolithic substrates demanded unprecedented cleanliness protocols and logistical reengineering, exemplified by Corning constructing factories adjacent to assembly plants to eliminate transportation fragility. The physics of scale proved so potent that LCD glass expanded faster than semiconductor wafers, challenging lean manufacturing dogma that universally prioritizes small batch sizes.

Beyond dimensional scaling, parallel optimizations compounded efficiency: Plasma-enhanced chemical vapor deposition accelerated thin-film transistor production; masking steps reduced from eight to four operations; robotic automation pushed yields beyond 90%; and the revolutionary 'one drop fill' technique replaced days-long capillary absorption with minute-scale liquid crystal injection. Such innovations leveraged semiconductor manufacturing knowledge while adapting it to macroscopic dimensions—a convergence that transformed display fabrication into continuous-flow processes.

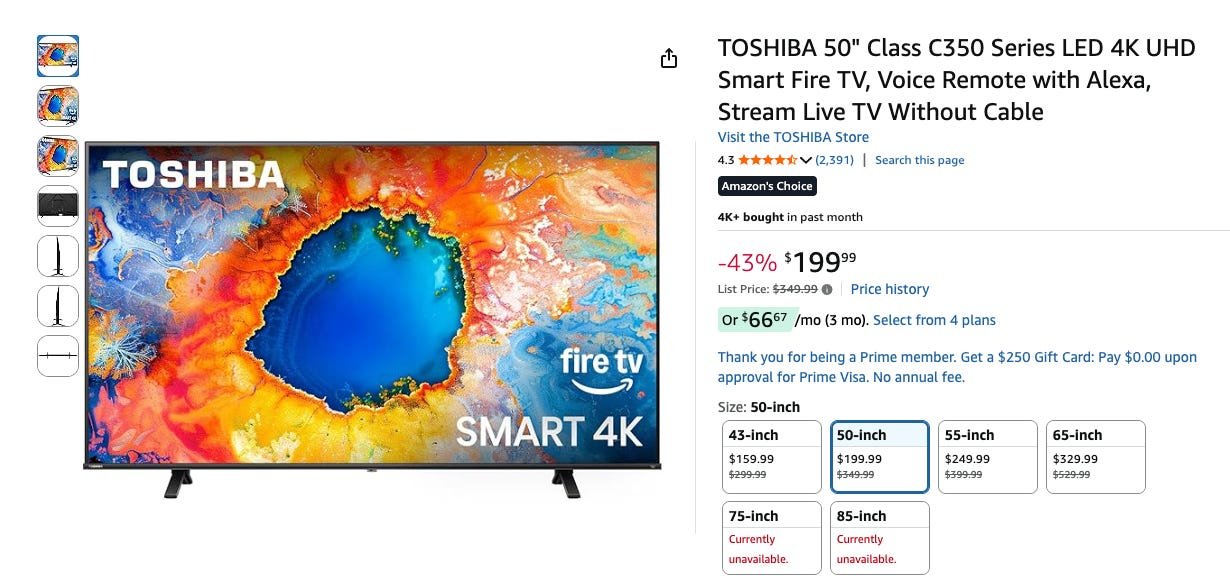

This technological evolution unfolded amid brutal market dynamics. Nationalistic industrial policies and multi-billion-dollar fabrication plants created economies of scale enabling million-panel daily outputs, yet simultaneously triggered what industry analysts termed a '25-year suicide pact' through margin erosion. The resulting affordability—where 50-inch displays now cost less than $200—demonstrates how manufacturing efficiency can democratize technology when geometric scaling, process innovation, and competitive pressure intersect.

A countervailing perspective notes that such hyper-deflation came at corporate cost, with manufacturers surviving on razor-thin margins despite continuous capital reinvestment. Nevertheless, television's price trajectory remains a testament to manufacturing systems achieving near-continuous efficiency improvement through multidimensional optimization.

Comments

Please log in or register to join the discussion